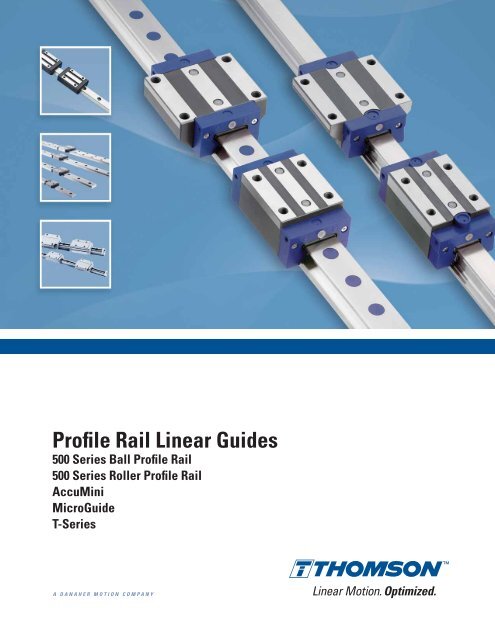

Profile Rail Linear Guides

Profile Rail Linear Guides

Profile Rail Linear Guides

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Profile</strong> <strong>Rail</strong> <strong>Linear</strong> <strong>Guides</strong><br />

500 Series Ball <strong>Profile</strong> <strong>Rail</strong><br />

500 Series Roller <strong>Profile</strong> <strong>Rail</strong><br />

AccuMini<br />

MicroGuide<br />

T-Series<br />

A DANAHER MOTION COMPANY<br />

<strong>Linear</strong> Motion. Optimized.

Thomson -<br />

<strong>Linear</strong> Motion. Optimized.<br />

<strong>Linear</strong> Motion. Optimized.<br />

Often the ideal design solution is not about finding the fastest, sturdiest, most accurate or even the least expensive option.<br />

Rather, the ideal solution is the optimal balance of performance, life and cost.<br />

Thomson is best positioned to help you most quickly configure the optimal linear motion solution for your application.<br />

• Thomson invented anti-friction linear bearing technology. We own the broadest standard product offering of mechanical<br />

motion technologies in the industry.<br />

• Modified versions of standard product are routine. White sheet design solutions available across our entire portfolio.<br />

• Choose Thomson and gain access to over 70 years of global application experience in diverse industries including<br />

packaging, factory automation, material handling, medical, clean energy, printing, automotive, machine tool, aerospace<br />

and defense.<br />

• As part of Danaher Motion, we are financially strong and unique in our ability to bring together control, drive, motor,<br />

power transmission and precision linear motion technologies.<br />

Thomson is the name you can trust for quality, innovation, on-time delivery, controlled costs, and<br />

reduced risk.<br />

In addition to the information contained in this document, a wealth of product and application information is available online<br />

at www.thomsonlinear.com. Also online are downloadable 3D models, software tools, our distributor locator and global<br />

contact information for Thomson. For immediate assistance in North America contact us at 1-540-633-3549 or email us at<br />

Thomson@danahermotion.com.<br />

Talk to us early in the design process to see how Thomson can help identify the optimal balance of performance, life and<br />

cost for your next application. And, call us or any of our 2000+ distribution partners around the world for fast delivery of<br />

replacement parts.<br />

The Danaher Business System -<br />

Building sustainable competitive advantage into your business<br />

The Danaher Business System (DBS) was established to increase the value we bring to customers. It is a mature and successful<br />

set of tools we use daily to continually improve manufacturing operations and product development processes. DBS is based<br />

on the principles of Kaizen which continuously and aggressively eliminate waste in every aspect of our business. DBS<br />

focuses the entire organization on achieving breakthrough results that create competitive advantages in quality, delivery and<br />

performance – advantages that are passed on to you. Through these advantages Thomson is able to provide you faster times<br />

to market as well as unsurpassed product selection, service, reliability and productivity.<br />

Local Support Around the Globe<br />

Application Centers Global Manufacturing Operations Global Design & Engineering Centers<br />

Application Centers<br />

Global Manufacturing Operations<br />

Global Design & Engineering Centers

An Overview of Danaher Motion – Thomson <strong>Profile</strong> <strong>Rail</strong><br />

<strong>Profile</strong> <strong>Rail</strong> <strong>Linear</strong> <strong>Guides</strong><br />

500 Series Ball<br />

<strong>Profile</strong> <strong>Rail</strong><br />

Overview ...................................................................................................................... 4<br />

500 Series Ball <strong>Profile</strong> <strong>Rail</strong> <strong>Linear</strong> Guide .............................................................. 8<br />

Thomson Next Generation <strong>Profile</strong> <strong>Rail</strong>. Superior Design. Superior Quality.<br />

Product overview ................................................................................................. 9<br />

Part numbering ................................................................................................... 19<br />

Datasheets .......................................................................................................... 21<br />

Options and accessories .................................................................................. 31<br />

Accuracy information ....................................................................................... 42<br />

Preload information ........................................................................................... 42<br />

500 Series Roller <strong>Profile</strong> <strong>Rail</strong> <strong>Linear</strong> Guide ........................................................ 44<br />

Thomson Next Generation <strong>Profile</strong> <strong>Rail</strong>. Superior Design. Superior Quality.<br />

Product overview ............................................................................................... 45<br />

Part numbering ................................................................................................... 53<br />

Datasheets .......................................................................................................... 55<br />

Options and accessories .................................................................................. 59<br />

Lubrication Fittings ............................................................................................ 70<br />

Accuracy information ....................................................................................... 71<br />

Preload information ........................................................................................... 71<br />

AccuMini.................................................................................................................... 73<br />

Ultra Compact, High Roll & Superior, Patented Ball Control Design.<br />

Product overview ............................................................................................... 73<br />

Part numbering ................................................................................................... 73<br />

Datasheets .......................................................................................................... 74<br />

Accuracy information ....................................................................................... 76<br />

Preload information ........................................................................................... 76<br />

MicroGuide ................................................................................................................ 77<br />

T-Series ....................................................................................................................... 84<br />

Installation Guide ..................................................................................................... 92<br />

Engineering Guide .................................................................................................... 96<br />

Sizing, selection and life load calculations ................................................... 97<br />

Deflection .......................................................................................................... 104<br />

Lubrication ........................................................................................................ 126<br />

Bellow cover calculations ............................................................................. 128<br />

Butt joint specification sheets ....................................................................... 129<br />

Conversion factors .......................................................................................... 132<br />

Interchange Guide .................................................................................................. 134<br />

For more information, or to place an order, please contact your local authorized<br />

Thomson distributor or Danaher Motion at 1-540-633-3400, Fax: 1-540-633-4162,<br />

or E-mail at profilerail@danahermotion.com.<br />

500 Series Roller<br />

<strong>Profile</strong> <strong>Rail</strong> AccuMini<br />

MicroGuide T-Series<br />

Lubrication<br />

Fittings<br />

Installation<br />

Guide<br />

Engineering<br />

Guide<br />

DANAHER MOTION is a registered trademark of Danaher Corporation. Danaher Motion makes every attempt to ensure accuracy and reliability of the specifications in this publication. Specifications are subject to change without notice.<br />

Danaher Motion provides this information „AS IS“ and disclaims all warranties, express or implied, including, but not limited to, implied warranties of merchantability and fitness for a particular purpose.It is the responsibility of the product user<br />

to determine the suitability of this product for a specific application. ©2004 Danaher Motion.<br />

www.thomsonlinear.com 3<br />

Interchange<br />

Guide

<strong>Linear</strong> Motion. Optimized.<br />

Overview of Danaher Motion – Thomson <strong>Profile</strong> <strong>Rail</strong> <strong>Linear</strong> <strong>Guides</strong><br />

Since the invention of the linear anti-friction Ball Bushing<br />

bearing by Thomson over 50 years ago, the Thomson<br />

precision linear products have meant high quality,<br />

innovative products. Today, Danaher Motion continues<br />

producing and developing these high quality, innovative<br />

products. The Danaher Motion Thomson <strong>Profile</strong> <strong>Rail</strong><br />

assortment consists of the Next Generation <strong>Profile</strong><br />

<strong>Rail</strong> “500 Series” Ball and Roller <strong>Linear</strong> <strong>Guides</strong>, compact<br />

miniature “MicroGuide,“ lightweight “T-Series,”<br />

and AccuMini.<br />

The Danaher Motion <strong>Profile</strong> <strong>Rail</strong> – <strong>Linear</strong> Guide Assortment<br />

is a complete assortment of rails and carriages in a<br />

broad range of styles, sizes and unique features<br />

produced to industry standard dimensions for<br />

easy retrofitting into existing applications or designing<br />

into new applications.<br />

500 Series Ball <strong>Profile</strong> <strong>Rail</strong> <strong>Linear</strong> Guide<br />

Features & Benefits<br />

Superior Design. Superior Quality.<br />

• Straight rails through advanced<br />

grinding technologies<br />

• Simple installation and greater accuracy<br />

with joint-free rails up to 6 meters<br />

• Smooth, quiet movement through patented insert<br />

molded recirculation paths and optimized geometries<br />

• Extended lubrication life as a result of grease<br />

pockets built into the recirculation path<br />

• Multiple carriage styles and sizes available<br />

• On site field modifiable modular seals<br />

• <strong>Rail</strong> and carriage options from stock or short delivery<br />

• Customization with expanded accessory offering<br />

• Replaces AccuGlide<br />

Typical Applications<br />

• Industrial Automation<br />

• Machine Tool Equipment<br />

• Material Handling<br />

• Precision Measuring Equipment<br />

• Industrial Robots<br />

• Food Processing Equipment<br />

4<br />

www.thomsonlinear.com

<strong>Profile</strong> <strong>Rail</strong> <strong>Linear</strong> <strong>Guides</strong><br />

