Raychem Heatshrink Products - RB Racing

Raychem Heatshrink Products - RB Racing

Raychem Heatshrink Products - RB Racing

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

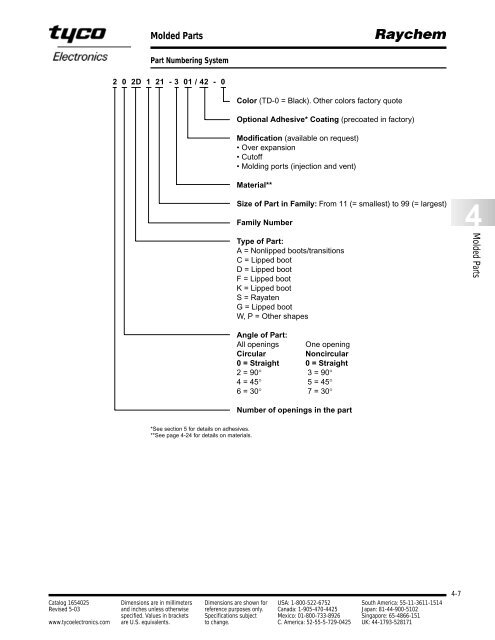

Molded Parts<br />

Part Numbering System<br />

2 0 2D 1 21 - 3 01 / 42 - 0<br />

Color (TD-0 = Black). Other colors factory quote<br />

Optional Adhesive* Coating (precoated in factory)<br />

Modification (available on request)<br />

• Over expansion<br />

• Cutoff<br />

• Molding ports (injection and vent)<br />

Material**<br />

Size of Part in Family: From 11 (= smallest) to 99 (= largest)<br />

Family Number<br />

Type of Part:<br />

A = Nonlipped boots/transitions<br />

C = Lipped boot<br />

D = Lipped boot<br />

F = Lipped boot<br />

K = Lipped boot<br />

S = Rayaten<br />

G = Lipped boot<br />

W, P = Other shapes<br />

4Molded Parts<br />

Angle of Part:<br />

All openings One opening<br />

Circular<br />

Noncircular<br />

0 = Straight 0 = Straight<br />

2 = 90° 3 = 90°<br />

4 = 45° 5 = 45°<br />

6 = 30° 7 = 30°<br />

Number of openings in the part<br />

*See section 5 for details on adhesives.<br />

**See page 4-24 for details on materials.<br />

Catalog 1654025 Dimensions are in millimeters Dimensions are shown for USA: 1-800-522-6752 South America: 55-11-3611-1514<br />

Revised 5-03 and inches unless otherwise reference purposes only. Canada: 1-905-470-4425 Japan: 81-44-900-5102<br />

specified. Values in brackets Specifications subject Mexico: 01-800-733-8926 Singapore: 65-4866-151<br />

www.tycoelectronics.com are U.S. equivalents. to change. C. America: 52-55-5-729-0425 UK: 44-1793-528171<br />

4-7

Materials<br />

Material Selection Table<br />

Applications<br />

Tyco Electronics offers <strong>Raychem</strong> products in a variety of materials to enable designers<br />

and material specifiers to obtain optimum performance.<br />

4-24<br />

Material*<br />

Characteristics<br />

A general purpose, heat-shrinkable semi rigid and flame retarded polyolefin molding compound with<br />

good resistance to fluids and heat. -3 molded parts are ideal for use in applications where toughness<br />

-3 Molded Part Material combined with resistance to occasional exposure to fluids or heat is required. -3 molded parts are<br />

recommended for use in System 10 and System 20.<br />

A general purpose, heat-shrinkable flame retarded, polyolefin compound used to make shielded<br />

molded parts.-3S molded parts form part of the Rayaten shielding system and are ideal for use in<br />

-3S Molded Part Material applications where toughness combined with resistance to occasional exposure to fluids or heat is<br />

required. -3S molded parts are recommended for use in System 10.<br />

A general purpose, heat-shrinkable flexible and flame retarded polyolefin molding compound with good<br />

resistance to fluids and heat. -4 molded parts are ideal for use in applications where toughness<br />

-4 Molded Part Material combined with resistance to occasional exposure to fluids or heat is required. -4 molded parts are<br />

recommended for use in System 10 and System 20.<br />

Designed for use in applications where extreme flexibility is required. The parts provide excellent strain<br />

-6 Molded Part Material relief and sealing over a broad temperature range and remain flexible at very low temperatures. The<br />

standard colour is black.<br />

For use in outer space, where use of low outgassing components is required. The parts provide<br />

-8 Molded Part Material excellent strain relief at connector cable terminations. Please contact <strong>Raychem</strong> for available shapes.<br />

The standard colour is black.<br />

A high temperature, heat-shrinkable, flexible, flame retarded, fluoroelastomeric molding compound with<br />

-12 Molded Part Material excellent resistance to long term fluid immersion and heat exposure. A wide range of shapes are<br />

available in this material. -12 molded parts are recommended for use in System 200.<br />

A heat-shrinkable, semi rigid, fluid and temperature resistant, elastomeric molding compound,<br />

designed to offer excellent performance in harsh environments. Ideal for use in military vehicles where<br />

-25 Molded Part Material high temperatures and long term exposure to hot fluids is expected. A wide range of shapes are<br />

available in this material. -25 molded parts are recommended for use in System 25.<br />

A heat-shrinkable, semi rigid, fluid and temperature resistant, elastomeric compound, used to make<br />

shielded molded parts. -25S molded parts form part of the Rayaten shielding system and are ideal for<br />

-25S Molded Part Material use in military vehicles where high temperatures and long term exposure to hot fluids is expected.<br />

-25S molded parts are recommended for use in System 25.<br />

A heat-shrinkable, highly flexible, fluid and temperature resistant, VPB molding compound, ideal for<br />

use in general purpose and high temperature military applications where exposure to petroleum based<br />

-50 Molded Part Material solvents is expected. Uniboots and a wide range of low profile shapes are available in this material.<br />

-50 molded parts are recommended for use in System 30 and are compatible with System 25<br />

components.<br />

A heat-shrinkable, rugged, flexible, fluid and temperature resistant, EPB molding compound, ideal for<br />

-51 Molded Part Material use in general purpose applications where exposure to petroleum based solvents is expected.<br />

Uniboots and a wide range of low profile shapes are available in this material. -51 molded parts are<br />

recommended for use in System 20.<br />

A heat-shrinkable, flexible, flame retarded, fluid and high temperature resistant, modified fluoropolymer<br />

-55 Molded Part Material molding compound. -55 molded parts are ideal for use in applications where resistance to the effects<br />

of N.B.C. agent exposure and decontamination, combined with excellent abrasion resistance is<br />

required. A wide range of shapes is available. -55 molded parts are recommended for use in<br />

System 300.<br />

A heat-shrinkable, flexible, fluid and temperature resistant, polyolefin molding compound, ideal for use<br />

-71 Molded Part Material in general purpose applications where a good balance of fluid and heat resistance properties is<br />

required. Uniboots and a wide range of low profile shapes are available. -71 molded parts are suitable<br />

for use in System 10.<br />

A heat-shrinkable, semi flexible, low fire hazard molding compound designed to offer excellent fire<br />

-100 Molded Part Material safety characteristics combined with low smoke and low acid gas emission -100 also exhibits good<br />

mechanical and fluid resistance properties. A wide range of shapes are available in this material. -100<br />

molded parts are recommended for use in System 100.<br />

A heat-shrinkable, semi flexible, low fire hazard compound used to make shielded molded parts. 100S<br />

-100S Molded Part Material molded parts form part of the Rayaten shielding system and are designed to offer excellent fire safety<br />

characteristics combined with low smoke and low acid gas emission. -100S also exhibits good mechanical<br />

and fluid resistance properties. -100S molded parts are recommended for use in System 100.<br />

A heat-shrinkable, flame retarded, fluid and high temperature resistant, modified fluoropolymer molding<br />

-125 Molded Part Material compound 125 molded parts are ideal for use in applications where resistance to the effects of N.B.C.<br />

agent exposure and decontamination, combined with excellent abrasion resistance is required. A<br />

range of shapes are available. -125 molded parts are recommended for use in System 300.<br />

-130 Molded Part Material Non flame-retarded molded material.<br />

-146 Molded Part Material Flame retarded, ultra-high ratio heat-shrinkable material.<br />

-152 Molded Part Material Flame retarded, high ratio heat-shrinkable material.<br />

