Carrasco International Airport, officially known as “Aeropuerto Internacional de Carrasco General Cesareo L. Berisso,” is located 11 miles (17.7 kilometers) east of downtown Montevideo, the capital city of Uruguay. With one million passengers per year, it is the only airport in the country that provides year-round international connections. As a result, it carries great symbolic value as the “front door” for many visitors to the country. With this distinction in mind, Puerta del Sur, the airport owner and operator, commissioned Rafael Viñoly Architects to expand and modernize the existing facilities with a spacious new passenger terminal to expand capacity and spur commercial growth and tourism in the region.

The firm’s design gives prominence to the public zones, including the secure runway-side concourse as well as the fully accessible roadside departure hall and terrace, by providing amenities such as open space, natural light, restaurants, retail, and landscaping, all housed beneath a gently curved roof 1200 feet (365 meters) in length. Arrivals and departures are separated by floor, with arrivals on the ground level, departures on the first floor, and vehicular access roads that service each level independently. A public, landscaped terrace occupies the second floor above the departure level, providing views of the runway and the main public concourse. The design also features a restaurant and space for commercial and cultural use.

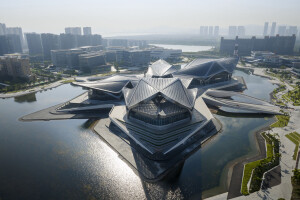

The gentle curve and low profile of the airport’s monolithic roof is inspired by the rolling dunes along Uruguay’s coastline. While the architectural solution for the Carrasco International Airport is modern in its conception of space, function, and structure, the roof is regionally inspired and draws its strength from its relationship to the surrounding topography. The building represents Uruguay’s transformation from an important regional country to an international destination for commerce and travel.

“In Uruguay, friends and family still come to greet you at the airport or see you off,” says Rafael Viñoly, “so this terminal provides great spaces for the people who aren’t traveling as well as those who are. The atrium, the main hall, the terrace, and the passenger concourse make this a dramatic and welcoming place for everyone.”

Features curved roof maintains a low profile on landscape strategic use of day lighting and views guides travelers through arrival/departure sequence design highlights public spaces for both travelers and non-traveling friends and family

Pull Quote from Rafael Viñoly “…dramatic and welcoming spaces for those who aren't traveling as well as those who are” —Rafael Viñoly

Full Quote from Rafael Viñoly "In Uruguay, friends and family still come to greet you at the airport or see you off," says Rafael Viñoly, "so this terminal provides great spaces for the people who aren't traveling as well as those who are. The atrium, the main hall, the terrace, and the passenger concourse make this a dramatic and welcoming place for everyone."

ADDITIONAL PROJECT INFORMATION Mission With one million passengers per year, Carrasco International Airport is the only airport in the country that provides year-round international connections, and as a result carries great symbolic value as the “front door” for many visitors to Uruguay. With this prominence in mind, Puerta del Sur, the airport owner and operator, commissioned Rafael Viñoly Architects PC to expand and modernize the existing facilities with a spacious new passenger terminal.

Design The Rafael Viñoly Architects design elevates the public zones, both on the fully accessible roadside departure hall and terrace and the secure runway-side concourses, and houses everything beneath a gently curved 1,200-foot-long (366-meter-long) roof. This gentle curve and low profile of this monolithic roof help integrate the building into its site. Inside the building, arrivals and departures are separated vertically—arrivals on the ground floor, departures on the first floor, with vehicular access roads for passenger drop-off and pick-up servicing each level independently. The roof provides a canopy over these access roads on one side of the building, and on the opposite side it opens up to give wide views of the runway.

The departures level is one large volume, in keeping with a long tradition of grand transportation halls. With glazing on all four sides and thin structural supports, the roof seems to float above the building. The departures level features the public concourse and the secure passenger concourse; these concourses are separated by the security checkpoint and immigration control at the center of the plan. After completing check-in and security procedures, departing travelers have access to duty-free shopping and restaurants in the waiting areas. Four fixed, elevated pedestrian bridges, accommodating a total of eight passenger gates, connect the passenger concourse to narrow- and wide-body aircraft and provide access to the apron for smaller planes.

A public, landscaped terrace occupies the second floor above the departures level. This terrace can be accessed without passing through security, allowing non-traveling friends and family elevated views of the runway and the departures hall and features a restaurant and space for commercial and cultural uses.

