July-August 2011 - Aeromag

July-August 2011 - Aeromag

July-August 2011 - Aeromag

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

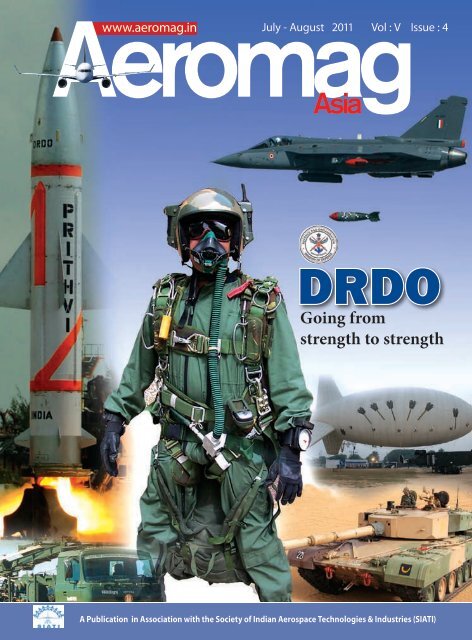

<strong>Aeromag</strong><br />

www.aeromag.in<br />

<strong>July</strong> - <strong>August</strong> <strong>2011</strong> Vol : V Issue : 4<br />

Asia<br />

DRDO<br />

Going from<br />

strength to strength<br />

A Publication in Association with the Society of Indian Aerospace Technologies & Industries (SIATI)

Reliable<br />

IS THE LACK OF A SYSTEMS INTEGRATOR<br />

^ GIVING YOU A MIGRAINE<br />

Harness Captronics’ Expertise & Experience in System Integration!<br />

At Captronic Systems we make the leap from SAYING TO DOING<br />

AEROSPACE<br />

DEFENCE<br />

TIME IS MONEY.<br />

GET MORE OF BOT H .<br />

AUTOMOTIVE<br />

NUCLEAR<br />

UNIT UNDER TEST<br />

POWER<br />

MANUFACTURING<br />

WHO ARE WE<br />

A dynamic Systems Integrator, Captronic Systems Pvt Ltd started in<br />

1999 as the bridge between Technology & Application. We specialize in<br />

the design and development of custom ATE’s with over 450 ATE’s<br />

installed worldwide, six branch offices in India and two overseas,<br />

namely UAE & USA. Over 80 LabVIEW certified engineers.<br />

AUTOMATION & TEST EQUIPMENT SPECIALISTS<br />

WHAT DO WE DO<br />

We provide Effective, Efficient, Enterprising and Economic Solutions for<br />

all your System Integrator needs in the areas of AEROSPACE, DEFENCE,<br />

AUTOMOTIVE, MANUFACTURING, NUCLEAR and POWER SECTOR<br />

CERTIFIED<br />

No.3, Victorian Meadows, Airport Varthur Road, Marathalli P.O., Bangalore, India 560037<br />

Ph: +91-80-40373900, Fax: +91-80-40373839 Email: barry@captronicsystems.com www.captronicsystems.com<br />

DELHI HYDERABAD TRIVANDRUM CHENNAI PUNE MUMBAI UAE USA<br />

SELECT ALLIANCE PARTNER<br />

ECO CNC<br />

Make a lot more parts in a lot less time with a high-performance<br />

Haas Drill/Tap Center. The DT-1 swaps tools in 0.8 seconds, and its<br />

12,000-rpm spindle allows rigid tapping to 5000 rpm, with up to 4-times<br />

retract speed. And, 2400 ipm rapids and 1 G accelerations combine to<br />

reduce cycle times even further. All this – for a great price.<br />

Typical Haas Ingenuity.<br />

Haas Automation<br />

Simple. Innovation.<br />

Haas Factory Outlet – India locations<br />

NORTH, WEST AND EAST AREAS: telephone – 022-27742181, 9320178231<br />

SOUTH AREAS: telephone – 080-41179452 / 53<br />

Email: indiasales@haascnc.com | www.HaasCNC.com | Made in the USA

A e r o m a g 4<br />

A e r o m a g 5

<strong>Aeromag</strong><br />

Asia<br />

A Bimonthly Publication<br />

Dedicated to<br />

Aviation & Aerospace Industry<br />

Editorial Advisory Board<br />

Dr. C.G.Krishnadas Nair,<br />

Air Chief Marshal S.Krishnaswamy (Rtd)<br />

PVSM, AVSM, VM & Bar<br />

Air Marshal P. Rajkumar (Rtd)<br />

PVSM, AVSM, VM<br />

Air Marshal Ajit Bhavanani (Rtd)<br />

PVSM, AVSM, VM<br />

Rear Admiral K. Mohanan (Rtd)<br />

AVSM<br />

Mr. Pushpindar Singh Chopra<br />

Dr . K. Ram Chand<br />

Mr. J.K.Sharma<br />

Mr. Arunakar Mishra<br />

Air Cmdre. (Rtd) Joseph Varkey<br />

Delhi<br />

Gp. Capt. (Rtd) H.C.Bhatia<br />

Secretary , AeSi<br />

Ashok Iyer<br />

E-mail : ashok.iyer@aeromag.in<br />

Mobile : + 91 9811831199<br />

Bombay<br />

P. A. <strong>August</strong>ine<br />

Email : info@aeromag.in<br />

Germany<br />

Detlef Becker<br />

Email : dw.becker@arcor.de<br />

Phone : + 497 112317595<br />

Mobile : + 491 701626053<br />

New York<br />

Joseph J<br />

Email : info@aeromag.in<br />

Dubai<br />

Rajan Joseph<br />

E mail : info@aeromag.in<br />

London<br />

Naresh Mohan Yadav<br />

Tel : + 44 208 989 1110<br />

ADVERTISEMENTS :<br />

Tel : + 91 80 25284145 / 65952377<br />

Mobile : + 9194490 61925<br />

Email : info@aeromag.in<br />

Website : www.aeromag.in<br />

Aviation safety – An issue<br />

of paramount importance<br />

Air traffic in India has bounced back<br />

after a mild recession during the<br />

global economic slowdown, and<br />

is expected to grow in the current decade<br />

at a healthy 15 per cent per year. Domestic<br />

and international passenger traffic are<br />

projected to grow well beyond 500 million<br />

by 2020. Several regional airports are being<br />

upgraded and new ones built.<br />

With this impressive growth, focus also<br />

needs to be on aviation safety both on<br />

ground and air in no small measure. Safety<br />

audit has been made mandatory in all airports and special counters have<br />

also been introduced in many places for flight safety, airport safety and<br />

also passenger safety. But there is little doubt that strict implementation<br />

and enforcement is key and we need to redouble our efforts towards<br />

completely curbing any mishaps.<br />

Though a lot of new technologies are available to prevent Aviation<br />

safety hazards, interest levels need to go up several notches in India. Every<br />

year accidents involving bird hits on aircraft are increasing in addition to<br />

mishaps on the ground. In 2010, there were 372 incidents compared to 302<br />

in the previous year in Indian Airports according to DGCA statistics.<br />

In order to give an in-depth insight into Avition safety hazards and new<br />

technologies available to meet these kinds of mishaps, <strong>Aeromag</strong> Asia with<br />

the support of SIATI, Indian Air Force and other Aerospace organisations<br />

will organise the third international seminar during December first week<br />

in New Delhi.<br />

All stake-holders in this sector in India, Airlines, Airports, Ground handling<br />

Agencies, Pilots, Ornithologists, Aviation and Airport security companies,<br />

Aircraft and Aero Engine manufacturers, are expected to actively<br />

participate in this seminar. It will also be a great opportunity for overseas<br />

organisations specialising in Airport Safety, Aviation and Flight Safety, Fire<br />

Safety and Bird control to get associated with.<br />

Let us work together to build a strong foundation for Aviation Safety in<br />

India.<br />

Warmly,<br />

Dr CG Krishnadas Nair<br />

Honorary President, SIATI<br />

Printed and Published by Sunny Jerome, Managing Editor, <strong>Aeromag</strong> Asia, Aerosun Media Pvt. Ltd. B-2, SAPPHIRE, 1 st Block, 3 rd Street, 2nd Cross,<br />

Prakruthi Town Ship, Babusapalya, Kalyan Nagar Post, Bangalore -560043. Phone + 91 80 25284145<br />