500 Series Ball<br />

<strong>Profile</strong> <strong>Rail</strong><br />

500 Series Roller <strong>Profile</strong> <strong>Rail</strong> <strong>Linear</strong> Guide<br />

Features & Benefits<br />

Superior Design. Superior Quality.<br />

• Industry leading load capacities<br />

• High rigidity from back to back four roller track arrangement<br />

• Straight rails through advanced grinding technologies<br />

• Simple installation and greater accuracy with jointfree<br />

rails up to 6 meters<br />

• Smooth, quiet movement through patented insert<br />

molded recirculation paths and optimized geometries<br />

• Multiple carriage styles and sizes available<br />

• On site field modifiable modular seals<br />

• <strong>Rail</strong> and carriage options from stock or short delivery<br />

• Customization with expanded accessory offering<br />

• Replaces Accumax<br />

Typical Applications<br />

• Industrial Automation<br />

• Material Handling<br />

• Industrial Robots<br />

• Machine Tool Equipment<br />

• Precision Measuring Equipment<br />

• Food Processing Equipment<br />

AccuMini<br />

Features & Benefits<br />

• Ball control design for smooth, quiet, low friction<br />

at high speeds<br />

• Full length integral wiper which protects important<br />

bearing from contaminants… effective system life<br />

is maximized<br />

• Gothic design, which provides high roll moment<br />

capacity...a requirement for stand-alone applications<br />

• Wear-resistant, engineered polymer retainer which<br />

reduces system inertia and noise<br />

Typical Applications<br />

• Wafer Handling Equipment<br />

• Assembly Equipment<br />

• Inspection and Measurement Equipment<br />

www.thomsonlinear.com 5

<strong>Linear</strong> Motion. Optimized.<br />

MicroGuide<br />

Features & Benefits<br />

• Industry standard drop-in replacement<br />

• 440 stainless steel construction (corrosion resistance,<br />

little or no lubrication)<br />

• High precision accuracy (up to ±0.010mm)<br />

• Extremely smooth, quiet operation<br />

• Unlimited stroke<br />

• Low <strong>Profile</strong><br />

• High Moment Load Capacity for single rail / carriage<br />

applications<br />

• Whisper quiet movement<br />

• Gothic arch ball groove geometry provides enables<br />

single rail application<br />

• Sizes: 5mm, 7mm, 9mm, 12mm, 15mm (MicroGuide<br />

standard)<br />

• Sizes: 7mm, 9mm, 12mm, 15mm (MicroGuide wide)<br />

• Technical engineering support from Danaher Motion<br />

• One-piece length up to 1 meter (in sizes 7mm - 15mm)<br />

• Contact Danaher Motion for custom lengths and<br />

configurations<br />

Typical Applications<br />

• Front end semiconductor processing equipment<br />

• Backend semiconductor packaging and handling<br />

equipment<br />

• Medical diagnostic and imaging equipment<br />

• Laboratory automation equipment<br />

• Testing and inspection equipment<br />

T-Series<br />

Features & Benefits<br />

• Lightweight, flexible and forgiving alternative to all-steel<br />

profile rail.<br />

• High quality product made from aircraft aluminum alloy<br />

with hardened steel load bearing plates and ball paths.<br />

• Ideal choice for applications requiring reduced weight<br />

inertia.<br />

• High flexibility translates into N class radial run out only.<br />

• Proprietary "U" channel construction allows the rail to<br />

"flex" to accommodate poor machine bases or<br />

misalignment errors.<br />

• Lower cost installation and reduced installation time by<br />

eliminating the need for a costly machined base and<br />

special tools.<br />

• Drop-in replacement for conventional all-steel profile<br />

linear guides.<br />

Typical Applications<br />

• Airplanes<br />

• Automobiles<br />

• Machine Tool<br />

• Ships<br />

• Packaging<br />

6<br />

www.thomsonlinear.com

Assortment<br />

<strong>Profile</strong> <strong>Rail</strong> <strong>Linear</strong> <strong>Guides</strong><br />

500 Series Ball<br />

<strong>Profile</strong> <strong>Rail</strong><br />

SIZE MM<br />

500 Series Ball 500 Series Roller AccuMini MicroGuide T-Series<br />

Standard Narrow Standard Narrow Standard Standard Wide Standard<br />

––– Long Long Long Short Long Long<br />

––– ––– ––– ––– High High ––– ––– ––– ––– ––– ––– ––– ––– ––– –––<br />

5 •<br />

7 • •<br />

9 • •<br />

10 •<br />

12 • •<br />

15 • • • • • • •<br />

20 • • • • • • • • • •<br />

25 • • • • • • • • • • • • • •<br />

30 • • • • • •<br />

35 • • • • • • • • • • • • • •<br />

45 • • • • • • • •<br />

55 • • • •<br />

65 • • • •<br />

Style A B C D E F G A B C D A N/A N/A A G E F<br />

Page 21 21 23 23 25 25 27 55 55 57 57 75 78 80 87 87 89 89<br />

Application Criteria<br />

Feature 500 Series Ball 500 Series Roller AccuMini MicroGuide T-Series<br />

Load Capacity ••• •••• •• • ••<br />

Equivalent Loads all directions ••• •••• •• •• •<br />

Ultra Compactness • • ••• •••• •<br />

High Travel Accuracy •••• •••• •••• •••• •••<br />

Rigidity ••• •••• •• •• •<br />

Smoothness ••• •• •••• •••• •••<br />

Friction Characteristic •••• •• •••• •••• ••<br />

Admissable Speed •••• ••• •••• •••• •••<br />

Ease of Installation ••• •• •• ••• ••••<br />

Lightweight • • •• ••• ••••<br />

Industry Standard Dimensions •••• •••• •••• ••••<br />

Page 8 44 73 77 84<br />

• = satisfactory •••• = excellent<br />

www.thomsonlinear.com 7

<strong>Linear</strong> Motion. Optimized.<br />

<strong>Profile</strong> <strong>Rail</strong> <strong>Linear</strong> <strong>Guides</strong><br />

500 Series Ball <strong>Profile</strong> <strong>Rail</strong> <strong>Linear</strong> Guide<br />

High load capacities<br />

in all directions<br />

Industry standard dimensions<br />

Patented insert molded<br />

recirculation path with grease<br />

pockets resulting in quiet,<br />

low noise operation<br />

Multiple carriage designs,<br />

accuracies and preloads available<br />

Multiple rail accuracies<br />

Optimized ball path geometries and<br />

transitions for quiet, smooth operation<br />

One piece rail length up to 6 meters<br />

(size 25 and up)<br />

Multiple rail mounting hole plug options,<br />

or rails that mount up from underneath<br />

are available<br />

Both sides of rail are reference edges<br />

Six-runner block attachment bolts<br />

per carriage for superior system<br />

rigidity<br />

Universal mounting holes–runner blocks can be<br />

attached from top or bottom<br />

Multiple lubrication inlet points, easy<br />

field modification<br />

Superior rail straightness as a result<br />

of advanced grinding and straightening<br />

technology<br />

Modular accessories for on site<br />

upgrade without having to<br />

remove the carriage from the rail<br />

Corrosion resistance with Duralloy ®<br />

Thin Dense Chrome plating optional<br />

Low drag longitudinal seals standard for<br />

added protection along rail surface<br />

Removable double lip seal<br />

or low drag seal<br />

Extended standard dowel hole<br />

options for rails and carriages<br />

Complete interchangeability<br />

between rails and carriages<br />

Two point ball contact resulting<br />

in low friction<br />

High rigidity from optimized<br />

trapezoidal profile, allows for<br />

single carriage application<br />

Speeds up to 5 m/s<br />

Accelerations up to 100 m/s 2<br />

8<br />

www.thomsonlinear.com

500 Series Ball <strong>Profile</strong> <strong>Rail</strong> <strong>Linear</strong> Guide<br />

<strong>Profile</strong> <strong>Rail</strong> <strong>Linear</strong> <strong>Guides</strong><br />