Arriving travelers pass through a mezzanine concourse, fully glazed to allow terminal and runway views that help orient newcomers to the terminal space, before descending to the baggage claim, customs, immigration, and further duty-free shopping areas. An open atrium adjacent to the street entrance visually and spatially links these two stages of a traveler’s journey, opening the ground floor to the monumental space of the main hall and bringing extra light to the ground level of the building.

Site Carrasco International Airport, officially known as "Aeropuerto Internacional de Carrasco General Cesareo L. Berisso," is located 11 miles (18 kilometers) northeast of Montevideo City, Uruguay. It is connected to National Route 101, a major thoroughfare, by means of a dedicated access road, which is teardrop-shaped in plan and encircles the main parking area. The new terminal will augment the old one, located 3,000 feet (one kilometer) to the west. Both terminals have independent access to the highway that connects with Montevideo and the eastern beaches, including the famous city and summer resort of Punta del Este. In keeping with airport construction, the site topography is nearly flat.

Program Carrasco International Airport differs from other airports in the emphasis placed on the duty-free retail space: the security checkpoint channels departing passengers directly into the duty-free shops both on the departure and arrivals sequence. Additionally, the public halls on both the departure and arrival levels were kept as expansive as possible, for a culture in which many family members and friends often turn out to send off or receive travelers.

Circulation Arrivals and departures are separated vertically for efficient circulation and security reasons. Circulation follows the typical airport sequence: a passenger leaves his or her vehicle at curbside, enters the terminal, passes through the main departures hall and purchases a ticket, clears the single security checkpoint at the center of the plan, and goes directly from security through immigration into the duty-free zone. This retail area is at the center of the secure passenger terminal, arranged lengthwise along the building adjacent to the runway, where passengers wait until boarding their planes. Four fixed, elevated pedestrian bridges, accommodating a total of eight passenger gates, connect the passenger concourse to narrow- and wide-body aircraft and provide access to the apron for smaller planes.

Friends and family (and passengers, before they pass through the security checkpoint) can ascend via elevator, stair, or escalator to the landscaped, second floor terrace, where they can eat in the restaurant and watch planes land and take off.

Arriving passengers enter the terminal from the jetway pedestrian bridges into a glazed mezzanine concourse above the ground-floor arrivals hall. After descending to ground level, they pass through immigration, another duty-free zone, retrieve their luggage from the carousels (these three spaces are laid out in a linear fashion), then pass through customs and out into the public hall where they can be met by friends and family.

Roof The roof is designed as a single shell spanning over the terminal and hovering above the ground; its shape is abstract in nature and the detailing reinforces this idea of a monolithic form. Cladding the roof structure are three separate materials: a white thermoplastic membrane on the roof, white metal panels on the exterior fascia and soffits, and a white stretched titanium-based vinyl membrane on the interior ceiling. All of these materials are coordinated in terms of co-planar alignment, color and detailing so that the aesthetic effect is that of a seamless, monolithic shell.

The roof appears to float above the narrow V-shaped structure at the perimeter of the departure hall, and the roof cantilevers 33.5m to the north, 26m to the south, and 15m at the east and west beyond its support on the sliding and rotating bearings at the structural foundations. Great efforts were made in the design phase to make sure that there were no penetrations (lights, sprinklers, smoke detectors, speakers, diffusers, grilles, access hatches, lifting lugs, tracks, outlets, etc) in the ceiling, and thus the ceiling and soffit, with their continuous, uninterrupted surface, reinforce the abstract, monumental scale of the roof.

Gutters along the north and west direct water to large catch basins hidden under the east and west cantilevered wings of the roof. The cross section of the gutter varies along its length and is about 2 meters by 1.25 meters. The location and size of the gutter accommodated capturing all roof runoff and these terminate into collection basins below grade under the east and west cantilevers of the roof.

Enclosure The sloped curtainwall that encloses the departure hall and terrace is hung from the roof structure. This added deadweight is beneficial to the roof structure whose live-load uplift forces are in excess of the downdraft forces of the roof, and this allows detailing that allows the interior and exterior soffits to precisely meet the glazing without the need for expansion and movement bellows. Tubular steel vertical mullions transfer the load into the V-frame structure with vertical slip joints to accommodate roof movement as well as at the base of the curtainwall where they are allowances for a maximum +/-5cm of movement.

