Abstract

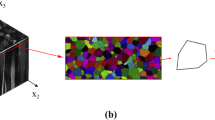

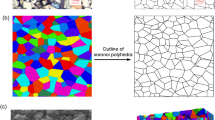

The finite-discrete element method (FDEM) can be used to simulate brittle materials such as polycrystalline ice with specific geometric information. However, most previous studies treat ice as intact and nonporous, ignoring the effect of internal porosity. In this study, an FDEM model of polycrystalline ice with specific porosity is built by using the cohesive interface element and the method of randomly deleting elements. Comparison with experimental results confirms that the model can capture the strength properties and deformation patterns of polycrystalline ice. The fracture failure patterns and mechanical responses of ice specimens and their relationships with porosity are investigated by uniaxial compression tests and Brazilian splitting tests. The results show that with increasing porosity, the fracture failure patterns of the specimens in the uniaxial compression test evolve into three types: global shear failure, local shear failure and local tensile‒shear failure. There is no obvious difference in the failure patterns of the specimens in the Brazilian splitting test. In addition, as the porosity increases, the material exhibits a transition from brittleness to ductility, and the porosity also affects the local fragmentation characteristics inside the polycrystalline ice, significantly weakening the strength of the specimens.

Graphic Abstract

Similar content being viewed by others

References

Kääb, A., Jacquemart, M., Gilbert, A., et al.: Sudden large-volume detachments of low-angle mountain glaciers–more frequent than thought? Cryosphere 15(4), 1751–1785 (2021). https://doi.org/10.5194/tc-15-1751-2021

Kääb, A., Leinss, S., Gilbert, A., et al.: Massive collapse of two glaciers in western Tibet in 2016 after surge-like instability. Nat. Geosci. 11(2), 114–120 (2018). https://doi.org/10.1038/s41561-017-0039-7

Tian, L., Yao, T., Gao, Y., et al.: Two glaciers collapse in western Tibet. J. Glaciol. 63(237), 194–197 (2017). https://doi.org/10.1017/jog.2016.122

Wang, W., Yang, J., Wang, Y.: Dynamic processes of 2018 Sedongpu landslide in Namcha Barwa-Gyala Peri massif revealed by broadband seismic records. Landslides 17(2), 409–418 (2020). https://doi.org/10.1007/s10346-019-01315-3

Shugar, D., Jacquemart, M., Shean, D., et al.: A massive rock and ice avalanche caused the 2021 disaster at Chamoli, Indian Himalaya. Science 373(6552), 300–306 (2021). https://doi.org/10.1126/science.abh4455

Åström, J.A., Vallot, D., Schäfer, M., et al.: Termini of calving glaciers as self-organized critical systems. Nat. Geosci. 7(12), 874–878 (2014). https://doi.org/10.1038/ngeo2290

Mellor, M., Cole, D.M.: Stress/strain/time relations for ice under uniaxial compression. Cold Reg. Sci. Technol. 6(3), 207–230 (1983). https://doi.org/10.1016/0165-232X(83)90043-5

Jones, S.J.: High strain-rate compression tests on ice. J. Phys. Chem. B 101(32), 6099–6101 (1997). https://doi.org/10.1021/jp963162j

Hawkes, I., Mellor, M.: Deformation and fracture of ice under uniaxial stress. J. Glaciol. 11(61), 103–131 (1972). https://doi.org/10.3189/S002214300002253X

Cole, D.M.: Strain-rate and grain-size effects in ice. J. Glaciol. 33(115), 274–280 (1987). https://doi.org/10.3189/S0022143000008844

Schulson, E.M.: The brittle compressive fracture of ice. Acta Metall. Mater. 38(10), 1963–1976 (1990). https://doi.org/10.1016/0956-7151(90)90308-4

Wang, B., Yang, W., Sun, P., et al.: Experimental study on the influence of freezing pressure on the uniaxial mechanical properties of ice. Adv. Civ. Eng. (2021). https://doi.org/10.1155/2021/8651467

Jones, S.J., Chew, H.A.M.: Effect of sample and grain size on the compressive strength of ice. Ann. Glaciol. 4, 129–132 (1983). https://doi.org/10.3189/S0260305500005358

Jones, S.J., Gagnon, R., Derradji, A., et al.: Compressive strength of iceberg ice. Can. J. Phys. 81(1–2), 191–200 (2003). https://doi.org/10.1139/p02-137

Kuehn, G.A., Schulson, E.M., Jones, D.E., et al.: The compressive strength of ice cubes of different sizes. ASME. J. Offsh. Mech. Arct. Eng. 115(2), 142–148 (1993). https://doi.org/10.1115/1.2920104

Batto, R.A., Schulson, E.M.: On the ductile-to-brittle transition in ice under compression. Acta Metall. Mater. 41(7), 2219–2225 (1993). https://doi.org/10.1016/0956-7151(93)90391-5

Kuehn, G.A., Schulson, E.M.: The mechanical properties of saline ice under uniaxial compression. Ann. Glaciol. 19, 39–48 (1994). https://doi.org/10.3189/1994AoG19-1-39-48