500 Series Ball<br />

<strong>Profile</strong> <strong>Rail</strong><br />

Features<br />

The Thomson 500 Series Ball <strong>Linear</strong> Guide provides long life,<br />

exceptional rigidity, high dynamic and static load capa cities,<br />

accommodation for high moment loads, high running<br />

accuracy, multiple sealing options and multiple lubrication<br />

inlet options. This allows for on-site field modifications, and<br />

interchangeability with competitor offering.<br />

These properties result in improved machine accuracies and<br />

rigidity resulting in reduced vibration extending machine and<br />

tool life. This has a direct effect on operational efficiency<br />

resulting in cost savings for the user.<br />

Available in 7 carriage designs, and sizes 15 to 45mm.<br />

Materials <strong>Linear</strong> <strong>Guides</strong><br />

The 500 Series Ball <strong>Linear</strong> <strong>Guides</strong> are produced from high<br />

quality bearing steel. All carriages and rolling elements are<br />

through hardened and all rails are case hardened (except<br />

size 15 rail which is through hardened). The end cap is<br />

constructed of a high strength, glass filled nylon with nitrile<br />

rubber seal. Stringent quality controls are in place to ensure<br />

consistency of materials from the source, allowing us to<br />

ensure that we delivery the highest quality product.<br />

Interchangeability<br />

The 500 Series Ball <strong>Linear</strong> <strong>Guides</strong> are completely<br />

interchangeable. Any carriage can be run on any rail of the<br />

same accuracy without compromising system accuracy.<br />

This is the result of our stringent manufacturing process<br />

controls.<br />

Accuracy and Preload<br />

The 500 Series Ball <strong>Linear</strong> <strong>Guides</strong> are available in three<br />

different accuracy classes, three different preload ranges<br />

and with clearance to allow for customization to your<br />

appli cation needs.<br />

Straightness<br />

The 500 Series Ball rail is subjected to multiple straightening<br />

processes during and after grinding of the roller paths.<br />

These added processes and inspections result in some of<br />

the straightest rails in the market today, improving machine<br />

accuracies wherever the 500 Series Ball is used.<br />

Rigidity<br />

The 500 Series Ball <strong>Linear</strong> Guide rail utilizes a special<br />

trapezoidal profile that maximizes the carriage cross<br />

section, resulting in the highest possible rigidity.<br />

www.thomsonlinear.com 9

<strong>Linear</strong> Motion. Optimized.<br />

<strong>Profile</strong> <strong>Rail</strong> <strong>Linear</strong> <strong>Guides</strong><br />

500 Series Ball <strong>Profile</strong> <strong>Rail</strong> <strong>Linear</strong> Guide<br />

Running Smoothness / Low Noise<br />

The running smoothness and low noise are the result of<br />

a patented, custom insert molded recirculation path that has<br />

an optimized geometric shape and minimal transitions, to<br />

ensure smooth and quiet operation in both low and high-speed<br />

operation.<br />

In addition, the balls make contact at only two points<br />

between rail and carriage. As a result, friction is reduced to<br />

a minimum, resulting in quiet, smooth operation.<br />

Back-to-Back<br />

The 500 Series <strong>Linear</strong> Guide utilizes a back-to-back bearing<br />

arrangement, resulting in added rigidity. As a result, the 500<br />

Series Ball can be used in single rail applications.<br />

Internal Grease Pockets<br />

The patented insert molded recirculation path has built in<br />

grease pockets. These provide an extra level of security by<br />

ensuring adequate lubrication is available to the ball bearings<br />

to help extend life.<br />

The pocket and area between the balls provide greater grease<br />

quantities in the ball path than a conventional<br />

designed linear guide bearing.<br />

Multiple Lubrication Options<br />

The standard end cap is designed for flexibility. The end cap<br />

comes standard with four lubrication inlet options. These<br />

inlet options are easily changed on-site in the field or can be<br />

supplied from the factory.<br />

Unsure of the best lubrication inlet location? These carriages<br />

allow the user to make these changes easily in the field to<br />

optimize the system performance. In addition, they allow for<br />

ease in maintenance – all without removing the carriage from<br />

the rail.<br />

10<br />

www.thomsonlinear.com

500 Series Ball <strong>Profile</strong> <strong>Rail</strong> <strong>Linear</strong> Guide<br />

<strong>Profile</strong> <strong>Rail</strong> <strong>Linear</strong> <strong>Guides</strong><br />

500 Series Ball<br />

<strong>Profile</strong> <strong>Rail</strong><br />

Modular Accessory Options<br />

The standard carriage is supplied with low friction<br />

double lip seals and longitudinal seals that completely<br />

encase the bearing carriage to protect the balls and track<br />

surfaces and minimize lubrication loss.<br />

Optional metal scrapers or wipers, lube blocks and oil<br />

reservoir components can be easily added on-site in the<br />

field or can be supplied assembled from the factory.<br />

The trapezoidal rail profile allows for easy servicing and<br />

replacing or adding of the end cap, additional wiper and<br />

oil reservoir without removing the carriage from the<br />

rail.<br />

These innovative design features allow users to easily,<br />

efficiently, and economically upgrade carriage sealing.<br />

Longitudinal Seals<br />

The carriage has built-in under carriage low drag longitudinal<br />

seals that protect the balls and ball path from<br />

contamination. These longitudinal seals are an added<br />

protection to increase the life and overall performance.<br />

Extended Standards<br />

Extended Standards are an assortment of Danaher Motion<br />

dowel hole options for both carriage and rail products.<br />

Take the guesswork out of design by using our standard<br />

assortment of dowel hole options for ease of design and<br />

availability, another solution from Danaher Motion. Refer<br />

to page 29, 30 and 33 for more information and detailed<br />

datasheets.<br />

<strong>Rail</strong> Accessories<br />

The rails have multiple options to protect the mounting<br />

holes to eliminate possible contamination entry into the<br />

bearing. Custom designed plastic plugs, mylar tape and<br />

stainless steel rail cover strip are available.<br />

Retained Balls<br />

The rolling elements of the carriages are retained within<br />

the bearing so the carriage can be removed from the rail<br />

without worrying about the balls falling out. It is recommended<br />

to place any removed carriage onto an assembly<br />

rail or shipping arbor to provide added protection to the<br />

rolling elements.<br />

www.thomsonlinear.com 11

<strong>Linear</strong> Motion. Optimized.<br />

500 Series <strong>Profile</strong> <strong>Rail</strong> Enhanced Carriage<br />

New, 66% Smoother Running Design, with 50%<br />

Lower Drag Force *<br />

New Ball Spacer and Stainless Steel Options<br />

Features and Benefits<br />

Now available in all sizes: the new Thomson 500 Series<br />

<strong>Profile</strong> <strong>Rail</strong> enhanced carriage design can improve the<br />

smoothness and precision of your linear motion application.<br />

New optional 440B stainless carriages and rails provide<br />

corrosion resistance well-suited for medical, food, electronic<br />

assembly and semiconductor applications.<br />

• New ball spacer carriage option provides smooth, quiet<br />

motion.<br />

• New, smoother running design optimizes the surface<br />

interfaces between steel and plastic transition areas along<br />

the ball bearing circulation path.<br />

• New standard end seals provide twice the contaminant<br />

protection compared to competitive products. Optional low<br />

drag end seals are ideal for low push force requirements.<br />

• Four longitudinal seals per carriage provide much better<br />

contaminant protection than competitive designs with<br />

only two longitudinal seals.<br />

• Additional lubrication reservoir enables longer running<br />

time and easy change end caps & seals are quick to<br />

replace.<br />

• 100% interchangeable with previous Thomson 500 Series<br />

carriage and rail.<br />

* 66% smoothness increase measured as variability of drag force while the<br />

carriage is in motion. 50% lower drag force measured with new low drag<br />

seals option; 41% lower drag force measured with standard wiper option.<br />

12<br />

www.thomsonlinear.com

500 Series Ball <strong>Profile</strong> <strong>Rail</strong> <strong>Linear</strong> Guide<br />

<strong>Profile</strong> <strong>Rail</strong> <strong>Linear</strong> <strong>Guides</strong><br />

500 Series Ball<br />

<strong>Profile</strong> <strong>Rail</strong><br />

Modular Accessory Exploded View<br />

Standard end cap<br />

(531 EC)<br />

Integral double lip seal<br />

Standard end cap*<br />

(531 EC)<br />

Recirculation path<br />

Oil reservoir*<br />

(531 OW)<br />

Balls<br />

Additional wiper*<br />

(531 WR or VR)<br />

Metal scraper<br />

(531 ZZ)<br />

Plastic plugs<br />

(531 HP)<br />

<strong>Rail</strong><br />

(521)<br />

Grease fitting<br />

Attaching bolts<br />

Also available (not shown):<br />

• Lube Block (531 LL)<br />

• Mylar <strong>Rail</strong> Tape (531 RT)<br />

• Bolt up from bottom rail (521 Type U)<br />

• Stainless Steel <strong>Rail</strong>, Cover Strip and <strong>Rail</strong> (521 Type C<br />

and 531RCS)<br />

* Can be installed without removing carriage from the<br />

rail<br />

The modular building block design of the 500 Series Ball<br />

<strong>Profile</strong> <strong>Rail</strong> <strong>Linear</strong> Guide assembly allows for easy on-site<br />