*Check with specific part page for applicable materials.<br />

Catalog 1654025 Dimensions are in millimeters Dimensions are shown for USA: 1-800-522-6752 South America: 55-11-3611-1514<br />

Revised 5-03 and inches unless otherwise reference purposes only. Canada: 1-905-470-4425 Japan: 81-44-900-5102<br />

specified. Values in brackets Specifications subject Mexico: 01-800-733-8926 Singapore: 65-4866-151<br />

www.tycoelectronics.com are U.S. equivalents. to change. C. America: 52-55-5-729-0425 UK: 44-1793-528171

Adhesives<br />

Table of Contents<br />

Tyco Electronics manufacturers<br />

<strong>Raychem</strong> adhesives<br />

and sealants to accommodate<br />

a wide range of applications,<br />

materials, and<br />

environmental conditions.<br />

<strong>Raychem</strong> adhesives include<br />

both thermosets and thermoplastics.<br />

Thermosets are curable<br />

two-part epoxies or<br />

crosslinked elastomers.<br />

Thermoplastics are hot-melt<br />

adhesives that flow when<br />

heated and set when<br />

cooled. They reflow when<br />

reheated to simplify<br />

component repair.<br />

Tyco Electronics also manufactuers<br />

<strong>Raychem</strong> products<br />

that include a thermoplastic<br />

adhesive or a mastic-type<br />

sealant for water holdout<br />

applications. The sealants<br />

adhere to non-oily substrates<br />

and can be removed<br />

where reentry is necessary.<br />

Selection Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2<br />

Adhesive/Sealant Selection Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2<br />

Adhesive/Sealant product Characteristics Table . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3, 5-4<br />

Installation Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5 to 5-7<br />

5Adhesives<br />

Catalog 1654025 Dimensions are in millimeters Dimensions are shown for USA: 1-800-522-6752 South America: 55-11-3611-1514<br />

Revised 5-03 and inches unless otherwise reference purposes only. Canada: 1-905-470-4425 Japan: 81-44-900-5102<br />

specified. Values in brackets Specifications subject Mexico: 01-800-733-8926 Singapore: 65-4866-151<br />

www.tycoelectronics.com are U.S. equivalents. to change. C. America: 52-55-5-729-0425 UK: 44-1793-528171<br />

5-1

Adhesives<br />

Selection Guide<br />

To determine the adhesive<br />

or sealant most compatible<br />

with a <strong>Raychem</strong> part, you<br />

must know the part’s<br />

product type.<br />

Use the Adhesive/Sealant<br />

Selection Table below to<br />

determine a <strong>Raychem</strong> part’s<br />

product type and the<br />

adhesive/sealant compatible<br />

with that type.<br />

Use the Adhesive/Sealant<br />

Product Characteristics<br />

Table (pages 5-3 and 5-4)<br />

to be sure the adhesive or<br />

sealant has the product<br />

characteristics your application<br />

requires.<br />

To use the Selection Table,<br />

follow these four steps:<br />

1. Under “Substrate<br />

Category,” find the product<br />

material and product<br />

name/part number for the<br />

<strong>Raychem</strong> part.<br />

2. Across the top of the<br />

table, find the part’s<br />

product type and dash<br />

number.<br />

3. At the intersection of the<br />

substrate category (product<br />

material/name/part<br />

number) and the product<br />

type (by designated<br />

dash number) you will<br />

find the part number for<br />

the most compatible<br />

adhesive for the<br />

<strong>Raychem</strong> part.<br />

4. See the Adhesive/<br />

Sealant Product<br />

Characteristics Table<br />

below to verify the<br />

characteristics of the<br />

adhesive/sealant you<br />

selected.<br />

Adhesive/Sealant Selection Table<br />

Substrate<br />

Category<br />

Polyolefin<br />

Product<br />

Name<br />

Molded Part Material Dash Number<br />

Examples -3 -4 -6 -8 -12 -25 -50 -51 -55 -71 -100 -125 -130<br />

RNF-100 S-1006 S-1006 — — — — — — — S-1006 — — S-1006<br />

Versafit S-1009 S-1009 — — — — — — — S-1009 — — S-1009<br />

CRN S-1017 S-1017 — — — — — — — S-1017 — — S-1017<br />

BSTS S-1030 S-1030 — — — — — — — S-1030 — — —<br />

SST S-1048 S-1048 — — — — — — — S-1048 — — —<br />

HR S-1298 S-1297 — — — — — — — S-1297 — — —<br />

S-1009 S-1009 — S-1009 — S-1125 — — — S-1009 — S-1009 —<br />

Kynar S-1048 S-1048 — — — — — — — S-1048 — S-1048 —<br />

Fluoro- S-1125 S-1125 — — — — — — — S-1125 — S-1125 —<br />

polymer RT555 — — — — S-1255 — — — S-1255 — — S-1255 —<br />

HCTE — — — — S-1255 S-1125 — — S-1255 — — — —<br />

CONVOLEX — — — — S-1125 — — — S-1125 — — — —<br />

S-1006 S-1006 — — — — — — — S-1006 — — —<br />

Vinyl PVC S-1009 S-1009 — — — — — — — S-1009 — — —<br />

S-1017 S-1017 — — — — — — — S-1017 — — —<br />

DR-25 — — — — — S-1125 S-1125 S-1125 — — — — —<br />

S-1006 S-1006 — — — — — S-1124 — S-1006 — — —<br />

NT S-1009 S-1009 — — — — — — — S-1009 — — —<br />

S-1017 S-1017 — — — — — — — S-1017 — — —<br />

Elastomer<br />

NT-FR — — — — — S-1125 — S-1124 — — — — —<br />

SFR — — * — — — — — — — — — —<br />

SRFR — — * — — — — — — — — — —<br />

VITON — — — — S-1255 — — — S-1255 — — S-1255 —<br />

VPB<br />

— — — — — — S-1125 — — — — — —<br />

— — — — — — S-1255 — — — — — —<br />

Zerohal<br />

XFFR — — — — — — — — — — S-1030 — —<br />

ZHTM — — — — — — — — — — S-1030 — —<br />

*GE RTV 108 used with SFR SRFR and -6 (silicone) molded parts.<br />

5-2<br />

Catalog 1654025 Dimensions are in millimeters Dimensions are shown for USA: 1-800-522-6752 South America: 55-11-3611-1514<br />

Revised 5-03 and inches unless otherwise reference purposes only. Canada: 1-905-470-4425 Japan: 81-44-900-5102<br />

specified. Values in brackets Specifications subject Mexico: 01-800-733-8926 Singapore: 65-4866-151<br />

www.tycoelectronics.com are U.S. equivalents. to change. C. America: 52-55-5-729-0425 UK: 44-1793-528171