Rist, M.A., Murrell, S.A.F.: Ice triaxial deformation and fracture. J. Glaciol. 40(135), 305–318 (1994). https://doi.org/10.3189/S0022143000007395

Gagnon, R.E., Gammon, P.H.: Triaxial experiments on iceberg and glacier ice. J. Glaciol. 41(139), 528–540 (1995). https://doi.org/10.3189/S0022143000034869

Arakawa, M., Maeno, N.: Mechanical strength of polycrystalline ice under uniaxial compression. Cold. Reg. Sci. Technol. 26(3), 215–229 (1997). https://doi.org/10.1016/S0165-232X(97)00018-9

Stone, B.M., Jordaan, I.J., Xiao, J., et al.: Experiments on the damage process in ice under compressive states of stress. J. Glaciol. 43(143), 11–25 (1997). https://doi.org/10.3189/S002214300000277X

Berenbaum, R., Brodie, I.: Measurement of the tensile strength of brittle materials. Br. J. Appl. Phys. 10(6), 281 (1959). https://doi.org/10.1088/0508-3443/10/6/307

Litwin, K.L., Zygielbaum, B.R., Polito, P.J., et al.: Influence of temperature, composition, and grain size on the tensile failure of water ice: implications for erosion on Titan. J. Geophys. Res.-Planet. 117, E08013 (2012). https://doi.org/10.1029/2012JE004101

Deng, Y., Li, Z., Li, Z., et al.: The experiment of fracture mechanics characteristics of Yellow River Ice. Cold. Reg. Sci. Technol. 168, 102–896 (2019). https://doi.org/10.1016/j.coldregions.2019.102896

Brogliato, B., Ten Dam, A., Paoli, L., et al.: Numerical simulation of finite dimensional multibody nonsmooth mechanical systems. Appl. Mech. Rev. 55(2), 107–150 (2002). https://doi.org/10.1115/1.1454112

Nie, J., Cui, Y.F., Senetakis, K., et al.: Predicting residual friction angle of lunar regolith based on Chang’e-5 lunar samples. Sci. Bull. 68(7), 730–739 (2023). https://doi.org/10.1016/j.scib.2023.03.019

Rappaz, M., Bellet, M., Deville, M.O., et al.: Numerical modeling in materials science and engineering. Springer, Berlin (2003)

Zhang, S., El Kerdi, O., Khurram, R.A., et al.: FEM analysis of in-flight ice break-up. Finite. Elem. Anal. Des. 57, 55–66 (2012). https://doi.org/10.1016/j.finel.2012.03.005

Plate, C., Müller, R., Humbert, A., et al.: Evaluation of the criticality of cracks in ice shelves using finite element simulations. Cryosphere 6(5), 973–984 (2012). https://doi.org/10.5194/tc-6-973-2012

Qiu, W., Peng, R.: Research on the numerical simulation for plastic model of ice as building materials under triaxial compression. Const.r Build Mater. 268, 121–183 (2021). https://doi.org/10.1016/j.conbuildmat.2020.121183

Cundall, P.A., Strack, O.D.L.: A discrete numerical-model for granular assemblies. Géotechnique 29(1), 47–65 (1979). https://doi.org/10.1680/geot.1979.29.1.47

Long, X., Ji, S., Wang, Y.: Validation of microparameters in discrete element modeling of sea ice failure process. Particul. Sci. Technol. 37(5), 550–559 (2019). https://doi.org/10.1080/02726351.2017.1404515

Di, S., Xue, Y., Bai, X., et al.: Effects of model size and particle size on the response of sea-ice samples created with a hexagonal-close-packing pattern in discrete-element method simulations. Particuology 36, 106–113 (2018). https://doi.org/10.1016/j.partic.2017.04.004

Bassis, J.N., Jacobs, S.: Diverse calving patterns linked to glacier geometry. Nat. Geosci. 6(10), 833–836 (2013). https://doi.org/10.1038/ngeo1887

Van Dongen, E.C.H., Åström, J.A., Jouvet, G., et al.: Numerical modeling shows increased fracturing due to melt-undercutting prior to major calving at Bowdoin Glacier. Front. Earth. Sci. 8, 253 (2020). https://doi.org/10.3389/feart.2020.00253

Åström, J.A., Riikilä, T.I., Tallinen, T., et al.: A particle based simulation model for glacier dynamics. Cryosphere 7(5), 1591–1602 (2013). https://doi.org/10.5194/tc-7-1591-2013

Munjiza, A.: The Combined Finite-Discrete Element Method. Wiley, New York (2004)

Munjiza, A., Xiang, J., Garcia, X., et al.: The virtual geoscience workbench, VGW: Open source tools for discontinuous systems. Particuology. 8(2), 100–105 (2010). https://doi.org/10.1016/j.partic.2009.04.008

Tatone, B.S.A., Grasselli, G.: A calibration procedure for two-dimensional laboratory-scale hybrid finite–discrete element simulations. Int. J. Rock. Mech. Min. 75, 56–72 (2015). https://doi.org/10.1016/j.ijrmms.2015.01.011