field upgrades for quick seal or lubrication changes, all<br />

without the need to remove the carriage from the rail.<br />

www.thomsonlinear.com 13

www.thomsonlinear.com<br />

14<br />

<strong>Linear</strong> Motion. Optimized.<br />

500 Series Ball Standard Carriages<br />

15<br />

20<br />

25<br />

30<br />

35<br />

45<br />

20<br />

25<br />

30<br />

35<br />

45<br />

15<br />

20<br />

25<br />

30<br />

35<br />

20<br />

25<br />

30<br />

35<br />

1500<br />

3000<br />

6000<br />

6000<br />

6000<br />

6000<br />

3000<br />

6000<br />

6000<br />

6000<br />

6000<br />

1500<br />

3000<br />

6000<br />

6000<br />

6000<br />

3000<br />

6000<br />

6000<br />

6000<br />

511H15A0<br />

-<br />

-<br />

511H20A0<br />

-<br />

-<br />

511H25A0<br />

-<br />

-<br />

511H30A0<br />

-<br />

-<br />

511H35A0<br />

-<br />

-<br />

511H45A0<br />

-<br />

-<br />

511H20B0<br />

-<br />

-<br />

511H25B0<br />

-<br />

-<br />

511H30B0<br />

-<br />

-<br />

511H35B0<br />

-<br />

-<br />

511H45B0<br />

-<br />

-<br />

511H15C0<br />

-<br />

-<br />

511H20C0<br />

-<br />

-<br />

511H25C0<br />

-<br />

-<br />

511H30C0<br />

-<br />

-<br />

511H35C0<br />

-<br />

-<br />

511H20D0<br />

-<br />

-<br />

511H25D0<br />

-<br />

-<br />

511H30D0<br />

-<br />

-<br />

511H35D0<br />

-<br />

-<br />

H<br />

P<br />

U<br />

H<br />

P<br />

U<br />

H<br />

P<br />

U<br />

H<br />

P<br />

U<br />

H<br />

P<br />

U<br />

H<br />

P<br />

U<br />

H<br />

P<br />

U<br />

H<br />

P<br />

U<br />

H<br />

P<br />

U<br />

H<br />

P<br />

U<br />

H<br />

P<br />

U<br />

H<br />

P<br />

U<br />

H<br />

P<br />

U<br />

H<br />

P<br />

U<br />

H<br />

P<br />

U<br />

H<br />

P<br />

U<br />

H<br />

P<br />

U<br />

H<br />

P<br />

U<br />

H<br />

P<br />

U<br />

H<br />

P<br />

U<br />

511H15A1<br />

511P15A1<br />

511U15A1<br />

511H20A1<br />

511P20A1<br />

511U20A1<br />

511H25A1<br />

511P25A1<br />

511U25A1<br />

511H30A1<br />

511P30A1<br />

511U30A1<br />

511H35A1<br />

511P35A1<br />

511U35A1<br />

511H45A1<br />

511P45A1<br />

511U45A1<br />

511H20B1<br />

511P20B1<br />

511U20B1<br />

511H25B1<br />

511P25B1<br />

511U25B1<br />

511H30B1<br />

511P30B1<br />

511U30B1<br />

511H35B1<br />

511P35B1<br />

511U35B1<br />

511H45B1<br />

511P45B1<br />

511U45B1<br />

511H15C1<br />

511P15C1<br />

511U15C1<br />

511H20C1<br />

511P20C1<br />

511U20C1<br />

511H25C1<br />

511P25C1<br />

511U25C1<br />

511H30C1<br />

511P30C1<br />

511U30C1<br />

511H35C1<br />

511P35C1<br />

511U35C1<br />

511H20D1<br />

511P20D1<br />

511U20D1<br />

511H25D1<br />

511P25D1<br />

511U25D1<br />

511H30D1<br />

511P30D1<br />

511U30D1<br />

511H35D1<br />

511P35D1<br />

511U35D1<br />

511H15A2<br />

511P15A2<br />

511U15A2<br />

511H20A2<br />

511P20A2<br />

511U20A2<br />

511H25A2<br />

511P25A2<br />

511U25A2<br />

511H30A2<br />

511P30A2<br />

511U30A2<br />

511H35A2<br />

511P35A2<br />

511U35A2<br />

511H45A2<br />

511P45A2<br />

511U45A2<br />

511H20B2<br />

511P20B2<br />

511U20B2<br />

511H25B2<br />

511P25B2<br />

511U25B2<br />

511H30B2<br />

511P30B2<br />

511U30B2<br />

511H35B2<br />

511P35B2<br />

511U35B2<br />

511H45B2<br />

511P45B2<br />

511U45B2<br />

511H15C2<br />

511P15C2<br />

511U15C2<br />

511H20C2<br />

511P20C2<br />

511U20C2<br />

511H25C2<br />

511P25C2<br />

511U25C2<br />

511H30C2<br />

511P30C2<br />

511U30C2<br />

511H35C2<br />

511P35C2<br />

511U35C2<br />

511H20C2<br />

511P20D2<br />

511U20D2<br />

511H25D2<br />

511P25D2<br />

511U25D2<br />

511H30D2<br />

511P30D2<br />

511U30D2<br />

511H35D2<br />

511P35D2<br />

511U35D2<br />

-<br />

511P15A3<br />

511U15A3<br />

-<br />

511P20A3<br />

511U20A3<br />

-<br />

511P25A3<br />

511U25A3<br />

-<br />

511P30A3<br />

511U30A3<br />

-<br />

511P35A3<br />

511U35A3<br />

-<br />

511P45A3<br />

511U45A3<br />

-<br />

511P20B3<br />

511U20B3<br />

-<br />

511P25B3<br />

511U25B3<br />

-<br />

511P30B3<br />

511U30B3<br />

-<br />

511P35B3<br />

511U35B3<br />

-<br />

511P45B3<br />

511U45B3<br />

-<br />

511P15C3<br />

511U15C3<br />

-<br />

511P20C3<br />

511U20C3<br />

-<br />

511P25C3<br />

511U25C3<br />

-<br />

511P30C3<br />

511U30C3<br />

-<br />

511P35C3<br />

511U35C3<br />

-<br />

511P20D3<br />

511U20D3<br />

-<br />

511P25D3<br />

511U25D3<br />

-<br />

511P30D3<br />

511U30D3<br />

-<br />

511P35D3<br />

511U35D3<br />

521H15A<br />

521P15A<br />

521U15A<br />

521H20A<br />

521P20A<br />

521U20A<br />

521H25A<br />

521P25A<br />

521U25A<br />

521H30A<br />

521P30A<br />

521U30A<br />

521H35A<br />

521P35A<br />

521U35A<br />

521H45A<br />

521P45A<br />

521U45A<br />

521H20A<br />

521P20A<br />

521U20A<br />

521H25A<br />

521P25A<br />

521U25A<br />

521H30A<br />

521P30A<br />

521U30A<br />

521H35A<br />

521P35A<br />

521U35A<br />

521H45A<br />

521P45A<br />

521U45A<br />

521H15A<br />

521P15A<br />

521U15A<br />

521H20A<br />

521P20A<br />

521U20A<br />

521H25A<br />

521P25A<br />

521U25A<br />

521H30A<br />

521P30A<br />

521U30A<br />

521H35A<br />

521P35A<br />

521U35A<br />

521H20A<br />

521P20A<br />

521U20A<br />

521H25A<br />

521P25A<br />

521U25A<br />

521H30A<br />

521P30A<br />

521U30A<br />

521H35A<br />

521P35A<br />

521U35A<br />

Size<br />

Style<br />

Standard<br />

Carriage<br />

A<br />

B<br />

C<br />

Narrow<br />

Long<br />

Carriage<br />

Narrow<br />

Carriage<br />

Standard<br />

Long<br />

Carriage<br />

D<br />

Accuracy Clearance 0.03C 0.08C<br />

Preload<br />

Basic Part Number<br />

0.13C<br />

Appropriate <strong>Rail</strong><br />

Standard Style<br />

Max. Single Piece<br />

<strong>Rail</strong> Length (mm)<br />

Danaher Motion offers six carriage styles with six mounting<br />

holes allowing for additional mounting configurations in<br />

the field or for retrofitting. All provide superior rigidity and<br />

design flexibility.

<strong>Profile</strong> <strong>Rail</strong> <strong>Linear</strong> <strong>Guides</strong><br />