The curtainwall on the north and south of the departure hall are parallel sweeping arcs in plan that tilt outwards at a 50deg angle from the horizontal plane; the curtainwall on the east and west are sloped 60 deg from the vertical plane. Thus, all of the glazed units are trapezoidal in shape on the north and south conical surfaces, and are rectangular on the east and west cylindrical surfaces, and studies were undertaken to reduce the overall number of different glass unit sizes to improve the constructability and reduce the cost in creating this unique geometry.

All of the lateral wind load on the glazing is transferred to vertical mullions which have an exterior cap that visually accentuates the splayed curtainwall. Each of the sloped glass units is supported on a horizontal shelf cantilevered from the vertical mullion with no horizontal mullion to transfer the lateral load into the structure as the glass unit itself is designed to structurally span between vertical mullions. Black silicone joints between stacked glazing panels, coupled with the use of black anodized spacer bars in the glass units, subverts the horizontal joints so that the geometry and scale of the sloped splayed mullions is visually predominant in the connection between the departure hall with the monolithic roof.

In order to maximize day lighting inside the main concourse of the terminal building a fully glazed cladding system has been provided along the entire perimeter of the terminal building. The plane of the glazing extends from the base of the V-columns to the bottom chord of the roof trusses. The V-columns act as the structural back up frame for the glazing system and are designed for in-plane deflection criteria of 1/600. In order to accommodate erection tolerances for the glazing system and allow erection adjustment special connection details accommodating movement in two orthogonal directions, have been provided for the mucllion connection to the backup frame.

Structure The unique roof, cantilevering beyond the building on all four sides, has an irregular plan profile with the width varying from 126 meters over the terminal building to 50 meters at its two ends. In addition, the roof, composed of steel trusses, has an irregular vertical profile with its two ends supported on grade and the height of the roof varying from 26 meters at its low point over the terminal building to 37 meters at its high point in the center of the departure hall.

Several structural schemes were explored for the roof of the terminal building by the design team including a steel arch system and a space truss system consisting of a network of pipes in a triangular grid. The structural system which was adopted for the roof is a series of 4 meter deep steel trusses provided in each orthogonal direction. The chords of the roof truss consist of wide flange section and double angle sections form the diagonals. The support structure for roof truss system comprises a series of bearings on grade provided at each end of the roof and a series of two inclined columns forming a V-shaped profile. These V-columns are 450mm diameter steel pipes and are provided along the entire perimeter of the terminal building.

The terminal building is a three-story concrete structure consisting of a one-way floor slab system supported by concrete beams, girders, columns and shear walls. The roof structure is supported on the perimeter of the terminal building at levels two and three. The foundation system is composed of isolated column footings supported on concrete piles. All footings are tied together by a network of grade beams.

For simplicity, the roof structure is divided into three sections – a central section over the main terminal building and two wing sections (one on each side of the central section). The central section over the terminal building consist of a series of north-south (N-S) directional truss frames which spans 70 meters over the terminal building with a maximum cantilever of 33.5 meters on the north side and 26 meters on the south side. These frames have an average spacing of 9 meters at the center, and in-fill gravity framing consisting of wide flange sections spanning between N-S directional frames, supports the roofing membrane and provides bracing to the truss chords. The V-columns supporting the roof frames are in turn supported on the terminal building at Level 2 (Departure Hall level) and Level 3 (Terrace level).

Each of the wing structures consist of a series of east-west (E-W) directional trusses. These E-W trusses with an average length of 92 meters are supported by V-columns at the terminal building and by bearing supports on grade. Bridging trusses are provided at each panel point of the E-W trusses. The bridging trusses overhang beyond the edges of both trusses of the wing for the wing structure to support the huge gutter that runs the entire length of the roof. An intermediate N-S directional truss frame is provided at approximately one-third span from the bearing supports to reduce the span of the E-W trusses, and the intermediate truss frame consists of a bridging truss with four column supports.

The lateral bracing system for the roof structure in the N-S direction consists of truss frames in the central section and intermediate truss frames in each of the wing sections. East-West (E-W) directional diaphragm bracing was provided from each end of the roof structure at both top and bottom chords of the roof trusses. The lateral system in the E-W direction consists of four directional frames in each of the wings and two E-W frames. Diaphragm bracing is provided in the N-S direction to transfer the load to these N-S frames.