Printed at Rashtrotthana Mudranalaya, 19/1, K.G.Nagar, Bangalore-19.<br />

Page 18<br />

Golden era for India in defence<br />

technology arena: Dr. Prahlada<br />

Page 20<br />

MIDHANI may set<br />

up second plant to<br />

meet booming demand<br />

Page 22<br />

Will grow rapidly in India, says<br />

Honeywell<br />

Page 26<br />

Haas India announces inaugural<br />

HaasTEC Open House<br />

Page 28<br />

Morpho unveils vision for aviation<br />

security solutions<br />

Page 32<br />

MathWorks working with<br />

academia as partnership<br />

Page 36<br />

HAL plans four new<br />

manufacturing plants<br />

Contents<br />

DRDO<br />

Going from<br />

strength to strength<br />

47<br />

T-50 stealth fighter<br />

makes public debut<br />

38<br />

Aerospace<br />

Engineers take up<br />

new endeavours<br />

Real-Time and Historical Situational<br />

Awareness of Birds with Avian Radar<br />

52<br />

Need 50 % stake<br />

for future venture<br />

in India, says<br />

Rafael<br />

12<br />

40<br />

A e r o m a g 6<br />

A e r o m a g 7

India poised<br />

to become world’s third<br />

largest civil aviation market<br />

India is currently celebrating<br />

the completion of 100 years of<br />

commercial civil aviation in this<br />

country. A hundred years ago, a plane<br />

flew from Allahabad to Naini, carrying<br />

6500 mails. This marked not only the<br />

birth of commercial civil aviation in<br />

India but also the first airmail service in<br />

the world.<br />

India took to wings only seven years<br />

after the historic flight of the Wright<br />

brothers. It is believed that the first<br />

planes came to India and perhaps to<br />

Asia in 1910 though the first commercial<br />

civil aviation flight took off only on the<br />

18th February 1911.<br />

Since then India and Indians have<br />

never looked back. Through the<br />

eventful decades, Indian civil aviation<br />

has flown from strength to strength<br />

and is today one of the fastest growing<br />

aviation market in the world.<br />

Contributing to this growth has been the<br />

undoubting spirit of India’s entrepreneurs,<br />

pilots, engineers, crew-members and<br />

scientists.<br />

Civil aviation is a major driver of the<br />

economy. The International Civil Aviation<br />

Organisation estimates that every 100<br />

dollars spent on air transport produce<br />

benefits worth 325 dollars for the<br />

economy. Hundred additional jobs in air<br />

transport result in 610 new jobs in the<br />

economy.<br />

Exponential expansion<br />

The last hundred years have seen Indian<br />

civil aviation expand exponentially. From<br />

the days of the first flight when aircrafts<br />

landed on plain grounds without any<br />

navigational aids, India has traveled a<br />

long distance to modern and world-class<br />

airports of Hyderabad, Cochin, Bangalore<br />

and of course T-3.<br />

Today the handling capacity of India’s<br />

airports has reached to 235 million people,<br />

which is sufficient to fulfill its needs for<br />

the next few years. Airports are being<br />

improved not only in the major Metros but<br />

also 35 non-Metros, in a phased manner.<br />

During the last two decades from a<br />

fleet of only about 100, the scheduled<br />

operators today have 435 aircraft<br />

connecting the nation and the world. This<br />

growth is going to be further accelerated<br />

in the years to come and the government<br />

expects that in another decade or so India<br />

would have about 1000 more planes and<br />

500 more helicopters.<br />

The acquisition of these modern aircraft<br />

and the investment in airports is expected<br />

to generate business opportunities<br />

worth about 150 billion dollars that will<br />

revolutionize the sector. Civil Aviation is<br />

clearly the sunrise sector of the Indian<br />

economy that is likely to change the way<br />

Indians move, think and live.<br />

The last hundred years have posed<br />

innumerable challenges in the civil<br />

aviation sector which India successfully<br />

overcame. The new century that lies<br />

ahead of it, is also bound to throw up new<br />

challenges. It is necessary for India, as a<br />

nation, to foresee those challenges and to<br />

prepare itself to meet them effectively.<br />

One of the safest countries<br />

The increase in the number of aircraft<br />

is bound to put a heavy pressure on<br />

India’s regulatory and oversight systems.<br />

Today India is considered to be one<br />

of the safest countries in terms of civil<br />

aviation. Recently, the Federal Aviation<br />

Administration (FAA) of America even<br />

cited India as a role model in the Asia-<br />

Pacific region.<br />

In order to retain this position and to<br />

assure all travelers the guarantee of safety,<br />

it would be necessary to redefine the<br />

parameters of regulation. Government<br />

is already looking into this matter and<br />

considering restructuring of the DGCA<br />

into a more comprehensive system, which<br />

works well above international standards.<br />

One of the biggest challenges before<br />

India is to lend renewed vibrancy to<br />

public sector undertakings like Air India<br />

and Airports Authority of India. These<br />

two organizations have rendered historic<br />

service to the nation and their continued<br />

vibrancy is critical for optimal growth of<br />

the sector. The Government is committed<br />

to support these organizations to ensure<br />

their healthy future. Civil aviation is a<br />

major employment creator and according<br />

to available studies it is expected that<br />

this sector will create new employment<br />

opportunities for nearly 26 lakh Indians by<br />

2025.<br />

Catering to this human resource need is<br />

in itself a challenge. India needs to strive<br />

to develop and nurture a strong world<br />

class training infrastructure in the country<br />

to ensure continuous production of skilled<br />

and professional manpower to fulfill the<br />

requirements of this sector.<br />

Sensitive to economic environment<br />

Civil Aviation industry is extremely<br />

sensitive to the economic environment<br />

in which it operates. Issues of taxation,<br />

investment policies and competition are<br />

vital to its survival. As the sector grows,<br />

there would be an acute need to fine-tune<br />

our system of competition management,<br />

taxation laws and investment strategies,<br />

while remaining socially responsible<br />

towards the aspirations of common<br />

Indians. The increase in civil aviation<br />

activity is bound to impact the<br />

environment too. It is necessary that<br />

India should nationally gear up to face<br />

this challenge and move towards better<br />

technologies and mitigation strategies<br />

to minimize the effect of aviation on<br />

environment. A socially harmonized<br />

growth of aviation alone will ensure its<br />

sustainability.<br />

While India is celebrating its continuous<br />

growth it is also necessary to be eternally<br />

cautious of the threats to its security from<br />

various quarters. It has to remember the<br />

tragedies of Kanishka and IC 814 to remain<br />

constantly vigilant of the dangers that lurk<br />

round the corner.<br />

Security is top priority<br />

Maintaining security is the priority that<br />