500 Series Ball<br />

<strong>Profile</strong> <strong>Rail</strong><br />

Narrow<br />

High<br />

Carriage<br />

Narrow<br />

High<br />

Long<br />

Carriage<br />

Narrow<br />

Short<br />

Carriage<br />

Style<br />

E<br />

F<br />

G<br />

Size<br />

15<br />

25<br />

30<br />

35<br />

45<br />

25<br />

30<br />

35<br />

45<br />

15<br />

20<br />

Basic Part Number<br />

Accuracy Preload<br />

Clearance 0.03C 0.08C<br />

H<br />

P<br />

U<br />

H<br />

P<br />

U<br />

H<br />

P<br />

U<br />

H<br />

P<br />

U<br />

H<br />

P<br />

U<br />

H<br />

P<br />

U<br />

H<br />

P<br />

U<br />

H<br />

P<br />

U<br />

H<br />

P<br />

U<br />

H<br />

P<br />

U<br />

H<br />

P<br />

U<br />

511H15E0<br />

-<br />

-<br />

511H25E0<br />

-<br />

-<br />

511H30E0<br />

-<br />

-<br />

511H35E0<br />

-<br />

-<br />

511H45E0<br />

-<br />

-<br />

511H25F0<br />

-<br />

-<br />

511H30F0<br />

-<br />

-<br />

511H35F0<br />

-<br />

-<br />

511H45F0<br />

-<br />

-<br />

511H15G0<br />

-<br />

-<br />

511H20G0<br />

-<br />

-<br />

511H15E1<br />

511P15E1<br />

511U15E1<br />

511H25E1<br />

511P25E1<br />

511U25E1<br />

511H30E1<br />

511P30E1<br />

511U30E1<br />

511H35E1<br />

511P35E1<br />

511U35E1<br />

511H45E1<br />

511P45E1<br />

511U45E1<br />

511H25F1<br />

511P25F1<br />

511U25F1<br />

511H23F1<br />

511P30F1<br />

511U30F1<br />

511H35F1<br />

511P35F1<br />

511U35F1<br />

511H45F1<br />

511P45F1<br />

511U45F1<br />

511H15G1<br />

511P15G1<br />

511U15G1<br />

511H20G1<br />

511P20G1<br />

511U20G1<br />

511H15E2<br />

511P15E2<br />

511U15E2<br />

511H25E2<br />

511P25E2<br />

511U25E2<br />

511H30E2<br />

511P30E2<br />

511U30E2<br />

511H35E2<br />

511P35E2<br />

511U35E2<br />

511H45E2<br />

511P45E2<br />

511U45E2<br />

511H25F2<br />

511P25F2<br />

511U25F2<br />

511H30F2<br />

511P30F2<br />

511U30F2<br />

511H35F2<br />

511P35F2<br />

511U35F2<br />

511H45F2<br />

511P45F2<br />

511U45F2<br />

511H15G2<br />

511P15G2<br />

511U15G2<br />

511H20G2<br />

511P20G2<br />

511U20G2<br />

0.13C<br />

-<br />

511P15E3<br />

511U15E3<br />

-<br />

511P25E3<br />

511U25E3<br />

-<br />

511P30E3<br />

511U30E3<br />

-<br />

511P35E3<br />

511U35E3<br />

-<br />

511P45E3<br />

511U45E3<br />

-<br />

511P20F3<br />

511U20F3<br />

-<br />

511P30F3<br />

511U30F3<br />

-<br />

511P35F3<br />

511U35F3<br />

-<br />

511P45F3<br />

511U45F3<br />

-<br />

511P15G3<br />

511U15G3<br />

-<br />

511P20G3<br />

511U20G3<br />

Appropriate <strong>Rail</strong><br />

Standard Style<br />

521H15A<br />

521P15A<br />

521U15A<br />

521H25A<br />

521P25A<br />

521U25A<br />

521H30A<br />

521P30A<br />

521U30A<br />

521H35A<br />

521P35A<br />

521U35A<br />

521H45A<br />

521P45A<br />

521U45A<br />

521H25A<br />

521P25A<br />

521U25A<br />

521H30A<br />

521P30A<br />

521U30A<br />

521H35A<br />

521P35A<br />

521U35A<br />

521H45A<br />

521P45A<br />

521U45A<br />

521H15A<br />

521P15A<br />

521U15A<br />

521H20A<br />

521P20A<br />

521U20A<br />

Max. Single Piece<br />

<strong>Rail</strong> Length (mm)<br />

1500<br />

6000<br />

6000<br />

6000<br />

6000<br />

6000<br />

6000<br />

6000<br />

6000<br />

1500<br />

3000<br />

Type A<br />

Type U<br />

Extended Standard Carriage Options<br />

The carriages are also available with the Thomson standard dowel holes or lubrication<br />

inlets as shown on pages 29 to 33 or special lubricants either from stock or with a short<br />

lead-time.<br />

<strong>Rail</strong> Types and Accessories<br />

The rails are available in two configurations:<br />

• Bolt down from the top – 521 Type A<br />

• Bolt up from the bottom – 521 Type U<br />

The standard 521 rail mounting holes can be plugged or sealed after installation with the<br />

options below.<br />

Plastic Plugs<br />

531HP plastic plugs are an inexpensive and simple method to seal the rail attachment<br />

bolt area. The plastic plugs are easily driven in place to any rail with a soft non-metallic<br />

drift. They can easily be removed.<br />

Mylar Tape<br />

A simple and low cost alternative is specialty Mylar tape that can be placed quickly on<br />

the top surface of the rail. Part number 531RT is available in 3 meter lengths.<br />

Stainless Steel Cover Strip<br />

Option 531RCS utilizes a special rail (521 Type C) and stainless steel cover strip that is<br />

easily installed with the proper mounting tool.<br />

www.thomsonlinear.com 15

<strong>Linear</strong> Motion. Optimized.<br />

Additional Seal Types and Lubrication Accessories<br />

The carriage is designed with modular sealing and<br />

lubrication options for simple on-site field modification<br />

or can be supplied factory direct.<br />

The standard carriage end cap has an integral low friction<br />

double lip seal and longitudinal seal that completely<br />

encase the bearing carriage. The double lip design<br />

keeps contaminants out and lubrication in. It also allows<br />

for grease to purge out of the carriage to prevent<br />

excessive lubrication, which can result in higher operating<br />

temperatures. This double lip design can be used with oil<br />

lubrication.<br />

The standard carriage end cap is equipped with a lubrication<br />

inlet centered with a specially designed lubricant<br />

channel to direct the lubrication to individual ball tracks.<br />

The lubrication inlet can be easily changed in the field<br />

or supplied from the factory with a side inlet or top inlet.<br />

Additional Seal<br />

The 531 WR and 531 VR seals provide an additional<br />

level of protection from contaminants to the assembly.<br />

These additional components can easily be added on-site<br />

without removing the carriage from the rail. They are<br />

supplied with the required screws to make the installation<br />

simple.<br />

• 531 WR is constructed from durable nitrile rubber (Buna N)<br />

• 531 VR is constructed from durable Viton ®<br />

These seals can be used in conjunction with other<br />

optional modular accessories providing an easy upgrade<br />

to the standard seal. These can be easily installed on-site<br />

in the field or can be supplied from the factory.<br />

Metal Scraper<br />

The Type 531 ZZ Metal Scraper made of stainless steel,<br />

serves as an added protection to the seal lips against<br />

large dirt particles, metal shavings or chips. Large<br />

contaminants are easily pushed away providing an extra<br />

level of protection to the seal lips. The Metal Scraper<br />

is easily installed in conjunction with the other optional<br />

modular accessories providing you with an easy upgrade<br />

to the standard seal. These can be easily installed on-site<br />

in the field or can be supplied from the factory.<br />

16<br />

www.thomsonlinear.com

<strong>Profile</strong> <strong>Rail</strong> <strong>Linear</strong> <strong>Guides</strong><br />