Adhesives<br />

Adhesive/Sealant Product Characteristics Tables<br />

Product<br />

Precoat<br />

Operating<br />

Product<br />

Available Form/<br />

Type<br />

Designation<br />

Type<br />

Temperature<br />

Range<br />

Designation<br />

Packaging<br />

Thermosets<br />

S-1006 —<br />

Epoxy/<br />

S-1006 Kit 1 Two x 15-gram packs<br />

-55°C to 135°C<br />

polyamide<br />

S-1006 Kit 2 Four x 7.5-gram packs<br />

two-part paste<br />

[-67°F to 275°F]<br />

S-1006 Kit A Ten 3-gram packs<br />

S-1009 —<br />

Epoxy/<br />

-55°C to 135°C<br />

polymercaptan<br />

two-part paste<br />

[-67°F to 275°F]<br />

S-1009 Kit A Ten 3-gram packs<br />

S-1255-04<br />

One-part epoxy -55°C to 200°C<br />

— tape adhesive [-67°F to 392°F]<br />

S-1255-04 Tape [3/4 in. x .020 x 100 ft.]<br />

S-1125 Kit 1 Five 10-gram packs<br />

S-1125 Kit 2 Two 10-gram packs<br />

S-1125 —<br />

Epoxy/polyamide<br />

-55°C to 150°C S-1125 Kit 3 One 100-gram pack<br />

two-part paste<br />

[-67°F to 302°F] S-1125 Kit 4 Five 10-gram packs<br />

S-1125 Kit 5 One 10-gram pack<br />

S-1125 Kit 8 Two 50-ml syringes<br />

/225<br />

Precoated<br />

-75°C to 150°C<br />

Precoat only on<br />

latent-curing<br />

[-103°F to 302°F]<br />

-25 molded<br />

epoxy/polyamide<br />

parts<br />

—<br />

Thermoplastics<br />

S-1017 /42<br />

Hot-melt/<br />

-20°C to 60°C***<br />

polyamide<br />

[-4°F to 140°F]<br />

S-1017 Tape [1 in. x .010 in. x 50 ft.]<br />

S-1030 /180<br />

Hot-melt/ -80°C to 80°C<br />

polyolefin<br />

[-112°F to 176°F]<br />

S-1030 Tape [3/4 in. x .010 in. x 33 ft.]<br />

S-1048 /86<br />

Hot-melt, -55°C to 120°C<br />

high performance [-67°F to 248°F]<br />

S-1048 Tape [1 in. x .026 in. x 100 ft.]<br />

S-1124 /164<br />

Hot-melt/<br />

elastomeric<br />

-55°C to 105°C<br />

polymer<br />

[-67°F to 221°F]<br />

S-1124 Tape [3/4 in. x .018 in.x 10 ft.]<br />

S-1297 /97<br />

Hot-melt/<br />

polyamide<br />

-20°C to 90°C]<br />

adhesive<br />

[-4°F to 194°F]<br />

S-1297 Tape [1 in. x .010 in. x 10 ft.]<br />

Sealants<br />

S-1278 — Hot-melt grey -40°C to 90°C S-1278-01 Tape [1 in. x .062 in. x 25 ft.]<br />

butyl sealant [-40°F to 194°F] S-1278-02 Tape [33/4 in. x .125 in. x 10 ft.)<br />

S-1305 —<br />

Hot-melt grey -40°C to 90°C<br />

butyl sealant<br />

[-40°F to 194°F]<br />

S-1305-01 Tape [1 in. x.062 in. x25 ft.]<br />

*Shelf life from date of manufacture.<br />

**For specific adhesion properties, see product specification sheets.<br />

***Passes cold bend at -40°C [-40°F] per RT-4204.<br />

****Only S-1006 Kit A conforms to MIL-A-46864.<br />

5Adhesives<br />

Catalog 1654025 Dimensions are in millimeters Dimensions are shown for USA: 1-800-522-6752 South America: 55-11-3611-1514<br />

Revised 5-03 and inches unless otherwise reference purposes only. Canada: 1-905-470-4425 Japan: 81-44-900-5102<br />

specified. Values in brackets Specifications subject Mexico: 01-800-733-8926 Singapore: 65-4866-151<br />

www.tycoelectronics.com are U.S. equivalents. to change. C. America: 52-55-5-729-0425 UK: 44-1793-528171<br />

5-3

Adhesives<br />

Adhesive/Sealant Product Characteristics Tables (Continued)<br />

Pot Life<br />

at 23°C<br />

Curing<br />

Conditions<br />

Shelf life* at<br />

or below<br />

25°C<br />

Specifications**<br />

Comments<br />

RT-1006<br />

General purpose harnessing adhesive.<br />

1 h 96 h at 20°C [68°F] min. or 2 years RK-6612 Not used on Viton, silicone or Kynar;<br />

1 hr at 120°C [248°F] 20-minute pot life<br />

MIL-A-46864****<br />

24 h at 20°C [68°F] min. or General purpose harnessing adhesive<br />

1 hr at 95°C [203°F] 2 years RT-1009 Not used on Viton or silicone;<br />

20 min 20-minute pot life<br />

45 min at 120°C [248°F] One-part epoxy tape used with Viton<br />

2 h at 155°C [311°F] min. or 1 year RT-1014 harness systems. Heat cure required<br />

15 min at 240°C [464°F] (2 hours at 155°C [311°F])<br />

RT-1011<br />

24 h at 20°C min. or<br />

18 months RK-6619<br />

Good fluid-resistant epoxy used with<br />

90 min 1 hr at 85°C [185°F]<br />

VG-95343<br />

System 25<br />

Cure during installation<br />

of molded parts<br />

1 year<br />

VG-95343<br />

RK-6630<br />

Precoated epoxy system for System 25<br />

General purpose harnessing adhesive<br />

— 120°C [248°F] Unlimited RT-1050/1 Standard precoated adhesive for -3<br />

and -4 molded parts<br />

— 120°C [248°F] Unlimited<br />

— 160°C [320°F] Unlimited<br />

RT-1050/6<br />

RK-6017<br />

RT-1050/3<br />

RK-6626<br />

Good low-temperature flexibility<br />

Available as a preinstalled tape for<br />

molded parts<br />

Requires high temperature to achieve<br />

bonding. Highest service temperature<br />

for hot melt<br />

Requires reflowing in an oven at 150°C [302°F]<br />

— 135°C [275°F] Unlimited RT-1050/13 for 90 minutes. Designed to bond to<br />

-51 molded parts.<br />

General purpose harnessing adhesive<br />

Standard precoated adhesive in<br />

— 120°C [248°F] Unlimited RW-2019 Sigmaform molded parts, CES and<br />

CSGA cable entry seals, and SST-FR<br />

heat-shrinkable tubing<br />

— 110°C [230°F] Unlimited RW-2020<br />

— 110°C [230°F] Unlimited RW-2021<br />

*Shelf life from date of manufacture.<br />

**For specific adhesion properties, see product specification sheets.<br />

***Passes cold bend at -40°C [-40°F] per RT-4204.<br />

****Only S-1006 Kit A conforms to MIL-A-46864.<br />

General purpose sealant and cable<br />

breakout area filler<br />

Halogen-free, flame-retardant sealant<br />

and cable breakout area filler<br />

5-4<br />

Catalog 1654025 Dimensions are in millimeters Dimensions are shown for USA: 1-800-522-6752 South America: 55-11-3611-1514<br />

Revised 5-03 and inches unless otherwise reference purposes only. Canada: 1-905-470-4425 Japan: 81-44-900-5102<br />

specified. Values in brackets Specifications subject Mexico: 01-800-733-8926 Singapore: 65-4866-151<br />

www.tycoelectronics.com are U.S. equivalents. to change. C. America: 52-55-5-729-0425 UK: 44-1793-528171