The combination of wind and gravity forces govern the design of the roof structure. A wind loads were based on a wind tunnel testing study. The wind tunnel reported a total uplift force of 18,000 kN (kilonewton, average 59 kg/m2), a total downforce of 7000 kN (average 25 kg/m2) and a total horizontal force of 1600 kN. The total dead load of the roof structure and roofing assembly is approximately 122 kg/m2.

Lighting The lighting was used to highlight the principal elements of the architecture. It also complies with the highest standards of energy efficiency. The most important element to illuminate is the large interior volume (a ceiling of 162 x 87meters) which is up-lit so as to provide an even distribution of indirect light within the main terminal space and so as to accentuate the floating nature of the roof .

The owner and authorities with jurisdiction required higher illumination levels than usual in order to meet international standards for lighting. In order to achieve these goals and comply with conservative targets for energy consumption, the design team specified energy-efficient light fixtures.

Three types of lights have been used in the terminal: a) Asymmetric spotlights for the roof, soffit, departure hall, check-in area and the terrace. b) Continuous fluorescent tubes (T8 of 36 and 58w color 83) for the departure concourse, arrival hall, immigration halls, customs and baggage claim areas. c) Groups of downlights and spotlights using metallic ceramic halogen lamps (70w or 150w - color 83) at the commercial areas.

The departure hall and terrace lighting has been designed using indirect reflection of the large roof, and as 300 lux were specified in the project brief, 280 asymmetric spotlights with 400W halogen metallic lamps were required to achieve this lighting level. These fixtures are mounted to the structural V-frames and pointed towards the roof with an overall density of 14 w/m2, and even though the space is illuminated by indirect lighting, this is well under the acceptable values for energy efficiency.

The exterior soffit of the roof is illuminated with the same type of spotlight, although with fewer fixtures; 370 luminaries have been used for the soffit, and the areas which are lit by indirect reflection from the exterior soffit are designed for a medium level of 80 lux.

Electrical The new terminal of Carrasco International Airport is supplied by a 30KV service from the energy supplier with the expected total potential of 4MVA. From the connection point, located 2000 meters away from the new terminal, there are two high tension cables (one normal and one redundant) to the building substation. The transformer substation has a primary voltage of 30kV and secondary voltages of 0.4 and 0. 23kV with three dry transformers of 2MVA each, and these transformers feed two main electrical switch boards and the air conditioning mechanical room board.

The building has two backup power generators of 1100 KVA each, and in addition, two UPS (300kVa and 160kVa) have been installed for the lighting supply that allow for 50% electrical power service in the event of an electrical blackout.

Mechanical The cooling plant consists of 2 (two) 700 Ton water cooled centrifugal chillers with a third unit to be installed in the future, and the cooling plant was designed with full integration into the architectural design so that it is not visible to the public. Heating is provided by 2 (two) 6,000,000 Btu/h gas boilers.

Primary constant flow and variable secondary flow circuits supply chilled and hot water distribution systems to the AHUs and fan coil units. All main AHUs employ free cooling and are located in three mechanical rooms at the basement from where low velocity air distribution systems keep all areas of the terminal fully conditioned at optimal comfort levels and provided with proper ventilation.

Concealed high pressure fan coil units and small air distribution systems are the standard for all offices, and high efficiency inverter split systems are used for IT areas as well as for the airport jetways and bridges.

Sustainable Design The cantilevered roof provides shading of all interior spaces while the abundant glazing with low- emissivity coatings provide high insulation performance while allowing natural light into the building and providing views to the exterior for those inside the terminal. The white membrane roof further reduces the heat island effect and the collected rainwater serves the irrigation system while underground aquifer water is used in both the water closets and the cooling tower.

Free cooling cycles are provided in the air circulation system that allow the direct use of outdoor air during the spring and fall seasons. Ventilation air levels exceed the requirements of ASHRAE 62 and provide exceptional indoor air quality performance, and insulation, efficiency, ventilation, and natural ventilation provisions all exceed local code requirements. Environmentally responsible R123 refrigerant is used for centrifugal chillers and the high-efficiency refrigerant R410A is used for the DX (direct expansion) systems.

Life cycle cost strategies All cost estimating and analyses were conducted by the client and per the client's request, these assessments were not shared with the design team.