500 Series Ball<br />

<strong>Profile</strong> <strong>Rail</strong><br />

Oil Reservoir<br />

The Type 531 OW oil reservoir is a cost effective, automatic<br />

lubrication system. It is constructed with an integrated oil<br />

reservoir that provides a uniform, consistent lubricating<br />

oil to the ball paths for extended periods of time. The Type<br />

531 OW oil reservoir lubrication plate eliminates the need<br />

for a routine maintenance schedule, assures lubrication<br />

gets to the required points, can be refilled if required, and<br />

can operate up to 5000 km of travel. The Type 531 OW oil<br />

reservoir can be easily installed in conjunction with other<br />

optional modular accessories providing an easy upgrade<br />

to the standard seals. These can be easily installed<br />

on-site in the field or can be supplied from the factory.<br />

Lube Block<br />

The 531 LL Lube Block is a solid lubricant that is a mixture<br />

of polymers, oils and selected additives that reduce the<br />

penetration of dirt, grit, and liquids into the ball path, preventing<br />

premature failures. The oil diffuses, lubricating the<br />

ball path surfaces by capillary action. Additional oil is supplied<br />

to the ball path surfaces from the polymer. For additional<br />

protection the assembly is packed with EP2 grease. There<br />

is no need for maintenance or additional lubrication during<br />

the life of the Lube Block filled bearing. The 531 LL Lube<br />

Block can be easily installed in conjunction with the other<br />

optional modular accessories providing an easy upgrade<br />

to the standard seal. These can be easily installed on-site<br />

in the field or can be supplied from the factory.<br />

Relative Drag Comparison for Design Consideration<br />

Type<br />

Standard carriage<br />

Rubber Wiper (531 WR)<br />

Viton ® Wiper (531 VR)<br />

Metal Scraper (531 ZZ)<br />

Oil Reservoir (531 OW)<br />

Lube Block (531 LL)<br />

• Low<br />

Relative Drag<br />

•<br />

• • •<br />

• • •<br />

•<br />

• •<br />

• • • •<br />

For ordering information<br />

or for additional<br />

Seal Types and<br />

Lubrication Accessories,<br />

see pages 37 to 38.<br />

Bellows<br />

Standard bellows are available for all assemblies. The<br />

bellows cover the entire length of the rail. The bellows<br />

are used to provide additional protection against dirt, dust<br />

and splashed liquids. Installation is simple and requires<br />

little time. Retrofitting is possible when the rail ends are<br />

drilled for the attachment of the end plate 531. Bellows<br />

are available in three styles:<br />

• Type B “Low <strong>Profile</strong>” with outside dimensions that do<br />

not exceed the carriage<br />

• Type C “High Compression”<br />

• Type W “Walk On” capable of handling the harshest<br />

environments with a 90kg load bearing capacity<br />

The bellow can be easily installed in conjunction with<br />

other optional modular seals providing you with a simple<br />

upgrade to the standard seal. These can be installed<br />

on-site in the field or can be supplied from the factory.<br />

Note: Additional modular accessories add additional drag<br />

to the carriage assembly resulting in increased start up<br />

friction and power consumption.<br />

www.thomsonlinear.com 17

<strong>Linear</strong> Motion. Optimized.<br />

500 Series Ball Spacer<br />

500 Series Ball <strong>Profile</strong> <strong>Rail</strong> carriages are now available with<br />

ball spacer elements that significantly reduce the running<br />

noise of the carriage. The ball spacer carriage is available<br />

in sizes 20, 25, 30, 35 and 45. It is a drop-in replacement for<br />

the current ball carriage; all external carriage dimensions<br />

are exactly the same.<br />

The noise reduction is achieved by inserting plastic discs<br />

between each ball bearing. This reduces noise by preventing<br />

the balls from contacting each other as well as bumping<br />

into the ball track. The addition of the plastic discs requires<br />

a reduced number of load carrying balls, which leads to a<br />

slight reduction of the static and dynamic load capacity of<br />

the ball spacer carriage.<br />

Features and Benefits:<br />

• Significant noise reduction (-6 dB)<br />

• Minimum reduction of dynamic and static load capacity-<br />

Contact Danaher Motion Application Engineering for<br />

load rating details<br />

• Drop-in replacement for 511 ball carriage<br />

• Same accessory options as 511 ball carriage<br />

• Better or identical performance in comparison to<br />

competitor push force and noise<br />

• Carriage type designation: 513<br />

Noise Measurement, 35mm Carriage<br />

Old design<br />

Ball Spacer Technology Comparison<br />

Thomson Ball Spacer<br />

Enhanced design<br />

Enhanced design<br />

(with ball spacer)<br />

Competitor 1<br />

(without caged ball)<br />

Competitor 2<br />

(without caged ball)<br />

Competitor 2<br />

(with caged ball)<br />

62 64 66 68 70 72 74 76<br />

Noise, dB(A) at 1m/s<br />

Competitor Ball Chain<br />

Spacer<br />

Ball<br />

Ball Spacer Spacer Link<br />

Thomson 513 Ball Spacer<br />

Competitor Ball Chain<br />

Internal Forces No tensile load Tensile load on spacer links<br />

Quality Automatic inspection of each spacer element Optical inspection not possible without bending link<br />

Balltrack<br />

clearances<br />

Any clearance between balls and spacers is<br />

minimized during assembly<br />

Spacer link tolerances leads to undefined<br />

clearances<br />

Push Force Slight increase in push force Significant increase in push force<br />

Reliability Fewer elements = fewer failure modes Broken link elements can block re-circulation path<br />

18<br />

www.thomsonlinear.com

500 Series Ball<br />

<strong>Profile</strong> <strong>Rail</strong> <strong>Linear</strong> <strong>Guides</strong><br />

500 Series Ball<br />

<strong>Profile</strong> <strong>Rail</strong><br />

Part Numbering Description<br />

Ball Carriage<br />

STANDARD Standard<br />

OPTIONS<br />

5 1 1 H 15 A 1 D L W Z ES1 SM<br />

500 Series<br />

<strong>Profile</strong> Carriage<br />

Specials<br />

SM Special per customer print<br />

Product Type<br />

1 Carriage<br />

Type<br />

1 Ball<br />

3 Ball Spacer<br />

Accuracy Class 2<br />

H High Grade<br />

P Precision Grade<br />

U Ultra Precision Grade<br />

Carriage Style<br />

A Standard<br />

B Standard Long<br />

C Narrow<br />

D Narrow Long<br />

E Narrow High<br />

F Narrow Long High<br />

G Narrow Short<br />

4<br />

Size<br />

15 30<br />

20 35<br />

25 45<br />

Preload<br />

0 Clearance<br />

1 Approximately 0.03 C<br />

2 Approximately 0.08 C<br />

3 Approximately 0.13 C<br />

Extended Standards - Options<br />

ES1 6mm Dowel Hole - Slip Fit<br />

ES2 10mm Dowel Hole - Slip Fit<br />

ES3 1/4” Dowel Hole - Slip Fit<br />

ES4 3/8” Dowel Hole - Slip Fit<br />

ES10 Side lubrication in end caps<br />

ES11 Top lubrication in end caps<br />

ES12 (2) 6mm Dowel Holes - Press Fit<br />

ES13 (2) 10mm Dowel Holes - Press Fit<br />

ES14 (2) 1/4” Dowel Holes - Press Fit<br />

ES15 (2) 3/8” Dowel Holes - Press Fit<br />

G1 Greased with Mobilux ® EP2<br />

G2<br />

GS<br />

Corrosion-resistant Option<br />

®<br />

D Duralloy Thin Dense Chrome<br />

S Stainless Steel Material<br />

(available in sizes 15 and<br />

20 and carriage styles A and<br />

C only)<br />

Greased with Krytox ® GPL227<br />

Greased per customer<br />

specification<br />

Accessories 1<br />

L Long Life Lube Block<br />

N Additional Oil Reservoir<br />

W Additional Rubber Wiper<br />

V Additional Viton Wiper<br />

Z Metal Scraper<br />

C Bellow Clips<br />

K Low Drag Seal<br />

1. Accessory combination part numbers are listed from carriage end cap<br />

outward. Not all combinations are available. For specific combination<br />

availability see pages 35-36.<br />

3. New enhanced carriage does not retain ball bearings when end cap<br />

is removed. Removal of end caps can result in loss of ball bearings.<br />

4. Ball Spacer carriage not available in size 15.<br />

2. The 500 Series Ball lowest accuracy grade is High as a result of tight<br />

manufacturing controls and grinding capabilities. We do not offer<br />

Normal grade accuracy, our High grade is our Normal grade.<br />

www.thomsonlinear.com 19

<strong>Linear</strong> Motion. Optimized.<br />

500 Series Ball<br />

Part Numbering Description<br />

Ball <strong>Rail</strong><br />

Type<br />

1 Ball<br />

500 Series<br />

<strong>Profile</strong> <strong>Rail</strong><br />

Product Type<br />

2 <strong>Rail</strong><br />

STANDARD<br />

OPTIONS<br />

STANDARD<br />

5 2 1 H 15 A D DH1 SM +xxxx Y= (see note 1)<br />

Length (mm)<br />

xxxx Customer Specified Length<br />

RL1500 Stock Length 2<br />

Accuracy Class<br />

H High Grade<br />

P Precision Grade<br />

U Ultra Precision Grade<br />

<strong>Rail</strong> Style<br />

A Standard<br />

U Bolt up from Bottom<br />

C Cover Strip<br />

4<br />

15<br />

20<br />

25<br />

Size<br />

30<br />

35<br />

45<br />

Corrosion-resistant option<br />

D Duralloy ® (H and P accuracy only)<br />

5<br />

S Stainless Steel Material<br />

Machined Options<br />

DH1 6mm Dowel Hole + Slot<br />

DH2 10mm Dowel Hole + Slot<br />

DH3 1⁄4” Dowel Hole + Slot<br />

DH4 3⁄8” Dowel Hole + Slot<br />

JT 3 Butt Joint<br />

E Bellow Clips Attached<br />

Specials<br />

SM Special Per Customer Print<br />

1. Y = Distance from end of rail to center of first mounting hole,<br />

Y1 = Y2 unless specified<br />

2. Stock length rails are considered random length, total length may<br />

exceed specified length, and Y1/Y2 are not equal. To be used by<br />

customer who will cut to length.<br />

3. Customer drawing required at time of quote and order.<br />

See page 130 for more information and templates.<br />

4. Cover strip rail available in size 25 and up only.<br />

5. Available in sizes 15 and 20 only. Max. rail length at 1,000mm.<br />

Ball Accessories<br />

5 3 1 WR<br />

15<br />

Type<br />

1 Ball<br />

500 Series<br />

<strong>Profile</strong> <strong>Rail</strong><br />

Product Type<br />

3 Accessory<br />

15<br />

20<br />

25<br />

Size<br />

30<br />

35<br />

45<br />

Bellows<br />

BB Low <strong>Profile</strong> Bellows 1<br />

BC High Compression Bellows 1<br />

BW Walk On Bellows 1<br />

CC Bellow clips for Carriage<br />

CR Bellow clips for <strong>Rail</strong><br />

<strong>Rail</strong> Hole Covers or Plugs<br />

HP Plastic <strong>Rail</strong> Plugs<br />

RT Mylar <strong>Rail</strong> Tape<br />

RCS <strong>Rail</strong> Cover Strip 1 2<br />

RCT <strong>Rail</strong> Cover Strip Installation Tool<br />

RCP <strong>Rail</strong> Cover End Cap<br />

Modular Seal Accessories 2<br />

WR Rubber Wiper<br />

VR Viton ® Wiper<br />

ZZ Metal Scraper<br />

OW Oil Reservoir<br />

LL Lube Block<br />

LS<br />

K<br />

Replacement Spring for LL Option<br />

Low Drag Seal<br />

Mounting Assembly Tools<br />

MT Mounting <strong>Rail</strong><br />

1. Bellows and rail cover strip must include length at time of order.<br />

Example: 531BB15 + 1000mm. See page 128 on how to calculate<br />

bellows length.<br />

2. Cover strip rail available in size 25 and up only.<br />

3. Two standard screws included with each item. Screws for attaching<br />

this accessory to carriage and not combinations of accessories.<br />

20<br />

www.thomsonlinear.com

J<br />

500 Series Ball<br />

B<br />

<strong>Profile</strong> <strong>Rail</strong> <strong>Linear</strong> <strong>Guides</strong><br />

