My Goal: Configure a Pelican 1510 to secure my CSM and also contain a sturdy but lightweight table.

JULY 6: Inspired by the idea to have a lighter CSM travel with table option, today my boyfriend and I are overnighting in Bellingham, Wa to pickup a Harbor Freight inexpensive and light but sturdy table.

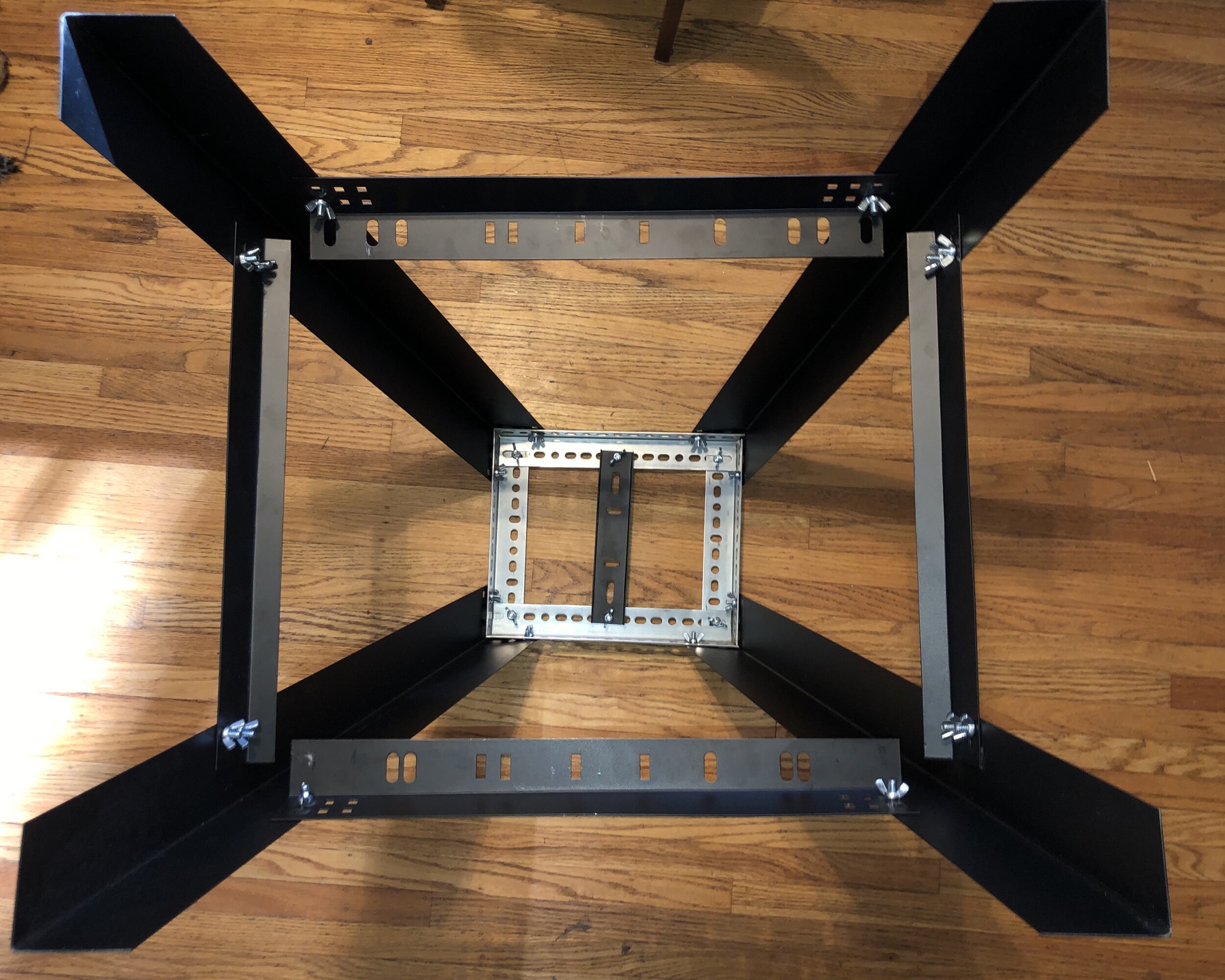

Photos of the modifications and timeline steps

I never seem to have one thing on the go so forgive me for jumping around.