cannot be overlooked even for a single<br />

moment. It might have some effect on<br />

passenger facilitation but it is imperative<br />

in the larger interest of travelers as well as<br />

of the nation.<br />

Officials said Indian aviation sector is<br />

major economic driver for prosperity,<br />

development and employment and its<br />

airports today have become the symbol<br />

of India’s growth story.<br />

This sector with the growth of 18 per cent<br />

in domestic market is poised to emerge<br />

as the third largest aviation market in<br />

the world by the end of this decade.<br />

Huge potential in this sector is yet to be<br />

tapped and this is possible only with the<br />

cooperation and coordination among the<br />

partners; Centre, States and private sector.<br />

Issues of safety, security, infrastructure<br />

development and connectivity are most<br />

important in the aviation sector. There<br />

should be zero tolerance policy as far as<br />

safety is concerned.<br />

Security is indivisible and cannot be<br />

segregated between States and Centre.<br />

There is a need to harmonize the processes<br />

and procedures at all the Airports and to<br />

ensure that the State police staff is well<br />

trained and proficient in work as the CISF.<br />

Government’s role<br />

Government’s role in connectivity is<br />

limited to formulate socially equitable<br />

policies and ensure its implementation.<br />

The Civil Aviation ministry is considering<br />

restructuring the DGCA into a Civil<br />

Aviation Authority (CAA).<br />

In order to prevent repetitive accidents,<br />

an Independent Civil Aviation Accident<br />

Investigation Committee has been set<br />

up within oversight of Ministry of Civil<br />

Aviation to coordinate and oversee the<br />

investigation into accidents and also<br />

effective follow up of compliance of<br />

recommendations.<br />

Steps are under way to set up a<br />

full-fledged Independent Accident<br />

Investigation Board.<br />

A e r o m a g 8<br />

A e r o m a g 9

SCHUNK’s<br />

thrust on optimised solution<br />

SCHUNK is a leading player in the<br />

field of precision tool holding, work<br />

holding and automation technology<br />

of over 65 years. The experience has resulted<br />

in unique, productive and many a times,<br />

proprietary advantages and niche which has<br />

always been guided by the corner stones of<br />

customer centric advantage for which, the<br />

brand commands today, a premium position<br />

for its products and services. The valuable<br />

experience is evident with its wide choice<br />

of products “one for every application”.<br />

SCHUNK believes that every application is<br />

specific and selective that needs a much<br />

optimised solution rather than a generic<br />

one.<br />

PRISMO, the tool grinding toolholder, is<br />

now available with manual actuation. It is<br />

attached as a substructure to the PRISMO,<br />

and allows stationary application at<br />

cylindrical grinding machines, tool grinding<br />

machines or lathes. This innovative tool<br />

grinding toolholder clamps every shank<br />

diameter between 5 and 20 mm.<br />

The TENDO SVL tools with a shank<br />

diameter of 6 mm, can be directly clamped<br />

without the use of intermediate sleeves,<br />

making them highly precise. The TENDO<br />

SVL transforms almost every precision<br />

tool holder into a flexible tool, perfect to<br />

use in confined spaces. The high torque of<br />

the TENDO SVL ensures a safe hold of the<br />

tool during drilling, reaming and finish<br />

milling. Instead of expensive special tools,<br />

the use of a TENDO extension is normally<br />

enough, and it can be equipped with<br />

various standard tools as required.<br />

The ROTA NCL lightweight lathe<br />

chuck defines efficiency for turning<br />

operations. The ROTA NCL steel version<br />

weighs about 35 % less compared to<br />

conventional power chucks of the same<br />

size. Therefore faster acceleration at<br />

reduced energy consumption is possible.<br />

A new type of double cylinder guidance<br />

of the base jaws ensures that the forces<br />

are evenly distributed on the chuck<br />

body. With its large through-hole, the<br />

lathe chuck is almost maintenance-free,<br />

completely sealed and permanently<br />

lubricated, making it perfectly suitable<br />

for applications in modern machining<br />

centers. In addition to the 3-jaw version,<br />

the ROTA NCS also has a high-precision<br />

6-jaw chuck. During clamping of thinwalled<br />

and uneven components, the 6<br />

oscillating jaws ensure maximum run-out<br />

accuracy and minimum deformation at<br />

the work pieces. The 3-jaw power chuck<br />

type ROTA NCD is particularly well suited<br />

for users who machine several work<br />

pieces on one machine and can reduce<br />

set-up times and costs with the highperformance<br />

lathe chuck.<br />

ROTA NCL lathe chuck is hermetically<br />

sealed against dust and coolant, and is<br />

mostly maintenance-free. Its low height<br />

leaves plenty of space in the machine<br />

room. With the sizes 185, 225, and 260 the<br />

lathe chuck is universal in purpose, and<br />

clamping forces between 75 and 140 kN<br />

are achieved.<br />

Air Marshal N A K Browne<br />

is Chief of Air Staff<br />

Air Marshal N A K Browne has taken<br />

over as Chief of Air Staff.<br />

Born in Allahabad on 15<br />

December 1951, Air Marshal Browne was<br />

commissioned into the Fighter stream<br />

of Indian Air Force on 24 June 1972. With<br />

about 3100 hours of flying to his credit, he<br />

has had a varied operational experience<br />

that included flying Hunters, all variants of<br />

MiG-21s, Jaguars and SU-30s.<br />

An alumnus of National Defence<br />

Academy, Khadakwasla, Pune, he is a<br />

Fighter Combat Leader, who has also<br />

served as an instructor at the Tactics and<br />

Air Combat Development Establishment<br />

(TACDE) - a premiere flying establishment<br />

of the IAF and the Tri-services Defence<br />

Services Staff College (DSSC), Wellington.<br />

A graduate of the Air Command and<br />

Staff College, USA, he had trained with<br />

the Royal Air Force (RAF) in the United<br />

Kingdom, on Jaguar aircraft and went<br />

on to command a Jaguar Squadron<br />

subsequently.<br />

During his long and distinguished career<br />

spanning 38 years, he has held various<br />

operational and staff appointments<br />

that include - Joint Director at Air War<br />

Strategy Cell at Air Headquarters, Chief<br />

Operations Officer and Air Officer<br />

IAF to receive license to<br />

issue Digital Certificates<br />

The IAF took another significant<br />

step towards its net-centric vision,<br />

when the Chief of the Air Staff, Air<br />

Chief Marshal NAK Browne was formally<br />

handed over the license to issue Digital<br />

Signature Certificates by the Controller<br />

of Certifying Authorities (CCA), Dr N Vijay<br />

Aditya at Air Headquarters .<br />

As a part of the AFNET (Air Force<br />

Network) Project, Digital Signatures<br />

issued by a license holder would provide<br />

the legal recognition to an electronic<br />

The Chief of the Air Staff, Air Chief Marshal N.A.K. Browne receiving license to issue<br />

Digital Certificate from the Controller of Certifying Authorities (CCA), Dr. N. Vijay Aditya,<br />

