We use cookies to provide the best site experience.

Start your own protein bar production business. Fast and easy with

TF bar extrusion machine.

TF bar extrusion machine.

Learn more about our automated production line including extrusion, glazing, and primary packaging. Add end of line machinery upon your choice to have bars packed in cartons or display boxes.

Get more information about TF bars extrusion technology

Look how it works

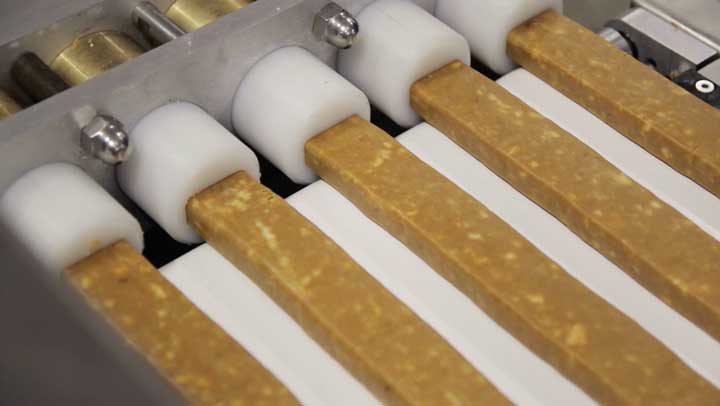

Watch our short video about TF bars extrusion machine combined with ultrasonic cutting system.

Focus on opportunities

Enter a promising niche

With steady growth with a CAGR of over 5%.

Get predictable ROI

And production deployment with low investments

Expand your product portfolio

To get even more outreach for your brands

Create a useful product

With high demand worldwide

Have fully automated production

Cutting expenses on labor and cost of running

Pay attention to protein bar global market

The protein bar is light functional snack food based on cereals and fruits. It perfectly satisfies hunger, supplements the usual diet, and is suitable for people who exercise and control their weight.

Market value

Experts say the size of the global protein bar market is to reach USD 7,07 billion by 2029 from USD 4,68 billion in 2022.

Market Growth

The global protein bar market will be exhibiting a CAGR of 6,1% during the next decade.

Simple product

The protein bar is a simple product without any preferences for complex processing machinery or ingredients.

For whom this market is?

Here are only some of the main players in the bar production market using our extrusion technology.

- HoReCa

- Startups in the food FMCG sector

- Local SME and major enterprises

- White-label goods producers for retailers

- Budget-friendlyFor a quick start you only need a stable mixture recipe, a room, and an automated line of equipment.

- Soon paybackReasonable prices for equipment and money-saving technology make the ROI period predictably short, compared to other industries.

- Stable demandHealthy nutrition trends with the rise of sports lifestyle as a grant of welfare make protein and other fitness bars highly demanded among wide auditory

- Variety of choiceThe global fitness bars market will show CAGR of 4,1% up to 2028.

This means you have a growing market where you have a huge variety in choice of product options you offer: taste, form, and packaging design.

Who is your customer?

Starting the production of protein bars is an excellent option to attract a target audience with a stable demand for fitness and dietary foods.

B2B Segment

- HoReCa & retail,

- E-commerce: sports nutrition stores, supermarket chains, marketplaces

- Sports facilities: fitness centers, sports clubs, playgrounds

- Pharmacies and healthcare centers

B2C segment

- Athletic people between the ages of 16 to 35

- Professional athletes and those on sports nutrition or protein diets

- Maintaining their figure, control their weight or following a proper diet

- Vegans

Our experts are ready to help

Submit your details to carve out a niche for protein bar production in a growing market.

How not to miss the trend and quickly deploy the production of bars?

The fine solution is a fully automated line for the turnkey production of snack bars.

HFFS packaging for ready product

Ultrasonic or string cutting of bars into size

Extrusion of the mass through the nozzels

Loading of the product mass into the bunker

The core of the automated line –is the extruding machine

The Sigitaspak universal auger extruder is a molding machine for the production of pralines, fruit, protein, and similar confectionery products.

Book your test run

Do you have a unique recipe of your own and are ready to test it on our equipment? You only need a batch of 15-20 kilograms of mass for the test run.

What to extrude?

The machine allows extruding bars of several shapes with differences in density, consistency, and composition of confectionery masses, both with or without inclusions: candy and protein mass.

Advantages of TF extruding equipment

Our equipment is winning customers' preference to its' robust design and usability.

Fully automated

You need only 1 operator for running the automated line reducing the labor costs

Ease of running

Intuitive HMI interface of each piece of equipment included in the bar production line

Small footprint

Compact size of the equipment allows to deploy the production process in small areas

About SigitasPak FZE

Join the global community of our clients and partners that grows every year. Let’s bring the value to each other and evolve the packaging industry together.

You're in a good company

SigitasPak brand, which successfully entered the packaging market back in 2011, is proud to present an official office and showroom in the hub of the Middle East - Dubai. Under this name we unite three packaging manufactories and offer not only a wide range of filling, packaging, depositing and weighing machinery, but also the experience of over 30 years. Our experts have been providing solutions to complex requests worldwide, whether it is an economical approach for new companies or fully automated lines for industry giants.

1000+ installations

worldwide annually

worldwide annually

CE certified equipment

international

service support

service support

ISO 9001:2015

certified production

certified production

sales and service office network in 6 regions

35 years

expertise in packaging

expertise in packaging

Our customers worldwide choose us due to trusted services

Integrated solutions

Our in-house facilities give us a unique opportunity to deliver robust flexible modular solutions based on cutting-edge technologies to guarantee seamless turn-key integrations with processing equipment of our customers.

Carousel bottling machine with TRIBLOCK technology for rinsing, filling and capping of products into different types of bottles.

Bottling

Cup fillers

Rotary and inline cup filling systems for products of all kinds. Variety of options to get solution suitable for most complex projects.

We offer dozen of solutions in horizontal flow-pack packaging technologies to meet the needs of complex global market.

HFFS

VFFS

Vertical baggers for speed packaging of free-flowing products offering wide variety of bag styles and marketing options.

Dosing systems

Variety of weighing systems for virtually every task in dosing of different products from grains to pasta and frozen produce.

Stick & Sachet

Multilane vertical packaging machines for stick and sachet packaging of dry, liquid and viscous products.

Cartoners & EOL

Cartoners, end loaders, traypackers, shrinking tunnels and other end-of-line equipment for secondary and logistics packaging.

PFS

Machines for bagging into stand-up doy-style pre-made pouches for dry, liquid and viscous products.

Check 200+ models of cutting-edge machinery for packing virtually every product you can imagine to meet every market demand

Our product range