Adhesives<br />

Installation Guide<br />

Substrate Preparation<br />

Procedures<br />

Preparation of the substrate<br />

depends on the part to be<br />

bonded. Following are two<br />

preparation procedures.<br />

The first applies to plated<br />

metals and adapters; the<br />

second applies to polymer<br />

molded parts, cable jackets,<br />

and tubing materials.<br />

Plated Metals and Adapters<br />

Thoroughly degrease the<br />

surface with a clean cloth or<br />

paper wipe dampened with<br />

a solvent. The cloth or<br />

paper should not be saturated<br />

with the solvent.<br />

Allow the part to stand for<br />

a minute or two to allow<br />

complete evaporation of the<br />

solvent.<br />

Molded Parts, Cable Jackets,<br />

and Tubing Materials<br />

Carefully and evenly abrade<br />

the surface with #320 emery<br />

cloth. Wipe contaminants<br />

and abraded particles away<br />

with a clean cloth or paper<br />

wipe dampened with a solvent.<br />

The cloth or paper<br />

should not be saturated<br />

with the solvent. Allow the<br />

part to stand for a minute or<br />

two to allow complete evaporation<br />

of the solvent.<br />

Note:<br />

■ Avoid contamination of the prepared<br />

surface. If using primer,<br />

apply it according to the manufacturer’s<br />

instructions and allow it to<br />

dry.<br />

■ Epoxy adhesives may cause skin<br />

and eye irritation. Be sure to<br />

observe the handling instructions.<br />

■ When using hot-melt adhesives on<br />

substrates with high heat-sink<br />

capacity (such as connector backshells),<br />

preheat the substrate until<br />

it is hot to touch, then apply the<br />

adhesive tape and shrink the<br />

molded part in place.<br />

Caution:<br />

The use of cleaning solvent<br />

is described in the preparation<br />

of various components<br />

for adhesive bonding.<br />

Please observe the solvent<br />

manufacturer’s safety recommendations.<br />

Several<br />

<strong>Raychem</strong> epoxy adhesives<br />

and solvent base primers<br />

are also described in some<br />

cases. For specific handling<br />

precautions, please consult<br />

the appropriate <strong>Raychem</strong><br />

material safety data sheet<br />

for the adhesive being used.<br />

Installation Procedures<br />

The three sets of installation<br />

instructions that follow are<br />

based on the type and/or<br />

form of adhesive or sealant<br />

to be used.<br />

Select the set of instructions<br />

that applies to your<br />

application.<br />

Tape Adhesives and Sealants<br />

Connector Boot<br />

1. Degrease the area of the<br />

adapter to which the<br />

boot will be bonded,<br />

using appropriate solvent<br />

on a paper tissue or<br />

clean cloth. Do not<br />

abrade the adapter.<br />

2. Lightly abrade the bonding<br />

area of the cable<br />

jacket with #320 emery<br />

cloth, then wipe off loose<br />

particles with a tissue or<br />

clean cloth dampened<br />

with a solvent.<br />

3. Lightly abrade and wipe<br />

25.4 [1.0] back inside<br />

each end of the boot.<br />

4. When using primer,<br />

apply a thin, uniform<br />

coating to the bonding<br />

surface and let it air dry<br />

(15–20 minutes).<br />

5. Double-wrap the adhesive<br />

tape around the<br />

cleaned area of the<br />

adapter, placing slight<br />

tension on the tape as<br />

you wrap. Tack the ends<br />

in place with a soldering<br />

iron or hot tool.<br />

6. Double-wrap adhesive<br />

tape around the cable<br />

jacket where the end of<br />

the boot is to be located.<br />

7. Position the boot on the<br />

adapter and the cable.<br />

Apply heat, starting at<br />

the connector end.<br />

8. Recover the connector<br />

end of the boot onto the<br />

adapter and continue<br />

heating until the area is<br />

fully recovered and the<br />

adhesive tape is properly<br />

melted.<br />

9. Complete the recovery<br />

of the boot, continuing<br />

toward the cable end.<br />

Heat the cable end of<br />

the boot where the<br />

adhesive is placed, until<br />

the part is fully recovered<br />

and the tape has<br />

properly melted or<br />

flowed. The tape should<br />

appear wet, form a bead<br />

or fillet between the<br />

cable and boot, and<br />

show no definition<br />

between the layers of<br />

tape.<br />

10.Where oven curing is<br />

required to complete<br />

adhesive bonding, heat<br />

the assembled harness<br />

in a preheated oven<br />

according to the following<br />

schedule:<br />

S-1255-02:<br />

2 hours at 155°C [311°F]<br />

S-1124:<br />

90 minutes at 150°C [302°F]<br />

Transition<br />

1. Lightly abrade the bonding<br />

area of the cable<br />

jacket with #320 emery<br />

cloth, then wipe off loose<br />

particles with a tissue or<br />

clean cloth dampened<br />

with a solvent.<br />

2. Abrade and wipe the<br />

inside of each transition<br />

opening.<br />

3. When using primer,<br />

apply a thin, uniform<br />

coating to the bonding<br />

surface and let it air dry<br />

(15–20 minutes).<br />

5Adhesives<br />

Catalog 1654025 Dimensions are in millimeters Dimensions are shown for USA: 1-800-522-6752 South America: 55-11-3611-1514<br />

Revised 5-03 and inches unless otherwise reference purposes only. Canada: 1-905-470-4425 Japan: 81-44-900-5102<br />

specified. Values in brackets Specifications subject Mexico: 01-800-733-8926 Singapore: 65-4866-151<br />

www.tycoelectronics.com are U.S. equivalents. to change. C. America: 52-55-5-729-0425 UK: 44-1793-528171<br />

5-5

Adhesives<br />

Installation Guide (Continued)<br />

4. Double-wrap the tape<br />

around the abraded<br />

areas of the cable, placing<br />

slight tension on the<br />

tape as you wrap. Tack<br />

the ends in place with a<br />

soldering iron or hot tool.<br />

5. Center the molded part<br />

over the transition area.<br />

When properly positioned,<br />

the part should<br />

not fit tightly in the<br />

“branched” area of the<br />

breakout. A tight fit may<br />

cause the part to crease<br />

or wrinkle as it recovers.<br />

The tape should extend<br />

slightly beyond the end<br />

of the transition.<br />

6. Apply heat to the center<br />

of the transition. Recover<br />

one leg of the transition,<br />

moving heat from the<br />

center of the transition<br />

to the adhesive opening<br />

of the leg. Repeat the<br />

procedure on each leg<br />

of the transition.<br />

7. Continue heating each<br />

end of the transition until<br />

the part is fully recovered<br />

and the adhesive<br />

tape has properly<br />

melted or flowed. The<br />

tape should now appear<br />

wet, form a bead or fillet<br />

between the cable and<br />

transition, and show no<br />

definition between the<br />

layers of tape.<br />

8. Where oven curing is<br />

required to complete<br />

adhesive bonding, heat<br />

the assembled harness<br />

in a preheated oven<br />

according to the following<br />

schedule:<br />

S-1255-02:<br />

2 hours at 155°C [311°F]<br />

S-1124:<br />

90 minutes at 150°C [302°F]<br />

Thermosets<br />

Connector Boot<br />

1. Thoroughly mix the two<br />

parts according to the<br />

instructions provided<br />

with the kit.<br />

2. Degrease the area of the<br />

adapter to which the<br />

boot will be bonded,<br />

using appropriate solvent<br />

on a paper tissue or<br />

clean cloth. Do not<br />

abrade the adapter.<br />

3. Lightly abrade the bonding<br />

area of the cable<br />

jacket with #320 emery<br />

cloth, then wipe off loose<br />

particles with a tissue or<br />

clean cloth.<br />

4. Lightly abrade back 25.4<br />

mm [1.0] inside each<br />

end of the boot.<br />

5. Using a spatula, apply<br />

the mixed adhesive to<br />

the adapter and shrink<br />

the adapter to the end of<br />

the boot.<br />

6. Apply adhesive to the<br />

cable jacket and complete<br />

the shrinking<br />

process.<br />

7. With a clean cloth,<br />

remove excess adhesive<br />

from all areas<br />

immediately.<br />

8. Follow the curing conditions<br />

outlined in this<br />

guide.<br />

Transition<br />

1. Thoroughly mix the two<br />

parts according to the<br />

instructions provided<br />

with the kit.<br />

2. Lightly abrade the bonding<br />

area of the cable<br />

jacket with #320 emery<br />

cloth, then wipe off loose<br />

particles with a tissue or<br />

clean cloth.<br />

3. Abrade and wipe inside<br />

each opening of the<br />

transition.<br />

4. Using a spatula, apply<br />

the mixed adhesive to<br />

the cable jacket.<br />

5. Apply heat to the center<br />

of the transition. Recover<br />

one leg of the transition,<br />

moving heat from the<br />

center of the transition to<br />

the adhesive opening of<br />

the leg. Repeat the procedure<br />

on each leg.<br />

6. Remove excess<br />

adhesive from all areas<br />

immediately with a<br />

clean cloth.<br />

7. Follow the curing<br />

conditions specified for<br />

“thermosets” in the<br />

“Adhesive/Sealant<br />

Product Characteristics<br />

Table” on pages 5-3 and<br />

5-4.<br />

5-6<br />

Catalog 1654025 Dimensions are in millimeters Dimensions are shown for USA: 1-800-522-6752 South America: 55-11-3611-1514<br />

Revised 5-03 and inches unless otherwise reference purposes only. Canada: 1-905-470-4425 Japan: 81-44-900-5102<br />

specified. Values in brackets Specifications subject Mexico: 01-800-733-8926 Singapore: 65-4866-151<br />

www.tycoelectronics.com are U.S. equivalents. to change. C. America: 52-55-5-729-0425 UK: 44-1793-528171

