Abstract

Titanium alloys have excellent specific strength, outstanding corrosion resistance, and good biocompatibility, which are widely used in mechanical and medical fields such as compressor disc, blade, stator, and hip and knee joint. Titanium alloy workpieces must be machined to obtain specific shapes. However, the machining marks inevitably exist on the titanium alloy surface, which have a poor effect on the performance of workpieces. Therefore, polishing is scheduled at the subsequent process to remove the machining marks. Because titanium alloys are typically difficult-to-polish materials, the polishing surface quality and efficiency require to be improved further. To have an in-depth and comprehensive understanding of the polishing technology of titanium alloys, this paper reviews systematically the material’s polishing mechanisms and processes. To date, various fundamental mechanisms, including mechanics, heat, optic, electricity, magnetism, ultrasound, and chemistry, are employed to polish titanium alloy surface. On this basis, four types of polishing techniques were developed (i.e., mechanical polishing, high-energy beam polishing, chemical polishing, and compound polishing) to improve the high surface integrity of titanium alloys. Furthermore, the advantages and disadvantages of each polishing technique are discussed in detail from the views of model, optimization, equipment, efficiency, surface quality, and cost. Finally, this paper proposes the future development directions of the polishing techniques of titanium alloys.

Similar content being viewed by others

Data Availability

Not applicable

Code availability

Not applicable

References

Veiga C, Davim JP, Loureiro AJR (2012) Properties and applications of titanium alloys: a brief review. Rev Adv Mater Sci 32(2):133–148

Kang LM, Yang C (2019) A review on high-strength titanium alloys: microstructure, strengthening, and properties. Adv Eng Mater 1801359:1–27

Gomez-Gallegos A, Mandal P, Gonzalez D, Zuelli N, Blackwell P (2018) Studies on titanium alloys for aerospace application. Superplasticity in Advanced Materials, ICSAM 385:419–423

Boyer RR (1995) Titanium for aerospace: rationale and applications. Adv Perform Mater 2(4):349–368

Putyrskii SV, Yakovlev AL, Nochovnaya NA (2018) Benefits and applications of high-strength titanium alloys. Russ Eng Res 38(12):945–948

Koizumi H, Takeuchi Y, Imai H, Kawai T, Yoneyama T (2019) Application of titanium and titanium alloys to fixed dental prostheses. J Prosthodont Res 63(3):266–270

Elias CN, Lima JHC, Valiev R, Meyers MA (2008) Biomedical applications of titanium and its alloys. Biol Mater Sci 60(3):46–49

Ai J, Li M, Qin H, Dou S, Huang W (2008) Fatigue failure analysis of XX type helicopter main rotor hub Ti023 central components. Helicopter technique 156(4):33–36

Huang W, Yu J, Zhang X, Dou S, Li M (2010) Failure analysis and manufacturing technology for titanium central component of helicopter rotor hub. Aeronaut Manuf Technol 20:68–72

Bao J, Xu E (1981) Polishing of TC4 titanium alloy blade. Aeronaut Manuf Technol 11:7–9

Xu S (2014) Measures to solve the ablation problem of titanium alloy blade in aeroengine during polishing. China New Technol Prod 3:105–106

Cui W, Li X, Su G, Hu C (2017) Experiment on surface integrity of polishing for titanium TB6. Aeronaut Manuf Technol 4:73–78

Chen Y, Cui W, Li X, Chen Z, Li X (2015) Experiment of rubber wheel CNC polishing for superalloy and titanium alloy. Aeronaut Manuf Technol S2:146–149

Miao M (2016) Research on surface roughness and surface topography of titanium alloy in polishing. Machine Tool and Hydraulics 44(15):122–125

Tian M (2015) Influence of polishing parameters on surface metamorphic layer in polishing titanium alloy. Tool Eng 49(11):71–74

Xiao G, Huang Y (2017) Experimental research and modelling of life-cycle material removal in belt finishing for titanium alloy. J Manuf Process 30:255–267

Axinte DA, Kritmanorot M, Axinte M, Gindy NNZ (2005) Investigations on belt polishing of heat-resistant titanium alloys. J Mater Process Technol 166(3):398–404