500 Series Ball<br />

<strong>Profile</strong> <strong>Rail</strong><br />

511 / 513 Style A and B<br />

Reference Edge<br />

P<br />

O<br />

45<br />

M 1<br />

F 3<br />

F 3<br />

S 2 (From top)<br />

E<br />

F F<br />

G 1<br />

G 2<br />

J G 1<br />

A<br />

J 1<br />

G 2<br />

Y<br />

X<br />

F 2<br />

S3 Screw<br />

Size<br />

S 1 (From bottom)<br />

F 1<br />

B 2<br />

B 1<br />

511 / 513<br />

Style A<br />

Part Number<br />

Location<br />

Length<br />

L 2<br />

N<br />

L 1<br />

Y 2<br />

L 3 X Y 1<br />

L<br />

L 1<br />

511 / 513<br />

Style B<br />

L 2<br />

L 3<br />

L<br />

511 / 513 † Style A – Standard Ball<br />

Size Dimensions (mm) Ball<br />

A B B 1 * B 2 J J 1 L L 1 L 2 L 3 X N S 1 S 2 S 3 F F 1 F 2 F 3 Ø G G 1 G 2 M 1 O P<br />

+0.4 ±0.05<br />

–0.0<br />

15 24 47 15 16 20.2 15.7 56.6 30 26 39.6 60 38 M 4 M 5 M 4 4.4 4.5 8 7.5 3.2 7 4.5 9.5 4 7 7<br />

20 30 63 20 21.5 25.5 19 71.5 40 35 49.5 60 53 M 5 M 6 M 5 5.4 5.8 10 9.5 40 8 6.5 11.5 5.2 8 8<br />

25 36 70 23 23.5 30.5 22.7 84.5 45 40 59.5 60 57 M 6 M 8 M 6 6.8 7 11 11 4.8 9 8 14 5.5 7 11<br />

30 42 90 28 31 35.9 26 97.4 52 44 69.4 80 72 M 8 M 10 M 8 8.5 9 15 15 5.6 12 10 14.5 7 8 12<br />

35 48 100 34 33 41 29.5 111.6 62 52 79.6 80 82 M 8 M 10 M 8 8.5 9 15 15 6.4 12 12 18 7 8 14<br />

45 60 120 45 37.5 50.8 37 137.1 80 60 99.1 105 100 M 10 M 12 M 12 10.5 14 20 18 7.9 15 15 22 8 10 17.5<br />

511 / 513 † Style B – Standard Long Ball<br />

Size Dimensions (mm) Ball<br />

A B B 1 * B 2 J J 1 L L 1 L 2 L 3 X N S 1 S 2 S 3 F F 1 F 2 F 3 Ø G G 1 G 2 M 1 O P<br />

+0.4 ±0.05<br />

–0.0<br />

20 30 63 20 21.5 25.5 19 87.5 40 35 65.5 60 53 M 6 M 6 M 5 5.4 5.8 10 9.5 4.0 8 6.5 11.5 5.2 8 8<br />

25 36 70 23 23.5 30.5 22.7 103.5 45 40 78.5 60 57 M 8 M 8 M 6 6.8 7 11 11 4.8 9 8 14 5.5 7 11<br />

30 42 90 28 31 35.9 26 119.4 52 44 91.4 80 72 M 10 M 10 M 8 8.5 9 15 15 5.6 12 10 14.5 7 8 12<br />

35 48 100 34 33 41 29.5 137.1 62 52 105.1 80 82 M 10 M 10 M 8 8.5 9 15 15 6.4 12 12 18 7 8 14<br />

45 60 120 45 37.5 50.8 37 168.6 80 60 130.6 105 100 M 12 M 12 M 12 10.5 14 20 18 7.9 15 15 22 8 10 17.5<br />

* Standard tolerance shown, special lower tolerances are available upon request. Please consult application engineering for additional information.<br />

† 513 Spacer ball not available in size 15.<br />

www.thomsonlinear.com 21

<strong>Linear</strong> Motion. Optimized.<br />

500 Series Ball<br />

511 Style A and B<br />

Dynamic Load and Moment Ratings<br />

C = Dynamic load rating<br />

M P = Dynamic pitch and yaw moment rating<br />

M R = Dynamic roll moment rating<br />

Static Load and Moment Ratings<br />

C O = Static load rating<br />

M OP = Static pitch and yaw moment rating<br />

M OR = Static roll moment rating<br />

M P /M OP<br />

C<br />

C O<br />

M P /M OP<br />

M R /M OR<br />

Roll<br />

Pitch<br />

C/C O C/C O<br />

Yaw<br />

511<br />

Style<br />

A<br />

B<br />

Size<br />

15<br />

C O<br />

(N)<br />

Static<br />

M OR<br />

(Nm)<br />

M OP, OY<br />

(Nm)<br />

C<br />

(N)<br />

Load Rating<br />

M R<br />

(Nm)<br />

M P,Y<br />

(Nm)<br />

19 600 181 146 9 000 83 67<br />

Dynamic<br />

100 Km 50 Km<br />

C<br />

(N)<br />

M R<br />

(Nm)<br />

M P, Y<br />

(Nm)<br />

Carriage<br />

(kg)<br />

Weights<br />

(kg/m)<br />

11 339 105 84 0.2 1.4<br />

15-S 19 600 181 146 7 600 70 57 9 576 88 106 0.2 1.4<br />

20 31 400 373 292 14 400 171 134 18 143 215 169 0.5 2.2<br />

20-S 31 400 373 292 12 000 143 112 15 120 180 141 0.5 2.2<br />

25 46 100 631 513 21 100 289 235 26 584 364 296 0.7 3.0<br />

30 63 700 1 084 829 29 200 497 380 36 790 626 479 1.2 4.3<br />

35 84 400 1 566 1 252 38 700 718 574 48 759 905 723 1.8 5.4<br />

45 134 800 3 193 2 498 61 900 1 466 1 147 77 989 1 847 1 445 3.3 8.8<br />

20 41 100 490 495 17 400 206 208 21 923 260 262 0.6 2.2<br />

25<br />

60 300 825 863 25 500 349 365<br />

<strong>Rail</strong><br />

32 128 440 460 0.9 3.0<br />

30 83 300 1 414 1 390 35 300 599 589 44 475 755 742 1.5 4.3<br />

35 110 300 2 048 2 104 46 700 867 891 58 838 1 092 1 123 2.3 5.4<br />

45 176 300 4 175 4 199 74 700 1 769 1 779 94 116 2 229 2 241 4.2 8.8<br />

1. The dynamic load and moment ratings are based on the travel life<br />

specified on the table (100 km or 50 km). When comparing these<br />

load ratings with other bearings you must take into consideration<br />

the proper travel life basis.<br />

2. The static load and moment ratings are the maximum radial load<br />

and moment load that should be applied to the bearing when there<br />

is no relative motion between the carriage and the rail.<br />

3. For 513 Ball Spacer load ratings, contact Danaher Motion<br />

Application Engineering.<br />

Bearing Travel Life Comparison<br />

L = (C/F) 3 x 100km<br />

where:<br />

L = travel life, km<br />

C = 100 km dynamic load rating<br />

F = applied dynamic load, N<br />

1⁄ 3<br />

100<br />

C min = F L<br />

( )<br />

where:<br />

Cmin = minimum required<br />

dynamic load rating, N<br />

F = applied dynamic load, N<br />

L = required travel life, km<br />

Operating Parameters:<br />

Maximum Velocity: 5 m/s<br />

Maximum Acceleration: 100 m/s 2<br />

Temperature: Min: – 40° C<br />

Max: 80° C<br />

Max peak: 120° C short time*<br />

*without bellows<br />

Conversion Factors: See Page 130<br />

22<br />

www.thomsonlinear.com

J<br />

500 Series Ball <strong>Profile</strong> <strong>Rail</strong> <strong>Linear</strong> Guide<br />

<strong>Profile</strong> <strong>Rail</strong> <strong>Linear</strong> <strong>Guides</strong><br />

500 Series Ball<br />

<strong>Profile</strong> <strong>Rail</strong><br />

511 / 513 Style C and D<br />

Reference Edge<br />

M1<br />

O<br />

B<br />

Y<br />

X<br />

F 2<br />

S3 Screw<br />

Size<br />

S 2<br />

J 1<br />

F 1<br />

G 2<br />

J 1<br />

G<br />

A<br />

G 2<br />

B 2<br />

B 1<br />

511 / 513<br />

Style C<br />

N<br />

Y1<br />

X<br />

511 / 513<br />

Style D<br />

Part Number<br />

Location<br />

Y2<br />

L 1<br />

L 3<br />

Length<br />

L<br />

L 1<br />

L 3<br />

L<br />

N<br />

511 / 513 † Style C Narrow<br />

Size Dimensions (mm)<br />

A B B 1 * B 2 J J 1 L L 1 L 3 X N S 2 /S 3 F 1 F 2<br />

Ball<br />

Ø G G 2 M 1 O<br />

+0.4 +0.05<br />

– 0.0<br />

15 24 34 15 9.5 20.2 15.7 56.6 26 39.6 60 26 M 4 4.5 8 3.2 5 9.5 4 5.5<br />

20 30 44 20 12 25.5 19 71.5 36 49.5 60 32 M 5 5.8 10 4.0 7 11.5 5.2 6<br />

25 36 48 23 12.5 30.5 22.7 84.5 35 59.5 60 35 M 6 7 11 4.8 9 14 5.5 7.5<br />

30 42 60 28 16 35.9 26 97.4 40 69.4 80 40 M 8 9 15 5.6 11 14.5 7 8<br />

35 48 70 34 18 41 29.5 111.6 50 79.6 80 50 M 8 9 15 6.4 12 18 7 8<br />

511 / 513 † Style D Narrow Long<br />

Size Dimensions (mm)<br />

A B B 1 * B 2 J J 1 L L 1 L 3 X N S 2 /S 3 F 1 F 2<br />

Ball<br />

Ø G G 2 M 1 O<br />

+0.4 +0.05<br />

– 0.0<br />

20 30 44 20 12 25.5 19 87.5 50 65.5 69.5 32 M 5 5.8 10 4.0 7 11.5 5.2 6<br />

25 36 48 23 12.5 30.5 22.7 103.5 50 78.5 60 35 M 6 7 11 4.8 9 14 5.5 7.5<br />

30 42 60 28 16 35.9 26 119.4 60 91.4 80 40 M 8 9 15 5.6 11 14.5 7 8<br />

35 48 70 34 18 41 29.5 137.1 72 105.1 80 50 M 8 9 15 6.4 12 18 7 8<br />

* Standard tolerance shown, special lower tolerances are available upon request. Please consult application engineering for additional information.<br />