Adhesives<br />

Installation Guide (Continued)<br />

Molded Parts Pre-coated<br />

with Thermoplastic<br />

Adhesive<br />

Connector Boot<br />

1. Degrease the area of<br />

the adapter to which<br />

the boot will be bonded,<br />

using appropriate solvent<br />

on a paper tissue<br />

or clean cloth. Do not<br />

abrade the adapter or<br />

inside surface of the<br />

boot.<br />

2. Lightly abrade the bonding<br />

area of the cable<br />

jacket with #320 emery<br />

cloth, then wipe off loose<br />

particles with a tissue or<br />

clean cloth dampened<br />

with solvent.<br />

3. Position the boot on the<br />

adapter and cable.<br />

Apply heat starting at<br />

the connector end.<br />

4. Recover the connector<br />

end of the boot onto the<br />

adapter and continue<br />

heating until the area is<br />

fully recovered and the<br />

adhesive is properly<br />

melted.<br />

5. Complete the recovery<br />

of the boot, continuing<br />

toward the cable end of<br />

the boot until the part is<br />

fully recovered and the<br />

adhesive is properly<br />

melted. The adhesive<br />

should form a bead or<br />

fillet between the cable<br />

and boot when fully<br />

melted.<br />

6. With a clean cloth,<br />

remove excess<br />

adhesive from all<br />

areas immediately.<br />

7. Follow the curing<br />

conditions outlined in<br />

this guide.<br />

Transition<br />

1. Lightly abrade the bonding<br />

area of the cable<br />

jacket with #320 emery<br />

cloth, then wipe off loose<br />

particles with a tissue or<br />

clean cloth dampened<br />

with solvent.<br />

2. Center the molded part<br />

over the transition area.<br />

3. Apply heat to the center<br />

of the transition. Recover<br />

one leg of the transition,<br />

moving heat from the<br />

center of the transition<br />

to the adhesive opening<br />

of the leg. Repeat the<br />

procedure on each leg<br />

of the transition.<br />

4. Continue heating each<br />

end until the part is<br />

fully recovered and the<br />

adhesive has properly<br />

melted. The adhesive<br />

should form a bead or<br />

fillet between the cable<br />

and transition when<br />

fully melted.<br />

5. Follow the curing<br />

conditions specified<br />

for “thermosets” in the<br />

“Adhesive/Sealant<br />

Product Characteristics<br />

Table” on pages 5-3 and<br />

5-4.<br />

5Adhesives<br />

Catalog 1654025 Dimensions are in millimeters Dimensions are shown for USA: 1-800-522-6752 South America: 55-11-3611-1514<br />

Revised 5-03 and inches unless otherwise reference purposes only. Canada: 1-905-470-4425 Japan: 81-44-900-5102<br />

specified. Values in brackets Specifications subject Mexico: 01-800-733-8926 Singapore: 65-4866-151<br />

www.tycoelectronics.com are U.S. equivalents. to change. C. America: 52-55-5-729-0425 UK: 44-1793-528171<br />

5-7

Adhesives<br />

Engineering Notes<br />

5-8 Catalog 1654025 Dimensions are in millimeters Dimensions are shown for USA: 1-800-522-6752 South America: 55-11-3611-1514<br />

Revised 5-03 and inches unless otherwise reference purposes only. Canada: 1-905-470-4425 Japan: 81-44-900-5102<br />

specified. Values in brackets Specifications subject Mexico: 01-800-733-8926 Singapore: 65-4866-151<br />

www.tycoelectronics.com are U.S. equivalents. to change. C. America: 52-55-5-729-0425 UK: 44-1793-528171

Heat-Shrink Tubing, Molded Parts and Adhesives<br />

Table of Contents<br />

METRIC<br />

Dimensions in this section<br />

are millimeters over inches<br />

Single-Wall Tubing<br />

CRN Semi-rigid, flame-retardant, polyolefin tubing . . . . . . . . .10004, 10005<br />

DCPT Flexible, flame-retardant, dual-color, polyolefin tubing . .10006, 10007<br />

DR-25<br />

Heat-shrinkable, flexible, chemical and abrasion<br />

resistant tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10008, 10009<br />

MicroFit Small-diameter, high-shrink-ratio tubing . . . . . . . . . . . . .10010, 10011<br />

NT/NTFR Very flexible, rugged neoprene elastomer tubing . . . . . .10012, 10013<br />

NT-MIL<br />

Flexible, Rugged, Modified Elastomeric heat-shrinkable<br />

tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10014, 10015<br />

RNF-100 Flexible, flame-retardant, general purpose,<br />

polyolefin tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10016, 10017<br />

RNF-150 High-performance, flame-resistant, flexible,<br />

fluoropolymer tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . .10018, 10019<br />

RNF-3000 Flexible, high-shrink-ratio, flame-retardant,<br />

general purpose, polyolefin tubing . . . . . . . . . . . . . . . . .10020, 10021<br />

RP-4800 High-shrink-ratio, flame-retardant, polyolefin tubing . . . .10022, 10023<br />

RT-3 Semi-rigid, flame-retardant, polyolefin tubing . . . . . . . . .10024, 10025<br />

RT-375 Clear, flame-resistant, flexible, fluoropolymer tubing . . .10026, 10027<br />

RT555<br />

Fluid-resistant, chemical resistant, crosslinked<br />

fluoropolymer tubing with extended temperature range . . .10028, 10029<br />

RW-175<br />

High temperature and fluid resistant, extra tough,<br />

semi-rigid, heat-shrinkable tubing . . . . . . . . . . . . . . . . . .10030, 10031<br />

SFR Very flexible, flame-retardant, silicone elastomer tubing . . .10032, 10033<br />

SRFR Silicone rubber, highly flexible, heat-shrinkable tubing . . .10034, 10035<br />

Versafit<br />

Highly, flame-retardant, very flexible,<br />

low-shrink-temperature, polyolefin tubing . . . . . . . . . . . .10036, 10037<br />

Versafit V4 Very-thin-wall, very flexible, highly flame-retardant,<br />

polyolefin tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10038, 10039<br />

Viton/Viton-HW/ Heat-shrinkable, chemical-resistant,<br />

Viton-E/Viton-TW high-temperature tubing . . . . . . . . . . . . . . . . . . . . . . . . .10040, 10041<br />

ZH-100 Flexible, thin-wall, low-fire-hazard tubing . . . . . . . . . . . .10042, 10043<br />

ZHTM<br />

Heat-shrinkable, flexible tubing with low toxicity for fire<br />

safety applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10044, 10045<br />

Adhesive Lined Tubing<br />

ATUM High-shrink-ratio, adhesive-lined polyolefin tubing . . . . .10046, 10047<br />

DWP-125 Flexible, high-shrink-ratio, adhesive-lined,<br />

polyolefin tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10048, 10049<br />

ES1000<br />

Clear, high-shrink-ratio, adhesive-lined, semi-rigid<br />

polyolefin tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10050, 10051<br />

ES2000<br />

Flame-retardant, high-shrink-ratio, adhesive-lined,<br />

semi-rigid polyolefin tubing . . . . . . . . . . . . . . . . . . . . . . .10052, 10053<br />

ES Caps<br />

High-shrink-ratio, adhesive-lined, semi-rigid<br />

polyolefin caps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10054, 10055<br />

HCTE Helical convolex tubing with a high crush resistance . . .10056, 10057<br />

PD Caps Semi-rigid, encapsulant-lined, polyolefin caps . . . . . . . .10058, 10059<br />

RayBlock 85 Heat-shrinkable water-blocking system . . . . . . . . . . . .10060, 10061<br />

RayBlock 105 Heat-shrinkable water-blocking system . . . . . . . . . . . .10062, 10063<br />

SCL Semi-rigid, encapsulant-lined, polyolefin tubing . . . . . . .10064, 10065<br />

10<br />

Heat-Shrink Tubing,<br />

Molded Parts and Adhesives<br />

Catalog 1308940 Dimensions are in millimeters Dimensions are shown for USA: 1-800-522-6752 South America: 55-11-3611-1514<br />

Revised 5-03 and inches unless otherwise reference purposes only. Canada: 1-905-470-4425 Japan: 81-44-900-5102<br />

specified. Values in brackets Specifications subject Mexico: 01-800-733-8926 Singapore: 65-4866-151<br />

www.tycoelectronics.com are U.S. equivalents. to change. C. America: 52-55-5-729-0425 UK: 44-1793-528171<br />

10001

Heat-Shrink Tubing, Molded Parts and Adhesives<br />

10002<br />

Table of Contents (Continued)<br />

SCT<br />

Flame-retardant, adhesive-lined, semi-rigid polyolefin,<br />

heat-shrinkable tubing (extended temperature range) . .10066, 10067<br />

TAT-125 Adhesive-lined, flexible polyolefin tubing . . . . . . . . . . . .10068, 10069<br />

Heavy-Walled Tubing<br />

BSTS/BSTS-FR General purpose, heat-shrinkable tubing . . . . . . . . . . . .10070, 10071<br />

HF High-flex, heavy-wall, heat-shrinkable tubing . . . . . . . . .10072, 10073<br />

HRHF/HRNF/ High-ratio, heat-shrinkable<br />

HRSR tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10074, 10075<br />

SST/SST-FR Self-sealing, heat-shrinkable tubing . . . . . . . . . . . . . . . .10076, 10077<br />

XFFR Halogen-free, flame-retardant, heat-shrinkable tubing . .10078, 10079<br />

Molded Parts<br />

Shapes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10080, 10081<br />

Shape Selection Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10082, 10083<br />

