Enterprise Asset Management (EAM)

EAM is a recent addition to the Information Technology lexicon in organizations where hardware and software maintenance activities must be closely coordinated with managing enterprise-wide systems. These systems include Enterprise Resource Planning (ERP), Product Data Management (PDM), Customer Relationship Management (CRM), and other enterprise application integration (EAI) platforms.

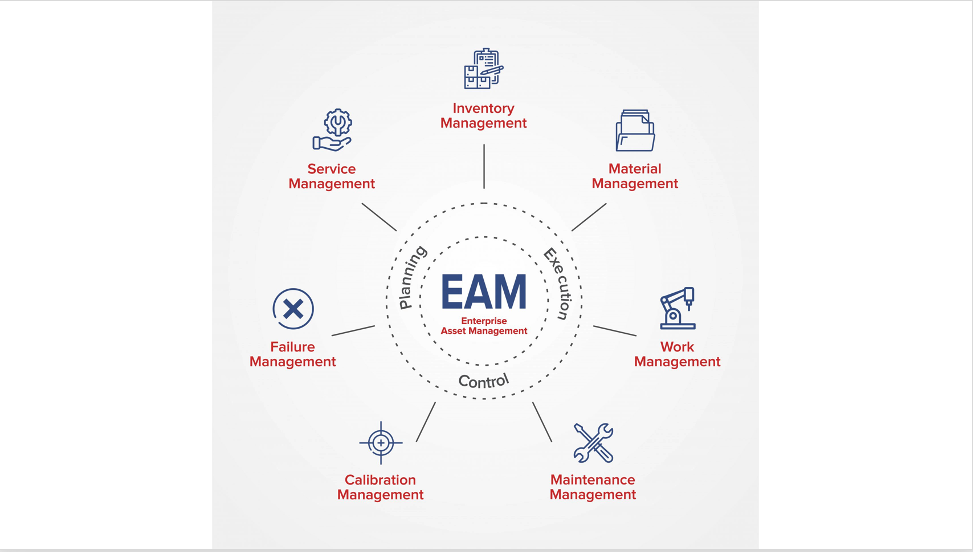

The EAM framework focuses on the operational maintenance aspects of enterprise systems rather than on individual desktops or point solutions found in a typical asset inventory system. This emphasis on maintenance has its roots in the ERP system paradigm. ERP creates “value” from the underlying assets by managing the “value producing” processes in a structured and predictable manner. EAM does the same for the physical software and hardware assets that enable ERP.

EAM Requirements

Industries that depend on strategic assets face similar management problems:

- Work management.

- Compliance with regulatory, safety, corporate policy; union rules; and normative industry guidelines.

- Resource allocation, utilization, constraint management, and budgeting processes.

The management of these processes can be facilitated in many ways. It has been shown that the biggest time waster is the preparation of the maintenance process. Simple things like gathering documentation, planning outage times, coordinating with the user community, and arranging the software and hardware maintenance processes.

In many industries, any disruption to an operational enterprise system means unnecessary cost burdens on the direct business unit. Planning and adherence to the plan are critical success factors for any asset management organization.

To provide these management activities seamlessly, an EAM system must be capable of the following:

- Work management – through tools that provide process control for maintenance activities. This includes the interpretation and fulfillment of maintenance requests.

- Inventory management – through tools that provide stock planning, version control, stakeholder communication, and the automatic electronic management of all assets.

- Knowledge management – capturing the best work practices from previous activities, storing and disseminating this knowledge promptly and accurately.

- Resource management – can only be effective if the right information is available at the right time to the right resources.

For success, the EAM systems must provide this framework for all applications across the enterprise. Such solutions must operate in ways similar to ERP. Data is entered once and used many times, workflow processes are coordinated across distributed business units, and business rules and constraints are applied to these work processes.