† 513 Spacer ball not available in size 15.<br />

www.thomsonlinear.com 23

<strong>Linear</strong> Motion. Optimized.<br />

<strong>Profile</strong> <strong>Rail</strong> <strong>Linear</strong> <strong>Guides</strong><br />

500 Series Ball<br />

511 Style C and D<br />

Dynamic Load and Moment Ratings<br />

C = Dynamic load rating<br />

M P = Dynamic pitch and yaw moment rating<br />

M R = Dynamic roll moment rating<br />

Static Load and Moment Ratings<br />

C O = Static load rating<br />

M OP = Static pitch and yaw moment rating<br />

M OR = Static roll moment rating<br />

C<br />

C O<br />

M R /M OR<br />

Roll<br />

C/C O C/C O<br />

M P /M OP<br />

Pitch<br />

M P /M OP<br />

Yaw<br />

511<br />

Style<br />

C<br />

Size<br />

15<br />

C O<br />

(N)<br />

Static<br />

M OR<br />

(Nm)<br />

M OP, OY<br />

(Nm)<br />

C<br />

(N)<br />

19 600 181 146 9 000 83 67<br />

Load Rating<br />

Dynamic<br />

100 Km 50 Km<br />

M R<br />

(Nm)<br />

M P,Y<br />

(Nm)<br />

C<br />

(N)<br />

M R<br />

(Nm)<br />

M P, Y<br />

(Nm)<br />

Carriage<br />

(kg)<br />

Weights<br />

(kg/m)<br />

11 339 105 84 0.2 1.4<br />

15-S 19 600 181 146 7 600 70 57 9 576 88 106 0.2 1.4<br />

20 31 400 373 292 14 400 171 134 18 143 215 169 0.5 2.2<br />

20-S 31 400 373 292 12 000 143 112 15 120 180 141 0.5 2.2<br />

25 46 100 631 513 21 100 289 235 26 584 364 296 0.7 3.0<br />

30 63 700 1 084 829 29 200 497 380 36 790 626 479 1.2 4.3<br />

<strong>Rail</strong><br />

35 84 400 1 566 1 252 38 700 718 574 48 759 905 723 1.8 5.4<br />

20 41 100 490 495 17 400 206 208 21 923 260 262 0.6 2.2<br />

D<br />

25<br />

60 300 825 863 25 500 349 365<br />

32 128 440 460 0.9 3.0<br />

30 83 300 1 414 1 390 35 300 599 589 44 475 755 742 1.5 4.3<br />

35 110 300 2 048 2 104 46 700 867 891 58 838 1 092 1 123 2.3 5.4<br />

1. The dynamic load and moment ratings are based on the travel life<br />

specified on the table (100 km or 50 km). When comparing these<br />

load ratings with other bearings you must take into consideration<br />

the proper travel life basis.<br />

2. The static load and moment ratings are the maximum radial load<br />

and moment load that should be applied to the bearing when there<br />

is no relative motion between the carriage and the rail.<br />

3. For 513 Ball Spacer load ratings, contact Danaher Motion<br />

Application Engineering.<br />

Bearing Travel Life Comparison<br />

L = (C/F) 3 x 100 km<br />

where:<br />

L = travel life, km<br />

C = 100 km dynamic load rating<br />

F = applied dynamic load, N<br />

1⁄ 3<br />

100<br />

C min = F L<br />

( )<br />

where:<br />

C min = minimum required<br />

dynamic load rating, N<br />

F = applied dynamic load, N<br />

L = required travel life, km<br />

Operating Parameters:<br />

Maximum Velocity: 5 m/s<br />

Maximum Acceleration: 100 m/s 2<br />

Temperature: Min: – 40° C<br />

Max: 80° C<br />

Max peak: 120° C short time*<br />

*without bellows<br />

Conversion Factors: See Page 132<br />

24<br />

www.thomsonlinear.com

J<br />

500 Series Ball <strong>Profile</strong> <strong>Rail</strong> <strong>Linear</strong> Guide<br />

<strong>Profile</strong> <strong>Rail</strong> <strong>Linear</strong> <strong>Guides</strong><br />

500 Series Ball<br />

<strong>Profile</strong> <strong>Rail</strong><br />

511 / 513 Style E and F<br />

Reference Edge<br />

M 1<br />

O<br />

B<br />

S 2<br />

G<br />

J 1<br />

A<br />

J 1<br />

G 2<br />

Y<br />

X<br />

F 2<br />

S3 Screw<br />

Size<br />

G 2<br />

F 1<br />

B 2<br />

B1<br />

511 / 513<br />

Style E<br />

N<br />

X Y 1<br />

511 / 513<br />

Style F<br />

Part Number<br />

Location<br />

L 1<br />

L 3<br />

Y 2<br />

L<br />

Length<br />

L 1<br />

L 3<br />

L<br />

N<br />

511 / 513 † Style E Narrow High<br />

Size Dimensions (mm) Ball<br />

A B B 1 * B 2 J J 1 L L 1 L 3 X N S 2 /S 3 F 1 F 2 Ø<br />

+0.4 +0.05<br />

G G 2 M 1 O<br />

-0.0<br />

15 28 34 15 9.5 24.2 15.7 56.6 26 39.6 60 26 M 4 4.5 8 3.2 6 9.5 8 6<br />

25 40 48 23 12.5 34.5 22.7 84.5 35 59.5 60 35 M 6 7 11 4.8 9 14 9.5 11<br />

30 45 60 28 16 38.9 26 97.4 40 69.4 80 40 M 8 9 15 5.6 11 14.5 10 11<br />

35 55 70 34 18 48 29.5 111.6 50 79.6 80 50 M 8 9 15 6.4 12 18 14 15<br />

45 70 86 45 20.5 60.8 37 137.1 60 99.1 105 60 M 10 14 20 7.9 18 22 18 19<br />

511 / 513 † Style F Narrow Long High<br />

Size Dimensions (mm) Ball<br />

A B B 1 * B 2 J J 1 L L 1 L 3 X N S 2 /S 3 F 1 F 2 Ø<br />

+0.4 +0.05<br />

G G 2 M 1 O<br />

-0.0<br />

25 40 48 23 12.5 34.5 22.7 103.5 50 78.5 60 35 M 6 7 11 4.8 9 14 9.5 11<br />

30 45 60 28 16 38.9 26 119.4 60 91.4 80 40 M 8 9 15 5.6 11 14.5 10 11<br />

35 55 70 34 18 48 29.5 137.1 72 105.1 80 50 M 8 9 15 6.4 12 18 14 15<br />

45 70 86 45 20.5 60.8 37 168.6 80 130.6 105 60 M 10 14 20 7.9 18 22 18 19<br />

* Standard tolerance shown, special lower tolerances are available upon request. Please consult application engineering for additional information.<br />

† 513 Spacer ball not available in size 15.<br />

www.thomsonlinear.com 25

<strong>Linear</strong> Motion. Optimized.<br />

<strong>Profile</strong> <strong>Rail</strong> <strong>Linear</strong> <strong>Guides</strong><br />

500 Series Ball<br />

511 Style E and F<br />

Dynamic Load and Moment Ratings<br />

C = Dynamic load rating<br />

M P = Dynamic pitch and yaw moment rating<br />

M R = Dynamic roll moment rating<br />

Static Load and Moment Ratings<br />

C O = Static load rating<br />

M OP = Static pitch and yaw moment rating<br />

M OR = Static roll moment rating<br />

C<br />

C O<br />

M R /M OR<br />

Roll<br />

C/C O C/C O<br />

M P /M OP<br />

Pitch<br />

M p /M OP<br />

Yaw<br />

511<br />

Style<br />

E<br />

F<br />

Size<br />

15<br />

C O<br />

(N)<br />

Static<br />

M OR<br />

(Nm)<br />

M OP, OY<br />

(Nm)<br />

C<br />

(N)<br />

M R<br />

(Nm)<br />

M P,Y<br />

(Nm)<br />

19 600 181 146 9 000 83 67<br />

Load Rating<br />

Dynamic<br />

100 Km 50 Km<br />

C<br />

(N)<br />

M R<br />

(Nm)<br />

M P, Y<br />

(Nm)<br />