Part Numbering System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10084<br />

Visual Selection Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10085-10097<br />

Boot Adapter Selection Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10098-10100<br />

Material Selection Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10101<br />

Materials<br />

-3 Semi-rigid modified polyolefin . . . . . . . . . . . . . . . . . . . . .10102, 10103<br />

-4 Flexible polyolefin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10104, 10105<br />

-12 Modified fluoroelastomer . . . . . . . . . . . . . . . . . . . . . . . . .10106, 10107<br />

-25 Fluid-resistant modified elastomer . . . . . . . . . . . . . . . . .10108, 10109<br />

-25S Fluid-resistant screened elastomer . . . . . . . . . . . . . . . . .10110, 10111<br />

-50 Fluid-resistant modified elastomer . . . . . . . . . . . . . . . . . .10112, 10113<br />

-51 Chemical-resistant fluoroelastomer . . . . . . . . . . . . . . . . .10114, 10115<br />

-55 Flexible fluoropolymer . . . . . . . . . . . . . . . . . . . . . . . . . . .10116, 10117<br />

-71 Semi-rigid modified polyolefin . . . . . . . . . . . . . . . . . . . . .10118, 10119<br />

-100 Low-fire-hazard material . . . . . . . . . . . . . . . . . . . . . . . . .10120, 10121<br />

-100S Low-fire-hazard screened material . . . . . . . . . . . . . . . . .10122, 10123<br />

-125 Flexible fluoropolymer . . . . . . . . . . . . . . . . . . . . . . . . . . .10124, 10125<br />

Caps<br />

101A011 to 094 End caps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10126, 10127<br />

SSC Heat-shrinkable end caps . . . . . . . . . . . . . . . . . . . . . . . .10128, 10129<br />

Boots<br />

202A111 to 196 Straight boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10130<br />

202C611 to 663 Uniboot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10131<br />

202D121 to 196 Straight, lipped boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10132<br />

202D211 to 299 Straight, lipped boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10133<br />

202D921 to 963 Straight, lipped boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10134<br />

202F211 to 274 Straight, lipped boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10135<br />

202G211 to 253 Straight, low profile lipped boot . . . . . . . . . . . . . . . . . . . . . . . . . .10136<br />

202G611 to 653 Uniboot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10137<br />

202K121 to 185 Straight, lipped boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10138<br />

214A011 to 052 D-subminiature, straight boot . . . . . . . . . . . . . . . . . . . . . . . . . . .10139<br />

214A311 to 352 D-subminiature, straight boot . . . . . . . . . . . . . . . . . . . . . . . . . . .10140<br />

214P009 to 037 D-subminiature, straight boot with jack screws . . . . . . . . . . . . . .10141<br />

Catalog 1308940 Dimensions are in millimeters Dimensions are shown for USA: 1-800-522-6752 South America: 55-11-3611-1514<br />

Revised 5-03 and inches unless otherwise reference purposes only. Canada: 1-905-470-4425 Japan: 81-44-900-5102<br />

specified. Values in brackets Specifications subject Mexico: 01-800-733-8926 Singapore: 65-4866-151<br />

www.tycoelectronics.com are U.S. equivalents. to change. C. America: 52-55-5-729-0425 UK: 44-1793-528171

Heat-Shrink Tubing, Molded Parts and Adhesives<br />

Table of Contents (Continued)<br />

222A111 to 196 Right-angled boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10142<br />

222D121 to 196 Right-angled, lipped boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10143<br />

222D211 to 299 Right-angled, lipped boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10144<br />

222D921 to 963 Right-angled, lipped boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10145<br />

222F211 to 285 Right-angled, lipped boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10146<br />

222K121 to 185 Right-angled, lipped boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10147<br />

234A011 to 071 D-subminiature, right-angled boot . . . . . . . . . . . . . . . . . . . . . . . .10148<br />

234A111 to 152 D-subminiature, side-entry boot . . . . . . . . . . . . . . . . . . . . . . . . .10149<br />

234A611 to 671 D-subminiature, 90˚ end-entry boot . . . . . . . . . . . . . . . . . . . . . .10150<br />

242W042 to 63 45˚ angled boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10151<br />

Feedthroughs<br />

207W213 to 256 Two-part feedthrough . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10152<br />

Transition<br />

301A011 to 048 T transition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10153<br />

301A511 to 514 Slimline T transition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10154<br />

322A112 to 158 T transition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10155<br />

342A012 to 058 45˚ side-breakout transition . . . . . . . . . . . . . . . . . . . . . . . . . . . .10156<br />

362A014 to 114 30˚ side-breakout transition . . . . . . . . . . . . . . . . . . . . . . . . . . . .10157<br />

381A301 to 304 Slimline Y transition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10158<br />

382A012 to 046 Y transition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10159<br />

382C312, Slimline Y transition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10160<br />

322 & 332<br />

462A011 to 060 Transition, one to three cables . . . . . . . . . . . . . . . . . . . . . . . . . .10161<br />

462A421 to 424 Slimline transition, one to three cables . . . . . . . . . . . . . . . . . . . .10162<br />

562A011 to 067 Transition, one to four cables . . . . . . . . . . . . . . . . . . . . . . . . . . .10163<br />

QFT Configurable heat-shrink transition . . . . . . . . . . . . . . . . .10164, 10165<br />

SSB, T, F to 8S Multilegged transitions . . . . . . . . . . . . . . . . . . . . . . . . . .10166, 10167<br />

Accessories<br />

202W302 to 342 <strong>Heatshrink</strong> bobbins . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10168, 10169<br />

400W242 <strong>Heatshrink</strong><br />

positioning ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10170, 10171<br />

CES<br />

Heat-shrinkable<br />

cable entry seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10172-10175<br />

RayOLOn Kits Roll-on sealing sleeve . . . . . . . . . . . . . . . . . . . . . . . . . . .10176, 10177<br />

shrinkHOoP Cable clamp<br />

heat-shrink grommet . . . . . . . . . . . . . . . . . . . . . . . . . . . .10178-10180<br />

XL <strong>Products</strong> Conversion Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10181, 10182<br />

Adhesives<br />

Selection Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10183<br />

Adhesive/Sealant Product Characteristics Tables . . . . . . . . . . . . . . . . . . . . . .10184, 10185<br />

Installation Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10186-10188<br />

Application Tooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10189-10204<br />

10<br />

Heat-Shrink Tubing,<br />

Molded Parts and Adhesives<br />

Catalog 1308940 Dimensions are in millimeters Dimensions are shown for USA: 1-800-522-6752 South America: 55-11-3611-1514<br />

Revised 5-03 and inches unless otherwise reference purposes only. Canada: 1-905-470-4425 Japan: 81-44-900-5102<br />

specified. Values in brackets Specifications subject Mexico: 01-800-733-8926 Singapore: 65-4866-151<br />

www.tycoelectronics.com are U.S. equivalents. to change. C. America: 52-55-5-729-0425 UK: 44-1793-528171<br />

10003

Single-Wall Tubing<br />

CRN<br />

Semi-rigid,<br />

Flame-Retardant,<br />

Polyolefin Tubing<br />

Product Facts<br />

■ 2:1 shrink ratio<br />

■ High abrasion resistance<br />

■ Transfer of flex stress away<br />

from typically weak points<br />

such as solder and crimp<br />

joints, helping ensure a<br />

reliable connection<br />

■ Flame-retardance (colors<br />

only)<br />

■ Outstanding physical and<br />

electrical performance<br />

■ Excellent chemical and<br />

solvent-resistance<br />

properties<br />

Applications<br />

Ideally suited for wire strainrelief<br />

applications such as<br />

soldered or crimped connections,<br />

wire splices, and<br />

terminations. Provides<br />

mechanical protection for<br />

delicate components. Can<br />

be used for component<br />

packaging and for rugged<br />

marking of cables.<br />

Installation<br />

Minimum shrink temperature:<br />

110°C [230°F]<br />

Minimum full recovery<br />

temperature: 135°C [275°F]<br />

Operating Temperature Range<br />

-55°C to 135°C<br />

[-67°F to 275°F]<br />

Specifications/Approvals<br />

Series<br />

®<br />

Military <strong>Raychem</strong><br />

®<br />

CRN Type 1 E35586 LR31929 AMS-DTL-23053/6*, Class l RT-360, Type 1<br />

(colors) 600 V, 125°C (black only) Def. Stan. 59-97 Type 2C RK-6003<br />

[257°F] 600 V, 125°C (not red)<br />

[257°F]<br />

CRN Type 2 (clear) — — AMS-DTL-23053/6*, Class 2 RT-360, Type 2<br />

*Formerly MIL-I-23053/6 and MIL-DTL-23053/6.<br />

10004<br />

Catalog 1308940 Dimensions are in millimeters Dimensions are shown for USA: 1-800-522-6752 South America: 55-11-3611-1514<br />