in New Delhi<br />

Commanding of a SU-30 base, Air-I at<br />

New Delhi based Western Air Command<br />

(WAC) and Assistant Chief of the Air Staff<br />

(Intelligence) at Air Headquarters.<br />

He was also responsible for establishing<br />

the Indian Defence Wing in Tel Aviv, Israel<br />

in April 1997 where he served as the<br />

Defence Attache till <strong>July</strong> 2000. From March<br />

2007 to 31 May 2009 he functioned as the<br />

Deputy Chief of the Air Staff (DCAS) at Air<br />

Headquarters and was responsible for<br />

lAF’s major Modernization Programmes.<br />

Before taking over as the Vice Chief of<br />

the Air Staff (VCAS) at Air Headquarters<br />

on 01 January <strong>2011</strong>, he was the AOC-in-C<br />

of Western Air Command, lAF’s most vital<br />

operational Command. Under his command<br />

and personal supervision, the first ever<br />

landing of an AN-32 (fixed wing aircraft) took<br />

place at Nyoma, advance Landing Ground<br />

(ALG), located at an altitude of 13,300 feet<br />

on 18 September 2009.<br />

Air Marshal Browne is recipient of Param<br />

Vishist Seva Medal (PVSM), Ati Vishist Seva<br />

Medal (AVSM), Vayu Sena Medal (VM) and<br />

is appointed as one of the Honorary ADCs<br />

to the President of India.<br />

Married to Mrs Kiran Browne, they have<br />

a son, Omar, a fighter pilot in the IAF and<br />

a daughter Alisha, who is working with a<br />

multinational company.<br />

document under the IT Act 2000. With<br />

this, the IAF would be able to put in<br />

place a Public Key Infrastructure (PKI),<br />

which is a practical strategy for achieving<br />

information security in today’s highly<br />

networked environment. An essential<br />

component for providing enhanced<br />

Information Assurance and Identity<br />

Management Capabilities, PKI would<br />

provide data integrity, user identification<br />

and authentication, user non-repudiation,<br />

data confidentiality, encryption and<br />

digital signature services for programs<br />

and applications on Air Force Network.<br />

It would also issue and manage software<br />

and hardware certificates on the stateof-the-art<br />

IP/MPLS (Internet Protocol/<br />

Multiprotocol Label Switching) network of<br />

the IAF. With this system in place, the IAF<br />

becomes the first defence organization<br />

and the second Government body,[first<br />

being NIC (National Informatics Centre)]<br />

to receive the coveted license.<br />

Air Marshal KK Nowhar, Vice Chief of the<br />

Air Staff, Air Vice Marshal Sanjay Sharma,<br />

ACAS (Signals and IT), senior Air Force<br />

officials and luminaries from academia,<br />

private sector and public sector were<br />

among those who were present at the<br />

occasion.<br />

A e r o m a g 10<br />

A e r o m a g 11

DRDO<br />

Going from strength to strength<br />

DRDO has been flying higher with<br />

significant success in recent<br />

times. The surface-to-surface<br />

Prithvi (P-II) Missile was successfully flighttested<br />

at Launch Complex-III, Integrated<br />

Test Range (ITR), Chandipur, Balasore and<br />

Orissa, recently.<br />

Prithvi-II, the first indigenous surfaceto-surface<br />

strategic missile, capable of<br />

attacking targets at a range of 350 km,<br />

reaches the pre-defined target in the<br />

Bay of Bengal with a high accuracy of<br />

more than 10 m. All radars and electrooptical<br />

systems located along the coast<br />

monitored the flight path of the missile,<br />

and an Indian Naval ship located near the<br />

target.<br />

DRDO, in fact, has the vision to make<br />

India prosperous by establishing world<br />

class science, technology and systems<br />

engineering base and provide our Defence<br />

Services decisive edge by equipping them<br />

with internationally competitive systems<br />

and solutions.<br />

Agni, Prithvi, Akash! The three among<br />

five Panchtatva! However these names<br />

today, together with Tejas, Arjun,<br />

Dhanush, Varunastra, Sarvatra, Rohini,<br />

Bharani, Ashlesha, Samyukta, Sangraha,<br />

WLR (Weapon Locating Radar) among<br />

many others, symbolise the science,<br />

technology and system engineering<br />

strength of nation in the critical area of<br />

defence technology.<br />

DRDO had been the leader in the<br />

national effort along with its partners that<br />

include the armed forces, the industry and<br />

leading academic institutions.<br />

A giant organisation in its 54th year, i.e.<br />

DRDO, today is among the world’s largest<br />

and most diversified R&D institutions<br />

generating cutting edge technologies for<br />

reliable defence and credible deterrence<br />

against any potential misadventure. The<br />

innumerable obstacles to restrict India<br />

and DRDO in particular, in the field of<br />

various technology denial regimes by<br />

handful of technologically advanced<br />

nations, led to the DRDO scientists<br />

indigenously developing sophisticated<br />

weapon systems and technologies<br />

like Agni and Prithvi series of strategic<br />

missiles, Arjun- Main Battle Tank, Tejas-<br />

Light Combat Aircraft, nuclear powered<br />

submarine- Arihant, wide range of radar<br />

systems and electronic warfare systems.<br />

The DRDO has lived up to its tag line<br />

‘Balasya mulam vigyanam’ i.e. the source<br />

of strength is Science. It is Science that<br />

drives the nation in war and peace. DRDO<br />

has firm determination to make the nation<br />

strong and self reliant in terms of Science<br />

and Technology especially in the field of<br />

military.<br />

India now has the capability to develop<br />

any type of strategic missile. The Armed<br />

Forces now have Agni I (700 km), Agni II<br />

(2,000 km) and Agni III (3.500 km) in their<br />

arsenal. The DRDO now plans to test fire<br />

Agni-V by the year end and this missile<br />

enable hit targets at ranges of 5,000 km.<br />

The other missile systems now inducted<br />

into the Services include Prithvi (road<br />

mobile) and Dhanush (ship launched<br />

missile) series of surface-to-surface<br />

missiles. These nuclear capable platforms<br />

provide effective deterrence and credible<br />

second strike capability.<br />

An integrated life support system<br />

(ILSS) for fighter aircraft, a state of the art<br />

technology that enables the fighter pilot<br />

A e r o m a g 12<br />

A e r o m a g 13

to venture to the limits of the aircraft<br />

capability in terms of flight altitudes and<br />

G-forces. This technology had been the<br />

hallmarks of the few highly advanced<br />

countries. Now Defence Bioengineering<br />

& Electromedical Laboratory (DEBEL)<br />

Bangalore, under DRDO, has taken a lead<br />

in this technology that, to start with, will<br />

go into Tejas aircraft. The engineering<br />

model of ILSS prototype has been rolled<br />

out from DEBEL, Bangalore.<br />

The Infrastructural facilities created by<br />

DRDO are national assets and include<br />

Integrated Instrumented flight Test<br />

Range, Structural Dynamics & Vibration<br />

Test facility for aircraft, electronic warfare<br />

Test ranges, Propulsion and Ballistics test<br />

facilities, underwater Weapon Test Ranges<br />

and Test Tracks for land systems etc.<br />

DRDO’S LIMELIGHT<br />

DRDO has been focusing on futuristic<br />

technology development and a roadmap<br />

‘Defence Technology Vision 2050’ is being<br />

framed. The DRDO is presently working<br />

on designing a 1500 horsepower engine<br />

and artillery guns of 155 mm calibre’.<br />

In terms of tangible outputs, DRDO had<br />

developed a wide range of strategic and<br />

tactical weapon systems and complex<br />

technologies associated with such<br />

systems. The production value of major<br />

DRDO systems inducted/under induction<br />

into the three Services during the last<br />

decade stands at over Rs 1,20,000 Crores<br />

with a modest R&D investment of about<br />

Rs 3,000 Crores per year.<br />

The DRDO scientists did India proud by<br />

indigenously and successfully producing<br />

series of strategic missile systems like Agni<br />

(intermediate range ballistic missiles),<br />

Prithvi Dhanush and Shourya, covering<br />

wide range (150 km to 3500 km).<br />

The DRDO had also carried out series<br />

of successful trials of Air Defence System<br />

against ballistic missiles of up to 2000 km<br />

class, for both exo- atmospheric (80 km<br />

altitude) and endo- atmospheric (15 km<br />

altitude) interception.<br />

BrahMos supersonic cruise missile for<br />

Army and Navy is a glowing example of<br />

the first ever joint design and production<br />

of a weapon system by India and Russia.<br />

Today Indian armed forces are the only<br />

one in the world possessing a BrahMos<br />

class missile.<br />

The DRDO had indigenously designed,<br />

developed and led the production of Tejas<br />

Light Combat Aircraft (LCA). Ten Tejas<br />

aircraft have completed more than 1,650<br />

flights. The first naval variant of LCA has<br />

also rolled out and will equip our aircraft<br />

carriers. With the success of Nishant (short<br />

range) and Rustom-1 (medium endurance)<br />

UAVs (Unmanned Aerial Vehicle), it had<br />

demonstrated capability to design,<br />

develop and lead to the production of<br />

such platforms and various associated<br />

technologies, components and sub<br />

systems such as advanced structural<br />

composites, Flight Control Systems,<br />

Actuators, Sensors and so on.<br />

Two regiments of India’s first<br />

indigenously designed, developed and<br />

productionised Main Battle Tank “MBT-<br />

Arjun Mk-I” had been raised and inducted<br />

in the Army. With its excellent mobility<br />

& maneuverability especially in desert<br />

combined with state of the art armour<br />

and accurate firepower it is rightly called<br />

“king of desert”.<br />

The DRDO had attracted young<br />

students to take up defence, science and<br />

technology as career option. Competent<br />

manpower is inducted into DRDO through<br />

several schemes such as All India DRDO<br />

Scientist Entry Test (SET), Annual Campus<br />

Talent Search, induction of fresh PhD<br />

graduates, online selection fvor NRIs and<br />

selection of scientists under Lateral Entry<br />

Scheme.<br />

In addition to striving for accomplishment<br />

of goals, DRDO has undertaken several<br />

new technology initiatives in the areas of<br />

Cyber Security, Space Security, and Energy<br />

Security. In view of the growing threats<br />

of cyber attacks and data theft, there is<br />

a need to develop our own computer<br />

operating system so that the source code<br />

and complete architecture is known to<br />

it and any malicious attempts of cyber<br />

attacks are thwarted.<br />

There is a need to develop technologies<br />

for protection, detection, and mitigation<br />

of cyber threats. DRDO has launched<br />

projects covering development of<br />

indigenous operating systems, hardened<br />

network hardware, and network security<br />

devices. In the field of Space Security,<br />

it has launched programme for space<br />

surveillance and security. Under Energy<br />

Security, a 2-MW plant is planned for<br />

producing flexible CIGS-based solar cells.<br />

Initiatives have been taken to develop<br />

technologies to combat Low Intensity<br />

Conflict (LIC).<br />

DRDO is seeking to leverage the benefits<br />

of the offsets provision of Defence<br />

Procurement Procedures (DPP) 2010, with<br />

the aim of bringing in critical technologies<br />

into the country. The MoD is soon likely to<br />

amend the DPP to include collaborations<br />

with DRDO in R&D, joint development,<br />

and joint ventures as eligible offsets.<br />

CONTRIBUTIONS<br />

Over a million pieces of 7.62 mm Ishapore<br />

Self-Loading Rifle (SLR) developed by<br />

DRDO, were produced till these rifles<br />

were replaced by 5.56mm INSAS series,<br />

DRDO developed ecosystem<br />

DRDO has contributed a lot towards development of Indian Private Industry in the<br />

defence sector. With the launch of the LCA (Tejas) Programme, DRDO has developed<br />

an ecosystem with the support of users, academia, and private and public industries<br />

for design, development and manufacturing of aerospace and aviation products.<br />