Liu, Q., Deng, P.: A numerical investigation of element size and loading/unloading rate for intact rock in laboratory-scale and field-scale based on the combined finite-discrete element method. Eng. Fract. Mech. 211, 442–462 (2019). https://doi.org/10.1016/j.engfracmech.2019.02.007

Zhou, B., Ku, Q., Li, C., et al.: Single-particle crushing behaviour of carbonate sands studied by X-ray microtomography and a combined finite–discrete element method. Acta. Geotech. 17, 3195–3209 (2022). https://doi.org/10.1007/s11440-022-01469-w

Fukuda, D., Liu, H., Zhang, Q., et al.: Modelling of dynamic rock fracture process using the finite-discrete element method with a novel and efficient contact activation scheme. Int. J. Rock. Mech. Min. 138, 104–645 (2021). https://doi.org/10.1016/j.ijrmms.2021.104645

Gribanov, I., Taylor, R., Sarracino, R.: Cohesive zone micromechanical model for compressive and tensile failure of polycrystalline ice. Eng. Fract. Mech. 196, 142–156 (2018). https://doi.org/10.1016/j.engfracmech.2018.04.023

Kronenberg, M., Machguth, H., Eichler, A., et al.: Comparison of historical and recent accumulation rates on Abramov Glacier, Pamir Alay. J. Glaciol. 67(262), 253–268 (2021). https://doi.org/10.1017/jog.2020.103

Quey, R., Dawson, P., Barbe, F.: Large-scale 3D random polycrystals for the finite element method: generation, meshing and remeshing. Comput. Method. Appl. M. 200(17–20), 1729–1745 (2011). https://doi.org/10.1016/j.cma.2011.01.002

Ma, G., Zhou, W., Regueiro, R.A., et al.: Modeling the fragmentation of rock grains using computed tomography and combined FDEM. Powder Technol. 308, 388–397 (2017). https://doi.org/10.1016/j.powtec.2016.11.046

Wu, Z., Ji, X., Liu, Q., et al.: Study of microstructure effect on the nonlinear mechanical behavior and failure process of rock using an image-based-FDEM model. Comput. Geotech. 121, 103480 (2020). https://doi.org/10.1016/j.compgeo.2020.103480

Lisjak, A., Tatone, B.S.A., Grasselli, G., et al.: Numerical modelling of the anisotropic mechanical behaviour of Opalinus Clay at the laboratory-scale using FEM/DEM. Rock. Mech. Rock. Eng. 47, 187–206 (2014). https://doi.org/10.1007/s00603-012-0354-7

Kuutti, J., Kolari, K., Marjavaara, P.: Simulation of ice crushing experiments with cohesive surface methodology. Cold. Reg. Sci. Technol. 92, 17–28 (2013). https://doi.org/10.1016/j.coldregions.2013.03.008

Lilja, V.P., Polojärvi, A., Tuhkuri, J., et al.: Finite-discrete element modelling of sea ice sheet fracture. Int. J. Solids Struct. 217, 228–258 (2021). https://doi.org/10.1016/j.ijsolstr.2020.11.028

Liu, L., Ji, S.: Bond and fracture model in dilated polyhedral DEM and its application to simulate breakage of brittle materials. Granul. Matter. 21, 41 (2019). https://doi.org/10.1007/s10035-019-0896-4

Wei, D., Zhao, B., Dias-da-Costa, D., et al.: An FDEM study of particle breakage under rotational point loading. Eng. Fract. Mech. 212, 221–237 (2019). https://doi.org/10.1016/j.engfracmech.2019.03.036

Zhou, B., Wei, D., Ku, Q., et al.: Study on the effect of particle morphology on single particle breakage using a combined finite-discrete element method. Comput. Geotech. 122, 103532 (2020). https://doi.org/10.1016/j.compgeo.2020.103532

Zhao, B., Wang, J., Coop, M.R., et al.: An investigation of single sand particle fracture using X-ray micro-tomography. Géotechnique 65(8), 625–641 (2015). https://doi.org/10.1680/geot.4.P.157

Lavrov, A., Vervoort, A.: Theoretical treatment of tangential loading effects on the Brazilian test stress distribution. Int. J. Rock. Mech. Min. 39(2), 275–283 (2002). https://doi.org/10.1016/S1365-1609(02)00010-2

Lin, H., Xiong, W., Zhong, W., et al.: Location of the crack initiation points in the Brazilian disc test. Geotech. Geol. Eng. 32(5), 1339–1345 (2014). https://doi.org/10.1007/s10706-014-9800-5

Acknowledgements

This study was financially supported by the Second Tibetan Plateau Scientific Expedition and Research Program (STEP) (Grant No. 2019QZKK0906) and the National Natural Science Foundation of China (Grant Nos. 41941017, U21A2008, U20A20112).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, Y., Tang, J. & Yan, S. Fracture failure characteristics of porous polycrystalline ice based on the FDEM. Granular Matter 25, 50 (2023). https://doi.org/10.1007/s10035-023-01350-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10035-023-01350-x