Revised 5-03 and inches unless otherwise reference purposes only. Canada: 1-905-470-4425 Japan: 81-44-900-5102<br />

specified. Values in brackets Specifications subject Mexico: 01-800-733-8926 Singapore: 65-4866-151<br />

www.tycoelectronics.com are U.S. equivalents. to change. C. America: 52-55-5-729-0425 UK: 44-1793-528171

Single-Wall Tubing<br />

CRN (Continued)<br />

Product Dimensions<br />

Inside Diameter<br />

Recovered Wall<br />

Size Minimum Expanded Maximum Recovered Thickness**<br />

as Supplied After Heating After Heating<br />

3/64 1.2 [0.046] 0.6 [0.023] 0.51 ± 0.08 [0.020 ± 0.003]<br />

1/16 1.6 [0.063] 0.8 [0.031] 0.51 ± 0.08 [0.020 ± 0.003]<br />

3/32 2.4 [0.093] 1.2 [0.046] 0.51 ± 0.08 [0.020 ± 0.003]<br />

1/8 3.2 [0.125] 1.6 [0.062] 0.51 ± 0.08 [0.020 ± 0.003]<br />

3/16 4.8 [0.187] 2.4 [0.093] 0.64 ± 0.08 [0.025 ± 0.003]<br />

1/4 6.4 [0.250] 3.2 [0.125] 0.64 ± 0.08 [0.025 ± 0.003]<br />

3/8 9.5 [0.375] 4.8 [0.187] 0.76 ± 0.08 [0.030 ± 0.003]<br />

1/2 12.7 [0.500] 6.4 [0.250] 0.76 ± 0.08 [0.030 ± 0.003]<br />

3/4 19.1 [0.750] 9.5 [0.375] 0.89 ± 0.12 [0.035 ± 0.005]<br />

**Wall thickness will be less if tubing recovery is restricted during shrinkage.<br />

Ordering Information<br />

Standard Black (-0)<br />

Color<br />

Nonstandard<br />

White (-9), red (-2), blue (-6), yellow (-4), green (-5), brown (-1),<br />

orange (-3), violet (-7), gray (-8), clear (-X, not flame-retardant)<br />

Always order the largest size that will shrink snugly over the<br />

Size selection<br />

component to be covered.<br />

Special order sizes are available upon request.<br />

Standard packaging In 1.2-meter [4-foot] lengths.<br />

Ordering description*** Specify product name, size and color (for example, CRN 1/4-0).<br />

***Europe only. For supply to MIL, Def Stan and BS add -MS, -DS or -BS to ordering description.<br />

10<br />

Heat-Shrink Tubing,<br />

Molded Parts and Adhesives<br />

Catalog 1308940 Dimensions are in millimeters Dimensions are shown for USA: 1-800-522-6752 South America: 55-11-3611-1514<br />

Revised 5-03 and inches unless otherwise reference purposes only. Canada: 1-905-470-4425 Japan: 81-44-900-5102<br />

specified. Values in brackets Specifications subject Mexico: 01-800-733-8926 Singapore: 65-4866-151<br />

www.tycoelectronics.com are U.S. equivalents. to change. C. America: 52-55-5-729-0425 UK: 44-1793-528171<br />

10005

Single-Wall Tubing<br />

DCPT<br />

Flexible, Flame-Retardant,<br />

Dual-Color, Polyolefin<br />

Tubing<br />

Product Facts<br />

■ 2:1 and 3:1 shrink ratio<br />

■ Dual colors (yellow/green)<br />

for instant identification<br />

■ Co-extrusion of tubing<br />

colors, giving color<br />

permanence superior to that<br />

of conventional ink marking<br />

■ Flame-retardance<br />

■ Flexibility: able to conform<br />

to irregular shapes<br />

■ Excellent physical,<br />

chemical, and electrical<br />

properties that meet industry<br />

standards for highly<br />

reliable, general purpose<br />

tubing<br />

Applications<br />

Used to identify “ground” on<br />

wires and in cables, and to<br />

jacket and insulate lightduty<br />

harnesses.<br />

Easily marked by conventional<br />

techniques for additional<br />

identification of wire<br />

and cable.<br />

Installation<br />

Minimum shrink temperature:<br />

95°C [203°F]<br />

Minimum full recovery<br />

temperature: 120°C [248°F]<br />

Operating Temperature Range<br />

-55°C to 135°C<br />

[-67°F to 275°F]<br />

Specifications/Approvals<br />

®<br />

Series Military Agency <strong>Raychem</strong><br />

®<br />

DCPT E35586 LR31929 Def Stan 59-97 Issue 3 Type 2B AFS 2270 RW-2056<br />

600 V, 125°C 600 V, 125°C VG 95343 Pt 5 Type A DIN 29807<br />

[257°F] [257°F] VDE 0341<br />

Pt 9005 Type A<br />

10006<br />

Catalog 1308940 Dimensions are in millimeters Dimensions are shown for USA: 1-800-522-6752 South America: 55-11-3611-1514<br />

Revised 5-03 and inches unless otherwise reference purposes only. Canada: 1-905-470-4425 Japan: 81-44-900-5102<br />

specified. Values in brackets Specifications subject Mexico: 01-800-733-8926 Singapore: 65-4866-151<br />

www.tycoelectronics.com are U.S. equivalents. to change. C. America: 52-55-5-729-0425 UK: 44-1793-528171

Single-Wall Tubing<br />

DCPT (Continued)<br />

Product Dimensions<br />

2:1<br />

Inside Diameter<br />

Recovered Wall<br />

Size Minimum Expanded Maximum Recovered Thickness**<br />

as Supplied After Heating After Heating<br />

3/1.5 3 [0.118] 1.5 [0.059] 0.51 ± 0.10 [0.020 ± 0.004]<br />

6/3 6 [0.236] 3.0 [0.118] 0.58 ± 0.10 [0.025 ± 0.004]<br />

8/4 8 [0.315] 4.0 [0.158] 0.64 ± 0.10 [0.025 ± 0.004]<br />

10/5 10 [0.394] 5.0 [0.197] 0.64 ± 0.10 [0.025 ± 0.004]<br />

12/6 12 [0.472] 6.0 [0.236] 0.64 ± 0.10 [0.025 ± 0.004]<br />

19/9 19 [0.748] 9.0 [0.354] 0.76 ± 0.12 [0.030 ± 0.005]<br />

26/13 26 [1.024] 13.0 [0.512] 0.89 ± 0.12 [0.035 ± 0.005]<br />

38/19 38 [1.500] 19.0 [0.748] 1.00 ± 0.12 [0.039 ± 0.005]<br />

51/19 51 [2.000] 19.0 [0.748] 1.02 ± 0.15 [0.040 ± 0.006]<br />

3:1 (Europe only)<br />

3/1 3.0 [0.118] 1.0 [0.039] 0.55 ± 0.10 [0.022 ± 0.004]<br />

6/2 6.0 [0.236] 2.0 [0.079] 0.65 ± 0.10 [0.026 ± 0.004]<br />

9/3 9.0 [0.354] 3.0 [0.118] 0.75 ± 0.15 [0.030 ± 0.006]<br />

12/4 12.0 [0.472] 4.0 [0.157] 0.75 ± 0.15 [0.030 ± 0.006]<br />

18/6 18.0 [0.709] 6.0 [0.236] 0.85 ± 0.15 [0.033 ± 0.006]<br />

24/8 24.0 [0.945] 8.0 [0.315] 1.00 ± 0.20 [0.039 ± 0.008]<br />

*Wall thickness will be less if tubing recovery is restricted during shrinkage.<br />

Ordering Information<br />

Color Standard Yellow/green stripe (-45)<br />

Size selection Always order the largest size that will shrink snugly over the component to be covered.<br />

Special order sizes are available upon request.<br />

Standard packaging On spools.<br />

Ordering description** Specify product name, size and color (for example, DCPT 8/4-45).<br />