According to Mr Ravi Kumar Gupta, Scientist G & Director, Directorate of Public<br />

Interface, DRDO Hqrs Public Interface, DRDO, all the partners have benefited<br />

immensely by this DRDO initiative.<br />

In the Tejas Light Combat Aircraft programme, HAL, Indian Air Force, IITs, IISc,<br />

various DRDO labs, private and public sector industries actively participated as<br />

development partners. Now India has developed its own design capability and also<br />

design and development facilities.<br />

another DRDO product forming main stay<br />

of our armed forces as well as paramilitary<br />

forces.<br />

In the field of electronic warfare,<br />

communication and radars, Artillery<br />

Combat Command Control System<br />

(ACCCS), Indian Doppler Radar INDRA-I<br />

& II, Rajendra - multifunction phased<br />

array radar, Super Vision Maritime Patrol<br />

Radar (SV-2000 MPAR), Avalanche Victim<br />

Detector (AVD), Battle Field Surveillance<br />

Radar-BFSR, a man-portable, battlefield<br />

and perimeter surveillance radars have<br />

been produced in large numbers.<br />

T-72 Ajeya tanks were upgraded with<br />

indigenous technologies and equipped<br />

with Explosive Reactive Armour (ERA),<br />

Global Positioning System (GPS),<br />

Integrated Fire Detection & Suppression<br />

System (IFDSS) & reconfigured Smoke<br />

Grenade Discharger (SGD). Over 700<br />

such Combat Improved Ajeya Tanks has<br />

been produced. BHIM self Propelled 155<br />

mm gun is another notable product,<br />

designed and developed by DRDO,<br />

besides a wide range of battle support<br />

system such as mobile bridges, Armoured<br />

dozers, Armoured ambulances, Armoured<br />

engineering vehicles, NBC recce vehicles,<br />

counter mining flails, smart anti tank<br />

mines etc.<br />

Safety and efficiency of soldier, the man<br />

behind machines under the most diverse<br />

battlefield conditions (extremes of cold<br />

and heat, mountains, deserts, tropical<br />

forests and so on) is a high priority and<br />

DRDO has developed many Life Support<br />

Systems for Armed forces. Some of these<br />

products are Combat Free Fall system<br />

capable to withstand the harsh conditions<br />

of free fall from 30,000 ft., NBC Canister,<br />

Water Poison Detection Kit, Portable<br />

Decontamination Apparatus, NBC Filters/<br />

Ventilation systems, Packaged ready<br />

to eat foods, High Altitude Pulmonary<br />

Oedema (HAPO) chamber, Heating Gloves<br />

& Socks for extreme cold conditions, Biodigestor<br />

for treatment of human waste<br />

in extreme cold conditions, NBC for high<br />

altitude medical products and Advanced<br />

H1N1 kit for detection of swine flu.<br />

A large number of Naval Systems,<br />

materials and technologies have been<br />

developed and inducted by Navy. Shipborne<br />

sonar HUMSA, Air borne dunking<br />

sonar MIHIR, Submarine-sonar USHUS,<br />

Torpedo Advanced Light TAL, Advanced<br />

Panoramic Sonar Hull mounted (APSOH),<br />

PACHENDRIYA - integrated submarine<br />

sonar and tactical fire control system,<br />

Auto-controlled Carbon Dioxide Control<br />

System, Poly-LIST Dockblock - a substitute<br />

for teak wood used for dry docking of<br />

ships, Heavy duty non-skid paint, AB class<br />

of steel for naval applications, Underwater<br />

Acoustic Communication System, Antitorpedo<br />

decoy system and Fuel cell<br />

based power generation systems are<br />

some examples.<br />

The most significant contribution of<br />

DRDO was the creation of a system<br />

conducive to development of cutting edge<br />

technologies by developing partnerships<br />

A e r o m a g 14<br />

A e r o m a g 15

with academic/research institutions and with<br />

industries; creating exhaustive infrastructure, both,<br />

within the organization and the partners entities;<br />

creating centers of excellence and establishing high<br />

quality manpower resource.<br />

DRDO today possesses a wide spectrum of Core<br />

Competencies which include Systems Design &<br />

Integration of Complex Sensors, Weapon Systems<br />

The DRDO capabilities have allowed the country to<br />

enter into pacts with foreign countries comprising<br />

joint design and development of weapon systems<br />

and shift from the previous buyer-seller relation.<br />

Also, the defence infrastructure within the country<br />

now allows the manufacturers to demand transfer<br />

of technology thereby allowing the Indian industry<br />

to imbibe latest technology and develop at a much<br />

faster pace.<br />

& Platforms, Complex High-end Software Packages,<br />

Functional Materials, Test and Evaluation, Technology<br />

Transfer and Absorption. In addition, expertise and<br />

infrastructure have been built up for basic/applied<br />

research in relevant areas, Quality Assurance &<br />

Safety, and Project & Technology Management.<br />

The DRDO and the three Services carried out<br />

detailed analysis to identify the products and critical<br />

technologies that are required to be established<br />

within the country. The technologies are categorized<br />

into Buy, Make and Buy & Make categories, and<br />

strategies evolved to establish them in the country<br />

are by one of the following routes, namely, ‘In house<br />

development in DRDO’, ‘Joint development through<br />

National S&T labs and academia’, ‘Joint development<br />

through International collaboration’, ‘Acquisition of<br />

Matured Technologies through offset obligations’.<br />

The most valuable resource of the organisation is its<br />

highly trained and motivated human power. DRDO<br />

offers to its staff adequate professional ambiance in<br />

terms of flexibility of operation, autonomy, financial<br />

and managerial responsibilities. Advanced training,<br />

career and self development needs of the scientists<br />

are also given due attention.<br />

After the examination of the P Rama Rao<br />

Committee report by the Government followed by<br />

the directive to implement, DRDO has appointed<br />

an “Implementation Committee” to work out finer<br />

details for implementing its recommendations. The<br />

implementation process is progressing under the<br />

guidance of an Advisory Committee.<br />

The committee has also recommended for private<br />

sector participation in DRDO. The participation of<br />

private sector is primarily in the productionisation<br />

of developed systems, through concurrent<br />

engineering.<br />

There had been significant milestones along the<br />

way.<br />

A successful flight test of Rustom1 UAV was<br />

conducted recently. It was the second successful<br />

flight of “Rustom 1” being developed by the<br />

Aeronautical Development Establishment (ADE), a<br />

DRDO lab engaged in pioneering R&D work in the<br />

field of aeronautics.<br />

The “Rustom 1” has an endurance of 14 hours and<br />

altitude ceiling of 8000 metres. Rustom 1 has been<br />

achieved by converting a manned aircraft in to a<br />

UAV (Unmanned Aerial Vehicle) by removing pilot<br />

seat and making required electrical, mechanical and<br />

aerodynamic modifications.<br />

DRDO has also successfully flight tested its latest<br />

surface to surface Missile `PRAHAAR’ from Launch<br />

Complex III, off Chandipur Coast, ITR, Balasore, Orissa.<br />

The Missile with a range of 150 kms, comparable to<br />

ATACMS Missile of United States of America, fills<br />

the vital gap between Multi Barrel Rockets and<br />

Medium Range Ballistic Missiles. The Missile capable<br />

of carrying different types of warheads operates as<br />

battle field support system to the Indian Army.<br />

Nishant, the Unmanned Aerial Vehicle (UAV), had<br />

successfully completed the series of confirmatory<br />

trials conducted by the Indian Army at Chandan<br />

Range Pokharan recently.<br />

ADE had also conducted successfully the flight test<br />

of Lakshya-2 the Pilotless Target Aircraft (PTA); was<br />

built to meet the anticipated users requirements<br />

for such a vehicle for testing out their guns and<br />

DRDO and Indian Air Force have signed<br />

an agreement for series production of<br />

computerised pilot selection system (CPSS).<br />

The embedded micro controller based CPSS<br />

having built-in security features captures<br />

accurate, reliable and high-speed data relating<br />

to the skills of the candidates appearing for<br />

selection as pilot.<br />

missiles.<br />

The state-of-the-art system is an outcome of<br />

collaborative efforts of DRDO and the IAF. It<br />

comprehensively evaluates the qualities required<br />

for a highly demanding job of a military pilot such<br />

as psychomotor skills, information processing skills<br />

(speed and accuracy), coordination, visualization,<br />

time-sharing, etc by subjecting the candidate to<br />

perform concurrent multiple tasks. The system has<br />

been designed with built-in diagnostic facilities for<br />

ease of maintenance.<br />

DRDO has flight tested fourth consecutive<br />

successful Interceptor Missile test against Incoming<br />

Ballistic Missile in Endo atmospheric regime at 15<br />

Km altitude and achieved direct Hit.<br />

LCA Tejas, the country’s first indigenously designed,<br />

developed and produced fighter jet has achieved<br />

the Initial Operational Clearance (IOC).<br />

A e r o m a g 16<br />

A e r o m a g 17

Golden era for India<br />

in defence technology<br />

private Industry. We are ready to guide them<br />

for improving the quality. We will support all<br />

our industry partners and we will take it as a<br />

responsibility of DRDO. We have instituted a<br />

tight quality management system from the<br />

production of prototype itself with industry<br />

help.<br />

arena: Dr. Prahlada<br />

Dr. Prahlada has just assumed charge as the Vice-Chancellor of the<br />

Defence Institute of Advanced Technology (DIAT), a deemed university<br />

which is an autonomous organisation fully funded by the Department<br />

of Defence Research and Development Organisation. Before taking over, he<br />

was Distinguist Scientist and chief Controller of Aero Programmes, DRDO and<br />

had worked in the organization for the last 40 years.<br />

Dr. Prahlada, born on 5th Feb 1947 in Bangalore, is a Mechanical Engineer<br />

Graduate from University College of Engineering, Bangalore University<br />

(1969). Subsequently he got his Masters Degree in Aeronautical Engineering<br />

Department from IISc., Bangalore, with specialisation in Rockets and missile<br />

Systems and Ph.D. in Mechanical Engineering from Jawaharlal Nehru<br />

Technological University, Hyderabad. Since 1971 he has served in various ISRO<br />

and DRDO Establishments covering VSSC Trivandrum, ADE Bangalore, DRDL<br />

Hyderabad and DRDO HQrs at Delhi.<br />

As project Director for the mobile surface to air area defence missile system,<br />

AKASH, he has provided the technological and managerial leadership for about 1000 scientists/engineers working at various developmental<br />

centers over 20 years in the country. Large orders worth more than Rs.25,000 crores have been placed by Indian Army and Air force for<br />

production and delivery of Akash Missile System and associated radars.<br />

In his position as Director of the biggest DRDO laboratory, DRDL, during 1997-2005, he has provided leadership to many missile projects,<br />

new technologies and world class test facilities. He was Programme Director for the Joint Venture Project (Indo-Russia) BrahMos and<br />

contributed to Project formulation, management and conduct of initial flight trials. He has spearheaded commercialisation of DRDO<br />

technologies into civilian products through a customised programme with FICCI.<br />

Excerpts from an exclusive <strong>Aeromag</strong> Asia interview with him:<br />