Chai H, Huang Y, Zhao Y, Zhang XD (2012) Experimental research on the abrasive belt grinding titanium alloy blade of aviation engine. Adv Mater Res 565:64–69

Huang Y, Liu S, Xiao G, He Y, Dai W (2020) Prediction of surface residual stress on titanium alloy generated by belt grinding using molecular system dynamics. Procedia CIRP 87:480–484

Huo W, Xu J, Fu Y (2012) Study on surface integrity of Ti6Al4V alloy by dry grinding with superhard abrasive wheel. J Shandong Univ (Engineering Edition) 42(3):100–104

Xu C, Xu J, Fu YL (2008) Study on abrasive wear of titanium alloy abrasive belt grinding. Aviat Manuf Technol 16:74–76

Luo G, Zou L, Huang Y and Gong M (2020) Study on material removal and surface quality in grinding of titanium alloy with alumina hollow-ball belt. China Mech Eng 31(19):1–11

Yang Y, Zhang Y, Liang Q (2016) Research on application of barrel finishing technology in manufacture of aeroengine. Aeronaut Manuf Technol 11:69–71

Li X, Li W, Wang C, Yang S, Shi H (2018) Surface integrity and anti-fatigue performance of TC4 titanium alloy by mass finishing. China Surf Eng 31(1):15–25

Zhang X, Li X, Li W, Yang S (2014) Numerical simulation analysis of the centrifugal roll finishing of titanium alloy. Surf Technol 43(5):11–15

Wang X, Zhang J (2019) Research on surface tissue and fatigue properties of Ti-6Al-4V titanium alloy under grinding and finishing. Machine Building Automation 4(7):30–32

Yang Q (2006) Experiment studies on polishing titanium alloy blade by vibration. Aviat Precis Manuf Technol 42(3):14–16

Zeng G (2008) Research on process of strengthening and polishing titanium alloy blades. Tool Engineering 42(6):14–17

Zhang J, He S, Yang Q (2019) Research on influence of vibratory finishing on improving surface integrity of TC17 alloy after shot peening. Hot Working Technol 48(24):68–74

Xiao Y, Sun Y, Chen G (2017) Experimental study of magnetic abrasive finishing of TC11 titanium alloy in permanent magnetic field. Surf Technol 46(2):229–234

Guo W, Wu M (2013) Study on magnetic finishing of titanium alloy blisk. Mech Eng Autom 178(3):89–91

Zhao K, Chen H, Li W, Wang H (2014) Experimental study of magnetic abrasive finishing titanium alloy plate. Mach Des Manuf 7:139–141

Tan X, Wang S (2020) Investigating the ability of iron nitride particles to polish titanium plate. Powder Technol 366:653–660

Fan Z, Tian Y, Liu Z, Shi C, Zhao Y (2019) Investigation of a novel finishing tool in magnetic field assisted finishing for titanium alloy Ti-6Al-4V. J Manuf Process 43(7):74–82

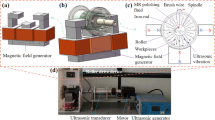

Ma F, Luan S, Luo Q, Liu Y, Sha Z, Zhang S (2019) Effects of ultrasonic assisted magnetic abrasive finishing on surface integrity of titanium alloy. China Surf Eng 32(2):128–136

Ma F, Jiang T, Liu Y, Yang D, Sha Z, Zhang S (2020) Material removal rule and removal function for ultrasonic assisted magnetic abrasive finishing of titanium alloy curved surface. Surf Technol 49(3):290–299

Deng C, Han B, Chen Y (2015) Study of inner surface polishing of titanium alloy elbow pipe by magnetic abrasive finishing. Aeronaut Manuf Technol 3:61–63

Zhang L, Yuan Z, Qi Z, Cai D, Cheng Z, Qi H (2018) CFD-based study of the abrasive flow characteristics within constrained flow passage in polishing of complex titanium alloy surfaces. Powder Technol 333:209–218

Barman A, Das M (2018) Nano-finishing of bio-titanium alloy to generate different surface morphologies by changing magnetorheological polishing fluid compositions. Precis Eng 51:145–152