Ok back at it - I am in lust with the idea of having a table which can be assembled and stored in a secure case also holding my machine. Having this for car travel events would be ideal but being so would allow for future airplane travel event destinations as well.

REGARDING FOAM

Foam is NOT CHEAP - but if you purchase non-pluck (non-pre-cut into cubes) foam it should last with extensive wear and tear if you protect the foam from oil contact.

The only person who really spoke about foam when I was seeking info suggested 1” thick layers purchased by the Foam Mattress shop - after having done this I realized that perhaps I’d prefer some thicker layers than what I’d ordered. Darn. Using foam one has to decide how to best align the parts within the case in a 3D layout. One has to decide whether to glue layers together or to leave the multiple foam layers like a puzzle. I would strongly caution against an extensive and confusing series of foam layers as this makes putting all back inside more difficult if flying - the harder it is for airport staff to return items the less likely they will be returned safely to the case - I’ve heard stories. :(

REGARDING CASES

A couple months ago I found a great deal for a larger 1650 Pelican online so I bought it (then upgraded the latches and wheels), and then I ordered two styles of special foam for it from a foam mattress shop. I didn’t finish customizing the foam to the case as I wanted to keep my options open (room for a second machine sometime in the future?!)

Ok so about the brand of cases I have and want to plan this for….

(I went with these because I was wrongly told this case will 100% cover the contents if something should happen when using the case and flying)

**Before we go any further I have had confirmation from Pelican itself that their guarantee ONLY covers the cost of the case - not the contents - so be SURE not to over pack a smaller case with too much weight!

**One can easily purchase a similar, secure case from a store like Harbor Freight at a much lower cost**

PELICAN CASES (more info on this website)

The Pelican 1510 Interior dimensions (LxWxD) 19.75"x11"x7.60" (50.2 x 27.9 x 19.3 cm)

The Pelican 1650 Interior dimensions (LxWxD) 28.57"x17.52"x10.65" (72.6 x 44.5 x 27.1 cm)

Looking at costs the new Pelican case 1510 was quoted at CAD$207.

REGARDING TABLES

The table I was using that the time - the popular adjustable height Ridgid table frame ‘travel table’, has a very wide table frame that can’t be reduced in size. See BLOG ENTRY ON THESE TABLES HERE. When in stock this table frame, a “Ridgid Flip Top Portable Work Support Stand” can be purchase from many sources including Home Depot, Amazon and eBay.

Ridgid table frame dimensions: (Height x Width x Depth) 7.50” x 21.70” x 30.60’. Weighs 24.29lbs (as per Home Depot).

So then I broke down what I wanted and how I could make this happen.

I noted that the wonderful Lamb Tuttle (correctly referred to as the Lamb LT-150 which is bundled with a beautiful reinforced metal table). Sadly the table alone was outside of my budget, quoted at $410 USD (plus shipping/customs).

I also noted that the build for a table like this doesn’t appear difficult so I gave thought to making one perhaps completely from hardware supplies. Unfortunately for the cost for one metal leg I could instead buy a similar mostly finished similar design table from Harbor Freight in the States - they don’t have Canada shipping. Weekend adventuring yay! From home to the store it’s slightly over a 2 hour round trip drive if done in one visit. Harbor Freight sells this table for USD$35 with an additional 20% off coupon.

While planning our trip I continued to do my homework - I fell in love with the (Universal CSM Table) “NZAK Multi Machine Stand” offered by Jacquie Grant of Sock World however it lists at $349 CAD (plus shipping/customs). It is VERY lightweight. I need to win the lottery.

Ok back to the idea of the Harbor Freight table - the idea of a metal, easy-to-assemble style of table has been bouncing around in my head for a couple months.