You have taken over as Vice-Chancellor<br />

of Defence Institute of Advanced<br />

Technology. What’s your vision here?<br />

My aim is to transform this Institute as a<br />

world class institution in advanced defence<br />

technologies on similar lines as Naval<br />

Postgraduate School in USA.<br />

What’s the update on DRDO’s<br />

international cooperation? Could you<br />

talk about some of the recent important<br />

MoUs and tie-ups, and are there any new<br />

agreements in the pipeline?<br />

We are working in close cooperation with<br />

a number of countries and companies in<br />

the international scene. We have product<br />

development and technology collaboration<br />

with Israel, France, Brazil and Singapore.<br />

We have Advance research cooperation<br />

with Kyrgystan, Belarus, Czech Republic,<br />

Government institutions and private<br />

Industry in Germany. We are closely<br />

working with Russia for the development<br />

of fifth generation fighter Aircraft and<br />

BrahMos Missile. With USA also, we have<br />

technology collaboration. DIAT also have<br />

collaboration with NPS. So we can jointly<br />

work with any country or institution<br />

for Research and Development and<br />

Technology development. In the UK, we<br />

have technical collaboration with Academia<br />

and government.<br />

Could you share your thoughts on<br />

recent developments in the area of<br />

commercialisation of DRDO technologies<br />

into civilian products, and the road-map<br />

you see for this kind of activity going<br />

forward?<br />

We had identified 20 technologies for<br />

commercialisation in the last 10 years. We<br />

adopted an open and transparent system<br />

for giving licence for the manufacturing of<br />

10 products so far in India.<br />

Even some outside countries have also<br />

showed interest in our technology. USA<br />

has showed interest in the production<br />

of explosives detection kit developed<br />

by DRDO. A Korean company has come<br />

forward for our short range radar. Ten more<br />

technologies are also in pipeline and all<br />

the 20 technologies will be transferred to<br />

commercial use within this year.<br />

We will continue to identify another 20<br />

projects from 2012.<br />

Could you elaborate on DRDO’s focus<br />

on futuristic technology development?<br />

Some of the major areas where we are<br />

working for advanced weapons include<br />

Short range and long range Missile in<br />

collaboration with Israel and France. Similarly<br />

we are working on Air to Air and Ground<br />

to Air Missile development and Precision<br />

guided munitions for future applications.<br />

In Aero Programme, we have world class<br />

projects. We are developing Advanced<br />

Indian AWACS, Rustom – long endurance,<br />

UAVs, Solar powered Unmanned Air<br />

vehicles, Fifth Generation modern combat<br />

aircraft development in collaboration with<br />

Russia, the LCA project and Electronic<br />

Warfare Systems to all Combat aircraft<br />

with Indian Air Force including LCA, MiG29,<br />

Sukhoi, Jaguar and Mirage.<br />

We are developing Aerostat of two<br />

different size and capabilities. As a long<br />

term project we will have an Airship<br />

programme. Even though some of<br />

our projects are delayed, the end users<br />

including Army, Air Force and Navy have<br />

accepted all DRDO developed products<br />

and placed orders. This has confirmed<br />

users commitment to indigenously<br />

developed products once they meet their<br />

expectations.<br />

What details can you share with us<br />

on ‘Defence Technology Vision 2050’<br />

roadmap being framed?<br />

For the next 20 years we will follow the<br />

LTIPP – Long Term Integrated Prospective<br />

Planning document of Defence Ministry<br />

for development of new products and<br />

technologies. New initiatives cover cyber<br />

security, low intensity conflicts and satellite<br />

based systems.<br />

We are working on combat aircraft,<br />

maritime Surveillance radar, Weapon<br />

locating Radars and Central Acquisition<br />

radars. Next technology communication<br />

and EW systems are on the anvil.<br />

Could you throw more light on the 1500<br />

horsepower engine and artillery guns of<br />

155 mm calibre that you are working on?<br />

Our own, we have taken a decision that<br />

with either foreign collaboration or with<br />

support from public and private sector, we<br />

will develop the tank engine of 1000hp and<br />

1500hp. We have also decided to make our<br />

own gas turbine engine for aircraft, marine<br />

gas turbine engine for Ship though these<br />

are highly complex technology challenges.<br />

Considering difficulties experienced by<br />

Indian Army in requiring artillery guns,<br />

DRDO has been requested by the army to<br />

taken up indigenous develop of 155 calibre<br />

guns.<br />

How is DRDO able to meet the high<br />

standards of quality and technology for<br />

its end-users?<br />

The quality of defence product during<br />

production comes from industry. The<br />

production part will be done by DPSUs, and<br />

What are the other new initiatives of<br />

DRDO?<br />

DRDO has already started supporting the<br />

innovations in a big way not only in science<br />

and technology but also administration and<br />

management.<br />

There should be synergy between Industry<br />

and academia. User, DRDO, Industry and<br />

Academia should work and should expand<br />

laterally for understanding each other.<br />

Horizontal integration, of these 4 entities<br />

while their deep specialization have to<br />

coexist.<br />

Unless it happens, we cannot have a<br />

synergy. For increasing the productivity<br />

and efficiency, DRDO should collaborate<br />

with academia for research and also user in<br />

operation. Industry should be a part from<br />

the development of prototype.<br />

There is no major defence programme<br />

going on in Europe or USA because of their<br />

current financial cries. Russian defence<br />

programme for the development of fifth<br />

generation fighter is also being done with<br />

India’s support.<br />

Thus, there is lot of potential in Europe and<br />

India should tap and utilise this opportunity.<br />

This is considered to be a golden era for<br />

India. Since there are no major defence<br />

programmes in developed countries will be<br />

ready to collaborate with India.<br />

We should exploit and utilise this golden<br />

opportunity to improve our capability<br />

and capacity in developing high tech<br />

engineering products.<br />

A e r o m a g 18<br />

A e r o m a g 19

MIDHANI<br />

may set up second plant to<br />

meet booming demand<br />

Mishra Dhatu Nigam Limited - MIDHANI has<br />

embarked on an ambitious expansion plan funded by<br />

the MOD as well as with support from Customers,<br />

says its Chairman and Managing Director Mr. M<br />

Narayana Rao in an exclusive interview to Managing<br />

Editor of <strong>Aeromag</strong> Asia, Sunny Jerome. The new<br />

facilities will enhance MIDHANI’s capabilities to<br />

meet the stringent quality requirements and pressing<br />

demands of customers in terms of quantities.<br />

modern metallurgical facilities and high<br />