Liu Z, Sun H, Hou Z, Sang Y, Duan H, Ji G (2020) Experimental study on TC4 titanium alloy by fluid magnetic abrasive finishing. Modern Manuf Eng 1:29–34

Xia Z, Fang F, Ahearne E, Tao M (2020) Advances in polishing of optical freeform surfaces: a review. J Mater Process Technol 286(116828):1–17

Li Z. (2017) Study on mechanism and process of laser polishing of 6H-SiC single crystal and YBCO superconducting thin films. Beijing University of Technology

Perry T, Werschmoeller D, Li X, Pfefferkorn F, Duffie N (2009) Pulsed laser polishing of micro-milled Ti6Al4V samples. J Manuf Process 11(2):74–81

Kumstela J, Kirsch B (2013) Polishing titanium- and nickel-based alloys using cw-laser radiation. Phys Procedia 41:362–371

Jaritngam P, Tangwarodomnukun V, Qi H, Dumkum C (2020) Surface and subsurface characteristics of laser polished ti6al4v titanium alloy. Opt Laser Technol 126(106102):1–12

Trtica M, Gakovic B, Batani D, Desai T, Radak B (2006) Surface modifications of a titanium implant by a picosecond nd:yag laser operating at 1064 and 532nm. Appl Surf Sci 253(5):2551–2556

Yang Q, Wang H, Huang Y, Cheng J, Liu D (2019) Experimental study on nanosecond laser polishing of Ti6Al4V alloy. Optical Technique 45(2):245–250

Bai H, Wang Y, Dong X, Wang B, Liu H, Lu B (2015) Mechanism and size characteristics of microcrack on polished Ti6Al4V. J Xi’an Jiaotong Univ 49(12):117–123

Deng T, Li J, Zheng Z (2019) Fundamental aspects and recent developments of metal surface polishing with energy beam irradiation. Int J Mach Tools Manuf 148(103472):1–26

Gao Y, Lu F, Wang Q (2009) Influence of pulsed electron beam polishing modification on surface morphologies of TC21 titanium alloy. Heat Treat Met 34(5):38–40

Okada A, Uno Y, Yabushita N, Uemura K, Raharjo P (2004) High efficient surface finishing of bio-titanium alloy by large-area electron beam irradiation. J Mater Process Technol 149(1–3):506–511

Okada A, Uno Y, Iio A, Fujiwara K, Doi K (2008) New surface modification method of bio-titanium alloy by eb polishing. J Adv Mech Des Syst Manuf 2(4):694–700

Tokunaga J, Kojima T, Kinuta S, Wakabashi K, Nakamura T, Yatani H, Sohmura T (2009) Large-area electron beam irradiation for surface polishing of cast titanium. Dent Mater J 28(5):571–577

Okada A, Uno Y, Uemura K, Raharjo P, Mcgeough JA (2007) Surface modification for orthopaedic titanium alloy by wide-area electron beam. Proc Inst Mech Eng B J Eng Manuf 221(2):173–178

Allen DM, Shore P, Evans RW, Fanara C, Brien WO, Marson S, Neill WO (2009) Ion beam, focused ion beam, and plasma discharge machining. CIRP Ann Manuf Technol 58(2):647–662

Mayr SG, Ashkenazy Y, Albe K, Averback RS (2003) Mechanisms of radiation-induced viscous flow: role of point defects. Phys Rev Lett 90(5):055505

Dienes GJ, Damask AC (1958) Radiation enhanced diffusion in solids. J Appl Phys 29(12):1713–1721

De Rooij-Lohmann VITA, Kozhevnikov IV, Peverini L et al (2010) Roughness evolution of Si surfaces upon Ar ion erosion. Appl Surf Sci 256(16):5011–5014

Zhou G, Bi Y, Ma Y, Wang L, Wang X, Yu Y, Mutzke A (2019) Large current ion beam polishing and characterization of mechanically finished titanium alloy (Ti6Al4V) surface. Appl Surf Sci 476:905–913