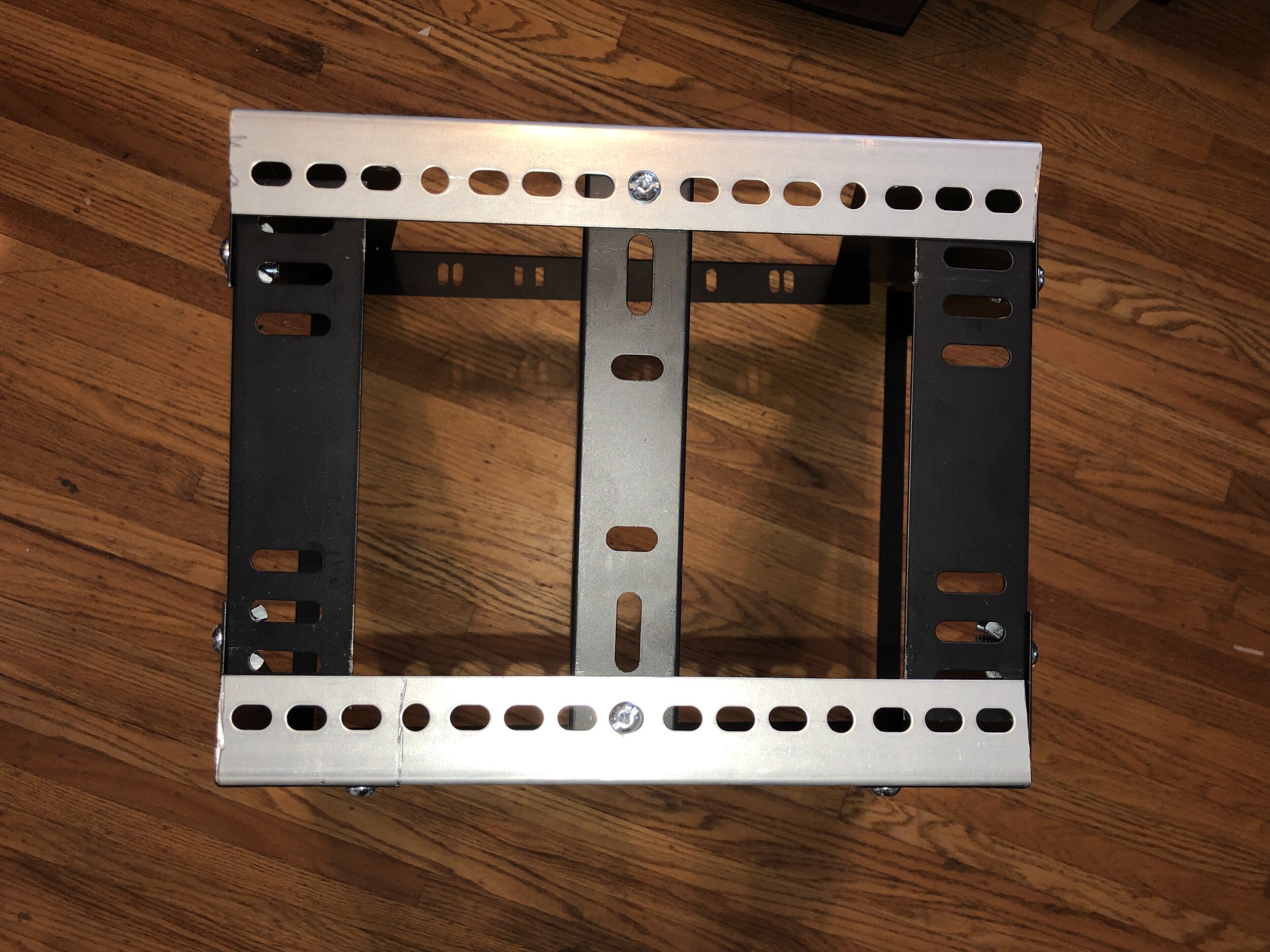

Alas I discovered the American retail store “Harbor Freight”. They are a tool focused multi-location shop that does not ship to Canada. However after viewing their “29’ Heavy Duty Tool Stand” for USD$34.99 my boyfriend and I decided to make a romantic overnight trip on the weekend. When we drove the 2.5 hours to get to the nearest location (Bellingham, Washington), they had one on display and one unopened package on the shelf. (We had called ahead - they’d said they had 5 in stock). Their website even offered a 20% off coupon shown at the cashier. SCORE!