degree of technical competence for<br />

manufacturing a wide range of super alloys,<br />

titanium, special purpose steels and other<br />

special metals and alloys meeting stringent<br />

quality requirements for application in<br />

Aerospace, defense, Atomic energy, Power<br />

generation, chemical and other high tech<br />

industries. MIDHANI is unique in the sense<br />

that it is one of very few industries in the<br />

world to have multitude of equipment<br />

housed under one roof and this facilitates<br />

the production of hundreds of different<br />

alloys in different forms. Equipment apart,<br />

MIDHANI has a highly qualified and skilled<br />

workforce which is well versed in the<br />

manufacturing process. Apart from the<br />

regular bars, flats, sheets / strips, wires,<br />

MIDHANI has also been supplying near net<br />

shape components to various customers.<br />

What about the client base?<br />

Space, Defense, Atomic energy, General<br />

engineering and power sectors form the<br />

broad client base of MIDHANI. Our main<br />

Customers are ISRO, BARC, DRDO, NPCIL,<br />

Ordnance Factories, Gun carriage factory,<br />

Navy , BHEL, L&T, WIL, Areva, to name a<br />

few.<br />

Any new investment, expansion plans<br />

going forward?<br />

MIDHANI has embarked on an ambitious<br />

expansion plan funded by the MOD as well<br />

as with support from Customers. Primary<br />

melting furnace -20T, Electron beam<br />

melting furnaces, 6000T forge press, Ring<br />

rolling mill, Wide plate mill and numerous<br />

state-of-the-art equipment, are under<br />

procurement. These new facilities will<br />

enhance MIDHANI’s capabilities to meet<br />

the stringent Quality requirements and<br />

pressing demands of Customers in terms<br />

of quantities. In the recent past, MIDHANI<br />

has already commissioned two re-melting<br />

furnaces of enhanced capacity.<br />

What are the company’s medium and<br />

long term goals?<br />

With the growing demand of the<br />

strategic sector, MIDHANI is already in<br />

the process of expanding capacity for<br />

increase of production. But with the space<br />

limitation of the present plant, it may<br />

become imperative to set up a second<br />

unit to meet the ever increasing demands<br />

of the space, power and defense sectors.<br />

Plans are afoot to formulate a long term<br />

strategy to achieve this goal.<br />

What is the hiring strategy of<br />

MIDHANI ?<br />

MIDHANI has been recruiting 20-25<br />

Management trainees directly from the<br />

premier institutions of the country every<br />

year for the past five years, by way of<br />

campus selections, in order to replenish<br />

the declining strength of officers due to<br />

superannuation. As and when required,<br />

personnel are being recruited in middle<br />

and senior management levels.<br />

Could you share the operational<br />

highlights of Midhani in 2010-11 and<br />

what is the growth you are tracking in<br />

the current fiscal?<br />

MIDHANI has recorded a sales turnover<br />

of Rs 417 Crores during the financial year<br />

2010-11 and a net profit of Rs 50.4 Crores.<br />

The total tonnage produced is 3014 MT.<br />

This amounts to a growth of 12 % over the<br />

previous year. Growth envisaged in current<br />

year is about 13%. MIDHANI is aiming for<br />

a sales turnover of about Rs 471 Crores<br />

during the year <strong>2011</strong>-12.<br />

What are the initiatives lined up in the<br />

near future?<br />

MIDHANI has an ambitious R&D<br />

program for developing new alloys<br />

for semi-cryogenic engine, special low<br />

alloy steels for armament and naval<br />

applications, titanium and special steels<br />

for missile program and special steels<br />

and superalloy for Ultra Super-Critical<br />

power plants. MIDHANI is also planning<br />

to contribute to the ambitious nuclear<br />

power program in a big way. In addition<br />

to alloy development, MIDHANI has<br />

also embarked on indigenization and<br />

modification of equipment which has<br />

resulted in fabrication of cutting machines,<br />

sophisticated melting furnaces etc.<br />

MIDHANI is also actively collaborating with<br />

research labs in developing new materials<br />

/ processes.<br />

Could you talk about the fastener<br />

plant that is coming up?<br />

Fasteners play a major role in machine<br />

building and the fasteners used in<br />

aerospace and other strategic sectors<br />

differ considerably from those used for<br />

general engineering purpose. The market<br />

potential for these fasteners is very high<br />

and many of our customers from the<br />

strategic sector have been sending us<br />

enquiries for various types of fasteners<br />

of different alloys. Presently, bulk of the<br />

requirements is being imported.<br />

The manufacture of these fasteners<br />

requires very stringent Quality control<br />

practices to be followed right from raw<br />

material stage to the finished component.<br />

MIDHANI has a quality system in place<br />

which adequately takes care of this<br />

requirement. In addition, MIDHANI has<br />

established manufacturing and processing<br />

routes for special steels, super alloys and<br />

titanium alloys required for manufacture<br />

of these fasteners. So it was natural for<br />

MIDHANI to get into this line of products.<br />

The fastener plant will be completely<br />

managed by women employees only. The<br />

growing demand for fasteners presents<br />

a novel opportunity where women’s<br />

skills and strengths can be captured<br />

in manufacturing these value added<br />

products.<br />

What do you propose to do as far as<br />

your MOU with SAIL is concerned?<br />

MIdhani is a high technology plant with<br />

know-how for many critical and strategic<br />

materials while SAIL is a giant in terms<br />

of capacities and capabilities. An MOU<br />

between two such companies can be<br />

beneficial in terms of production of critical<br />

alloys on a large scale, scaling down of<br />

processes during developmental stage and<br />

many more benefits, including availability<br />

of products at competitive costs, to both. A<br />

task force comprising members from both<br />

the stakeholders is already making an in<br />

depth study of the areas where profitable<br />

and meaningful contributions can be<br />

made. The MOU will go a long way in<br />

making available many strategic alloys for<br />

critical applications for the Indian industry<br />

indigenously.<br />

Could you briefly talk about the<br />

technological capability, facilities and<br />

products of MIDHANI?<br />

MIDHANI is an ISO 9001 company with<br />

Innovative Technologies, Integrated Security Solutions<br />

CTX 9800 DSi CTX 5800 HRX 1500 <br />

Itemiser ® DX<br />

StreetLab ® Mobile<br />

For more information on our products, please contact us at<br />

+91 98451 30160 or pravin.surana@morpho.com<br />

www.morpho.com/detection<br />

Hardened MobileTrace ® ShoeScanner XRD 3500 <br />

A e r o m a g 20<br />

A e r o m a g 21<br />

© <strong>2011</strong> Morpho Detection, Inc. All rights reserved. CTX 9800 DSi, CTX 5800, ShoeScanner, HRX 1500 and XRD 3500<br />

are trademarks, and Itemiser, StreetLab and MobileTrace are registered trademarks of Morpho Detection, Inc.