Zhu XP, Lei MK, Ma TC (2003) Surface morphology of titanium irradiated by high-intensity pulsed ion beam. Nucl Instrum Methods Phys Res 211(1):69–79

Teixeira A (2011) Development of an electropolishing method for titanium materials. Concordia University

Bao S, Wu M, Zhang N, Zhang Z (2003) A study of pulse electrochemical polishing technology for titanium alloy. Electromachining and Mould 3:47–50

Md ARK, Rahman MM (2017) Surface finish characteristics of titanium alloy in a non conventional technique. Materials Today: Proceedings 4(9):9352–9355

Yu M, Xu Y, Li S, Yi J, Wu G, Liu J (2009) Environment-friendly electropolishing of titanium alloys. J Univ Sci Technol Beijing 31(1):68–73

Piotrowski O, Madore C, Landolt D (1998) Electropolishing of titanium and titanium alloys in perchlorate-free electrolytes. Plat Surf Finish 85(5):115–119

He C, Tang J, Cheng S, Wang L, Bu Z, Chen M, Geng Y, Sun L (2014) Effect of different electrolyte compositions on the electrolytic plasma polishing of titanium alloy. J Yunnan Normal Univ 34(6):56–61

Balyakin A, Goncharov E, Zhuchenko E (2019) The effect of preprocessing on surface quality in the chemical polishing of parts from titanium alloy produced by SLM. Materials Today: Proceedings 19:2291–2294

Wang L, Jiang X, Liu H, Huang N (2012) Study on chemical polishing technics of titanium alloy (TC4). Materials Reports 26(20):364–391

Bao S, Wu M, Liu Z (2005) Electrochemical polishing for biomedical titanium alloy (T i–6Al-4V) implants with action of ultrasonic waves. Surf Technol 34(6):25–27

Uchida T, Kikuchi T, Setoyama Y, Kawashima N, Takeuchi S (2006) Improvement of dispersion of nanometer-sized diamond particles for precise polishing by ultrasound exposure. J Acoust Soc Am 120(5):3369

Liao M, Han B, Chen Y, Yu Z (2016) Inner surface of titanium alloy tube by electrochemical magnetic abrasive compound finishing. China Surf Eng 29(3):123–131

Tian T, Chen Y, Tan Y, Liu Y (2017) Optimization of process parameters for electrolytic magnetic abrasive grinding of titanium alloy. Plating and Finishing 40(1):27–30

Ozdemir Z, Ozdemir A, Basim GB (2016) Application of chemical mechanical polishing process on titanium based implants. Mater Sci Eng C 68:383–396

Liang C, Liu W, Li S, Kong H, Zhang Z, Song Z (2016) A nano-scale mirror-like surface of Ti-6Al-4V attained by chemical mechanical polishing. Chinese Physics B 25(5):058301

Zhang Z, Shi Z, Du Y, Yu Z, Guo L, Guo D (2018) A novel approach of chemical mechanical polishing for a titanium alloy using an environment-friendly slurry. Appl Surf Sci 427:409–415

Zou L, Li H, Yang Y, Huang Y (2020) Feasibility study of minimum quantity lubrication assisted belt grinding of titanium alloys. Mater Manuf Process 35(9):961–968

Funding

This work was supported by the National Natural Science Foundation of China (NSFC) under Grant Nos. 51905356 and 52005351, Doctoral Start-up Foundation of Liaoning Province under Grant No. 2020-BS-178, and Open Fund of Key Laboratory of Fundamental Science for National Defense of Aeronautical Digital Manufacturing Process of Shenyang Aerospace University under Grant No. SHSYS202002.

Author information

Authors and Affiliations

Contributions

The authors discussed each reference paper together and contributed useful ideas for this manuscript.

Corresponding authors

Ethics declarations

Consent to participate

The authors consent to participate.

Consent for publication

Yes.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hou, N., Wang, M., Wang, B. et al. Fundamental functions of physical and chemical principles in the polishing of titanium alloys: mechanisms and problems. Int J Adv Manuf Technol 118, 2079–2097 (2022). https://doi.org/10.1007/s00170-021-08100-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-08100-4