FANTASTIC!

We even picked up a totally useful Folding Platform Truck for USD#39.99

We had such a lovely time in Washington - I had my first Olive Garden visit - we walked around a near a large park with nature trails - we shopped at Trader Joes - AND we went to Bellisfair mall where we discovered a store called TORRID. We got my honey a new pair of kicking runners and three wonderful dress shirts at JC Penny.

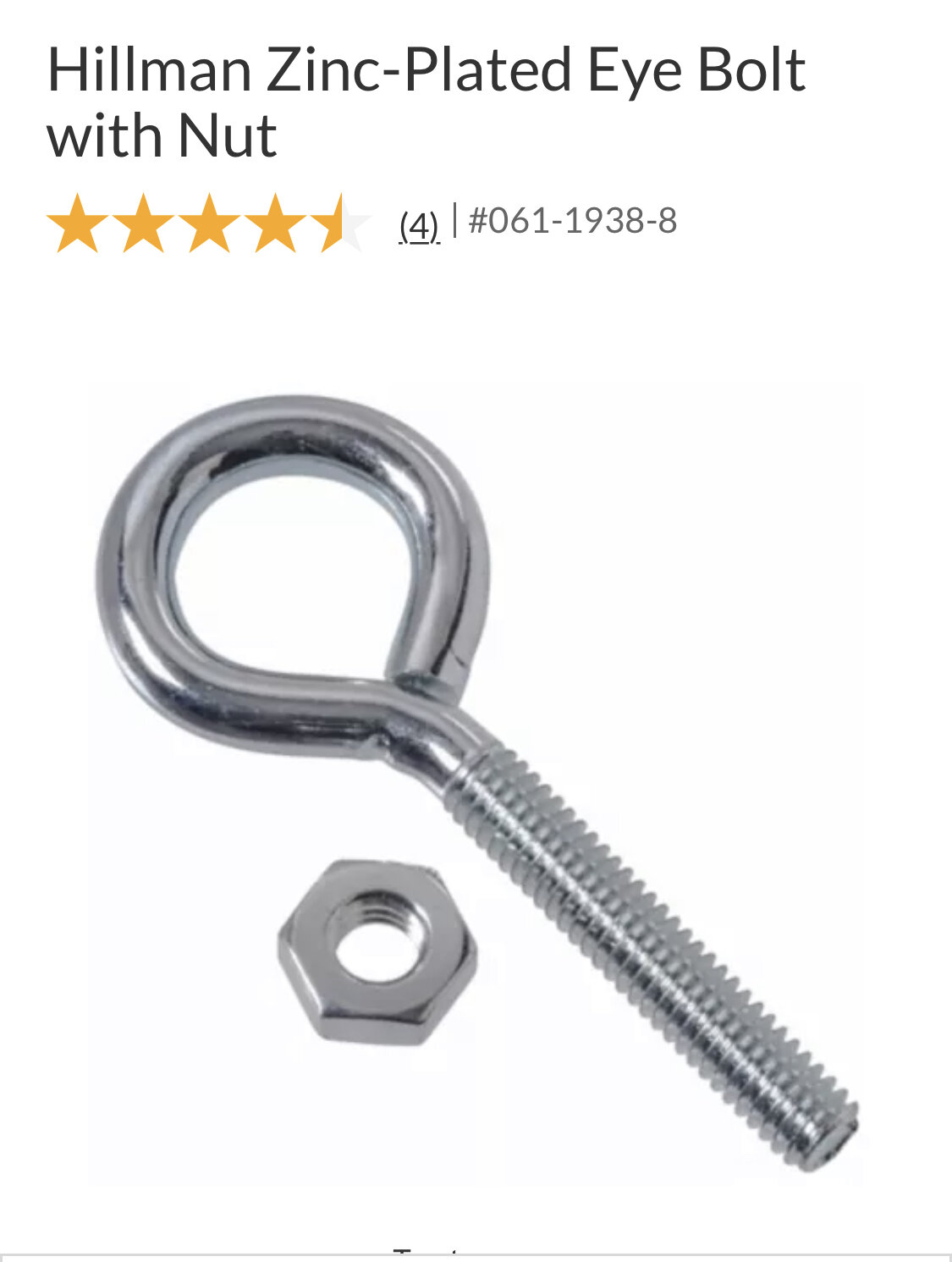

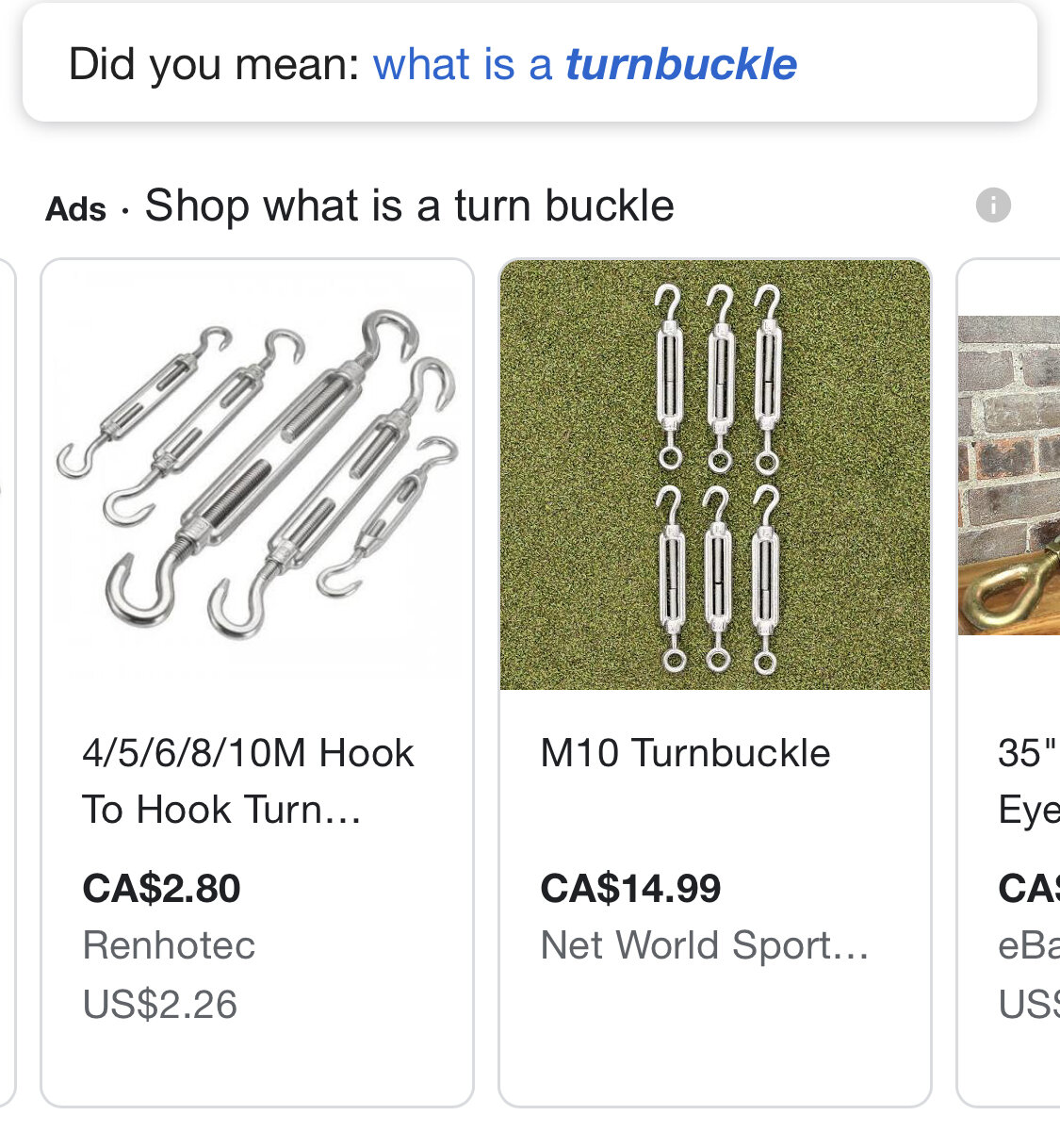

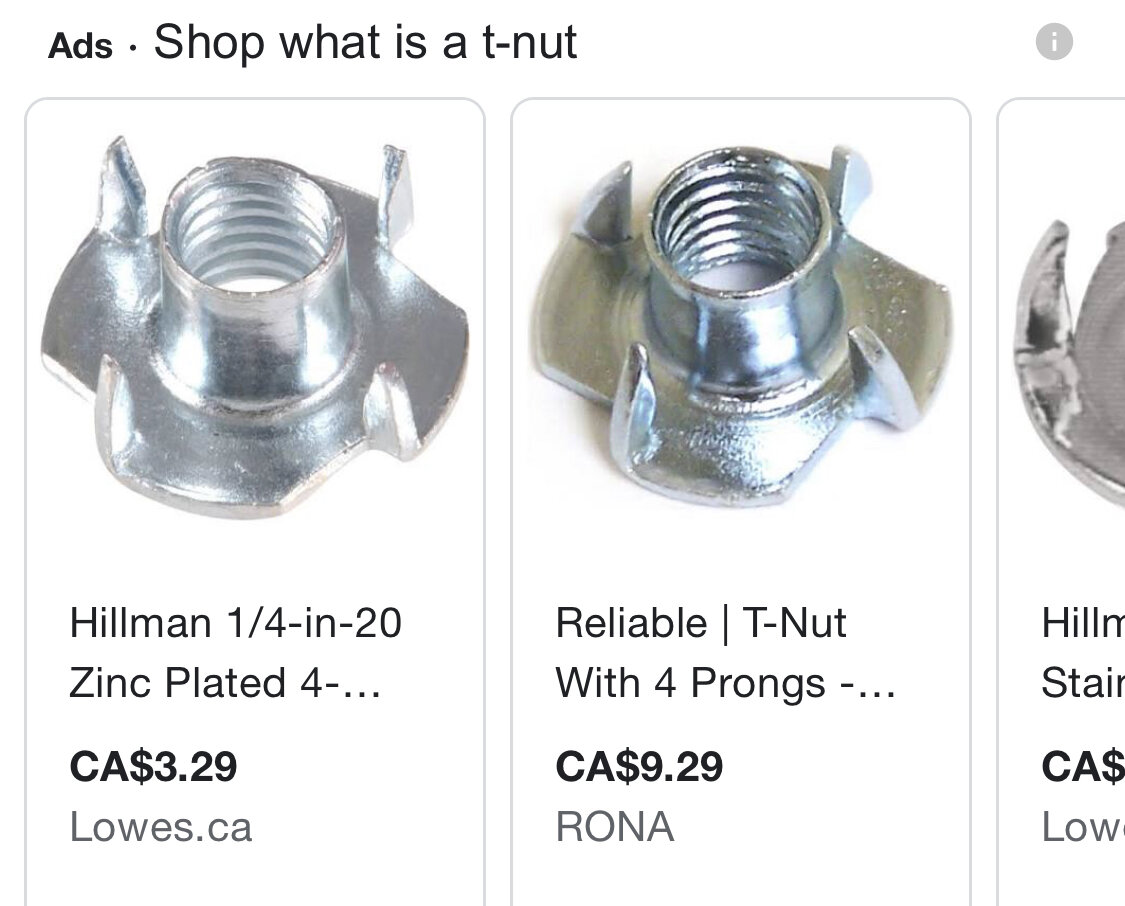

Once we were back on home soil we stopped at home depot again and upgraded from the imperial screws used to metric to be able to also use wingnuts instead of the regular connectors that came with the table.

I am now eagerly awaiting the Pelican 1510 case that I ordered.

FOLLOW-UP: The table is complete and as amazing as hoped.With the wooden top I found the table to weigh 15-20lbs - sadly more than hoped. Assembling this table takes approximately 20 minutes however considering all I am still very pleased.

Also on INSTAGRAM - REF1,