Will grow rapidly in India,<br />

says Honeywell<br />

Honeywell expects to grow rapidly in India, Mr. Pritam Bhavnani,<br />

President , Honeywell Aerospace India , told Sunny Jerome,<br />

Managing Editor of <strong>Aeromag</strong> Asia, in an exclusive interview.<br />

The company is setting up a research and development centre in<br />

Gurgaon to address its European business. Honeywell currently<br />

has around 12,000 employees in India. A significant amount of<br />

R&D and engineering works, as well as development of aero plane<br />

products are done in Bangalore. Fight control system, avionics and<br />

engine modifications are some of the key areas of development. It is<br />

not like back office work; real work is done in Bangalore. Excerpts<br />

from the interview.<br />

How important is the Indian market<br />

for Honeywell?<br />

It is very important from multiple<br />

points of view. One, obviously, is people’s<br />

talent, skill and capability. It is the very<br />

important part. If you look at the number<br />

of employees Honeywell has, India is the<br />

number two in terms of the headcount<br />

after the US.<br />

The second is obviously the market,<br />

the volume of business that we can have<br />

in India. Honeywell’s revenue in India<br />

is around USD 500 million of the total<br />

revenue of USD 33 billion – USD 34 billion.<br />

So, half of the billion is coming from India.<br />

Not that big now, but we are expecting to<br />

grow very rapidly in the future.<br />

And also we do a lot of exports out<br />

of India – turbochargers for example.<br />

In Pune, we made turbochargers for<br />

companies like Tata and Mahindra. And<br />

also we export them to Thailand, Europe,<br />

and other places. Two years ago, we made<br />

400,000 and 800,000 last year, and this we<br />

will go up to 1.5 million turbochargers in<br />

Pune. So the volume has doubled two<br />

years in a row and most of this being<br />

exported to Thailand and Europe also. It is<br />

all coming out of Pune.<br />

What are the new initiatives coming?<br />

I told you that, in case of turbochargers,<br />

we are growing tremendously. In design<br />

and development engineering, we are<br />

growing tremendously. We are also adding<br />

a new research and development centre<br />

in Gurgaon for our European business,<br />

which is the petrochemical business<br />

where we will be going, what Honeywell<br />

does in Europe.<br />

We actually design the process and the<br />

catalyst that are needed to convert raw of<br />

feed stocks whether it is crude oil and L.G<br />

oil to convert to diesel, kerosene, petrol,<br />

jet fuel etc. That conversion process is<br />

what Honeywell’s knowledge is and we<br />

are experts at that.<br />

So we have done one big centre in US<br />

and we will be setting up one in Gurgaon<br />

this year. Crude oil in Saudi Arabia is<br />

different from the crude oil in Bombay<br />

High and in the US and or in Russia. Each<br />

crude oil has different properties.<br />

What are the new trends you are<br />

seeing in Indian Defence market?<br />

I think Indian Defence market is going<br />

to through certain changes. One of the<br />

elements is modernising of the aircraft.<br />

If you look at the aircraft previously,<br />

the transport aircraft of Russian origin<br />

designed from 70s and 80s that we<br />

purchased. Now the new transport aircraft<br />

which has been purchased C-130, C-70<br />

and they will start taking over the main<br />

responsibility because they are more fuel<br />

efficient, take off and land in a shorter<br />

runway. They don’t need any finished<br />

runway or concrete runway. So there<br />

is the advantage to those aircraft, they<br />

will get more use and there are a lot of<br />

Honeywell components on them. We are<br />

working with the airports to establish the<br />

maintenance requirements, maintenance<br />

facility for Honeywell products.<br />

In Hyderabad, we have done another<br />

R&D centre actually. R&D is a service<br />

centre, one of the key things we provide<br />

from Hyderabad is also, what we call,<br />

Flight support Services. Flight Support<br />

services is for example for the business<br />

aircraft. For these aircraft when they<br />

are planning a flight, let’s say it is going<br />

to fly from Mumbai to Dubai-so we will<br />

from this Hyderabad centre, will get the<br />

information on this date, on this time we<br />

want to leave and this time we will arrive.<br />

So they will then plan out around it, give<br />

them all the view points, identify them,<br />

get all the weather picture, getting all<br />

the clearance while the aircraft is in the<br />

air, to follow them to make sure whether<br />

there is any problem or not.<br />

If there is any problem, they will send<br />

to alternate airport, to book even hotel<br />

to help them. By the time they land,<br />

hotel will already be there and cars<br />

also will be ready to pick them from the<br />

airport, because for these people time<br />

is so precious. One of the main things<br />

is supporting the flights of business<br />

aircraft and that support is done from<br />

Hyderabad for flights all over the world,<br />

not just in India but all over the world.<br />

Business aircraft in the US are also using<br />

Hyderabad centre for this for example.<br />

If you go on air with a good control<br />

from all these big TVs, tracking all flights<br />

in US and Europe, Asia, India and the<br />

different parts of the world, they have all<br />

control over all these people, each one is<br />

monitoring, helping, planning for future<br />

flights of getting clearances and working<br />

with the Airports for landing time and<br />

arrangements<br />

What are you doing on modernization<br />

of Indian Airports?<br />

I will give an idea about what we had<br />

done in Hyderabad and Delhi Airport on<br />

the new terminals. For example: Delhi<br />

Airport T3. All the security systems -- that<br />

means from video camera to the control<br />

room to the badge readers, whether<br />

someone has to put badge to open the<br />

door or close the door before you enter<br />

the airport -- all those badge readers, all<br />

those control system for the full security,<br />

the preliminary security of airport were<br />

done by Honeywell.<br />

All the air conditioning control system,<br />

all the lighting control systems, and the<br />

runway lights are done by Honeywell.<br />

So a lot of equipment into these large<br />

buildings and structures to manage<br />

electricity, energy, and all those things are<br />

done by Honeywell. So Hyderabad airport<br />

is the same thing, Delhi airport is the same<br />

thing, all the new airport coming up, we<br />

are working on Chennai with AAI and will<br />

work like this in future.<br />

What are the short term, medium<br />

term and long term plans?<br />

Short term, obviously continue what we<br />

are doing now, grow and expand. Medium<br />

term would be to do more research,<br />

more development but also not only for<br />

products made and operated in western<br />

world but also new products for India<br />

specifically. Now we are starting to look<br />

at what is needed in India that we can<br />

design in India and make it in India for the<br />

Indian Market. This is a kind of medium<br />

term. Then long term is also when to take<br />

development from both areas -- western<br />

development and Indian development<br />

-- and apply it different places. We call it<br />

“Upon East for East and East for West”.<br />

East for east means India for Indian market<br />

and east for west means the things we<br />

develop for western market.<br />

What’s the update on the human<br />

resources front?<br />

I think it depends upon the business<br />

growth. It is hard to put numbers on that.<br />

In 2002 or 2003, we had 1000 employees<br />

in India, but today we have 12,000<br />

employees in India. That means the<br />

growth rate is quiet good, so based on the<br />

business growth, something like this will<br />

continue. I think there is no resistance on<br />

the part of Honeywell to grow on.<br />

What are the takeaways from Paris<br />

Air show?<br />

Two big very clear announcements we<br />

made, one was on the green fuel. This<br />

fuel was used first to fly from the US to<br />

Europe. It was on Honeywell’s business<br />

jet and it was used to 50-50 random of<br />

normal oil based jet fuel verses the green<br />

fuel. We have the process to convert<br />

this into eco-friendly jet fuel. There are<br />

several advantages of the fuel that we<br />

developed.<br />

All aero planes which use this fuel will<br />

have less carbon emission so they have<br />

to pay less carbon tax. They can save<br />

money this way. And the other thing<br />

in regard to this fuel is that, it is being<br />

tested and certified by ASTM (American<br />

Society of Testing Material). Once it is<br />

certified, then all the refineries can start<br />

producing it, so the oil companies can<br />

start delivering it to airfield use by the<br />

airport.<br />

This fuel has been tested on about 10 or<br />

12 different types of aircraft in different<br />

engines in different parts of the world<br />

like the US, Korea, Japan, and Asia. It<br />

has been tested on Boeing aircraft, Air<br />

force Aircraft, GE engine, Helicopters,<br />

Fighter aircraft of the military. All types<br />

of engines, aircraft, and requirements<br />

are tested for the last 20 years. After all<br />

these thorough testing, it is certified<br />

and now it is ready for the actual use. It<br />

is important from efficiency perspective,<br />

environmental perspective.<br />