**Europe only. For supply to Def Stan and BS add -DS or -BS to ordering description.<br />

10<br />

Heat-Shrink Tubing,<br />

Molded Parts and Adhesives<br />

Catalog 1308940 Dimensions are in millimeters Dimensions are shown for USA: 1-800-522-6752 South America: 55-11-3611-1514<br />

Revised 5-03 and inches unless otherwise reference purposes only. Canada: 1-905-470-4425 Japan: 81-44-900-5102<br />

specified. Values in brackets Specifications subject Mexico: 01-800-733-8926 Singapore: 65-4866-151<br />

www.tycoelectronics.com are U.S. equivalents. to change. C. America: 52-55-5-729-0425 UK: 44-1793-528171<br />

10007

Single-Wall Tubing<br />

DR-25<br />

Heat-Shrinkable, Flexible,<br />

Chemical and Abrasion<br />

Resistant Tubing<br />

Product Facts<br />

■ Flame-retardant<br />

■ System-25 tubing<br />

■ Shrink ratio 2:1<br />

Applications<br />

Specially formulated for<br />

optimum high temperature<br />

fluid resistance, and long<br />

term heat resistance.<br />

Resistant to aviation and<br />

diesel fuels, hydraulic fluids<br />

and lubricating oils.<br />

Particularly suitable as a<br />

jacketing material for military<br />

ground vehicle cables<br />

and harnesses. It is also<br />

ideally suited for the<br />

demands of motorsport<br />

cable harnesses. When<br />

used in conjunction with<br />

System 25 heat-shrinkable<br />

molded shapes and S1125<br />

high performance adhesive,<br />

these products provide a<br />

complete cable harness<br />

system.<br />

Installation<br />

Minimum full recovery<br />

temperature: 175°C [347°F]<br />

Operating Temperature Range<br />

-75°C to 150°C<br />

[-103°F to 302°F]<br />

(per VG 95343 Part 5<br />

Type D)<br />

Specifications/Approvals<br />

Series Military <strong>Raychem</strong><br />

DR-25 AMS-DTL-23053/16* RT-1116<br />

VG95343 Part 5 Type D RK 6008/1<br />

VDE 0341/Pt 9005<br />

Def Stan 59-97 Issue 3 Type 6B<br />

BS 4G-198 Part 3 10A<br />

*Formerly MIL-I-23053/16 and MIL-DTL-23053/16.<br />

10008<br />

Catalog 1308940 Dimensions are in millimeters Dimensions are shown for USA: 1-800-522-6752 South America: 55-11-3611-1514<br />

Revised 5-03 and inches unless otherwise reference purposes only. Canada: 1-905-470-4425 Japan: 81-44-900-5102<br />

specified. Values in brackets Specifications subject Mexico: 01-800-733-8926 Singapore: 65-4866-151<br />

www.tycoelectronics.com are U.S. equivalents. to change. C. America: 52-55-5-729-0425 UK: 44-1793-528171

Single-Wall Tubing<br />

DR-25 (Continued)<br />

Product Dimensions<br />

Inside Diameter<br />

Recovered<br />

Size Minimum Expanded Maximum Recovered Wall Thickness**<br />

as Supplied After Heating After Heating<br />

1/8 3.2 [0.125] 1.6 [0.063] 0.76 ± 0.15 [0.030 ± 0.006]<br />

3/16 4.8 [0.187] 2.4 [0.093] 0.84 ± 0.15 [0.033 ± 0.006]<br />

1/4 6.4 [0.250] 3.2 [0.125] 0.89 ± 0.15 [0.035 ± 0.006]<br />

3/8 9.5 [0.375] 4.8 [0.187] 1.02 ± 0.20 [0.040 ± 0.008]<br />

1/2 12.7 [0.500] 6.4 [0.250] 1.22 ± 0.20 [0.048 ± 0.008]<br />

3/4 19.0 [0.748] 9.5 [0.375] 1.45 ± 0.28 [0.057 ± 0.011]<br />

1 25.4 [1.000] 12.7 [0.500] 1.78 ± 0.28 [0.070 ± 0.011]<br />

1 1/2 38.0 [1.500] 19.0 [0.748] 2.41 ± 0.41 [0.095 ± 0.016]<br />

2 51.0 [2.000] 25.4 [1.000] 2.79 ± 0.41 [0.110 ± 0.016]<br />

3 76.0 [3.000] 38.0 [1.500] 3.18 ± 0.50 [0.125 ± 0.020]<br />

**Wall thickness will be less if tubing recovery is restricted during shrinkage.<br />

Ordering Information<br />

Color Standard Black (-0)<br />

Size selection<br />

Always order the largest size that will shrink snugly over the component to be covered.<br />

Special order sizes are available upon request.<br />

Standard packaging On spools.<br />

Ordering description*** Specify product name, size and color (for example, DR-25-1/8-0)<br />

***Europe only. For supply to Def Stan and BS add -DS or -BS to ordering description.<br />

10<br />

Heat-Shrink Tubing,<br />

Molded Parts and Adhesives<br />

Catalog 1308940 Dimensions are in millimeters Dimensions are shown for USA: 1-800-522-6752 South America: 55-11-3611-1514<br />

Revised 5-03 and inches unless otherwise reference purposes only. Canada: 1-905-470-4425 Japan: 81-44-900-5102<br />

specified. Values in brackets Specifications subject Mexico: 01-800-733-8926 Singapore: 65-4866-151<br />

www.tycoelectronics.com are U.S. equivalents. to change. C. America: 52-55-5-729-0425 UK: 44-1793-528171<br />

10009

Single-Wall Tubing<br />

MicroFit<br />

Small-diameter,<br />

high-shrink-ratio tubing<br />

Product Facts<br />

■ Small diameter<br />

■ High shrink ratio<br />

■ Thin wall<br />

■ Polyolefin and fluoropolymer<br />

materials<br />

Applications<br />

The MicroFit family of smalldiameter,<br />

high-shrink-ratio<br />

tubing is ideal for electrical<br />

insulation, mechanical protection,<br />

and strain relief in<br />

smaller, more compact<br />

medical devices and commercial<br />

electronics products.<br />

Offered in a variety of<br />

materials. The RW-175 version<br />

of MicroFit tubing is<br />

suitable for use in space<br />

applications.<br />

Installation<br />

Minimum full recovery<br />

temperature:<br />

175°C [347°F] (MT1000)<br />

140°C [284°F] (MT2000)<br />

175°C [347°F] (RW-175)<br />

Operating Temperature Range<br />

MT1000:-55°C to 125°C<br />

[-67°F to 257°F]<br />

MT2000:-40°C to 105°C<br />

[-40°F to 221°F]<br />

RW-175: -55°C to 175°C<br />

[-67°F to 347°F]<br />

Specifications/Approvals<br />

Series Material Master File Number <strong>Raychem</strong><br />

Altera MicroFit<br />

USP Class VI (MT1000) MAF-444 (MT1000)<br />

Altera MicroFit SCD<br />

USP Class VI (MT2000) MAF-727 (MT2000)<br />

RW-175 MicroFit — — RW-175 MicroFit SCD<br />

10010<br />

Catalog 1308940 Dimensions are in millimeters Dimensions are shown for USA: 1-800-522-6752 South America: 55-11-3611-1514<br />

Revised 5-03 and inches unless otherwise reference purposes only. Canada: 1-905-470-4425 Japan: 81-44-900-5102<br />

specified. Values in brackets Specifications subject Mexico: 01-800-733-8926 Singapore: 65-4866-151<br />

www.tycoelectronics.com are U.S. equivalents. to change. C. America: 52-55-5-729-0425 UK: 44-1793-528171

Single-Wall Tubing<br />

MicroFit (Continued)<br />

Product Dimensions<br />

Inside Diameter<br />

Wall Thickness<br />

Minimum Maximum<br />

Size<br />

As Supplied Recovered***<br />

Expanded Recovered<br />

(Nominal) (Maximum)<br />

as Supplied After Heating<br />

MFT-*-No. 1-** 0.356 [0.014] 0.178 [0.007] 0.076 [0.003] 0.127 [0.005]<br />

MFT-*-No. 2-** 0.610 [0.024] 0.305 [0.012] 0.064 [0.0025] 0.152 [0.006]<br />

MFT-*-No. 33-** 1.143 [0.045] 0.432 [0.017] 0.064 [0.0025] 0.178 [0.007]<br />

MFT-*-No. 65-** 0.635 [0.025] 0.254 [0.010] 0.127 [0.005] 0.330 [0.013]<br />

*Replace single asterisk with material type: MT1000, MT2000, or RW-175.<br />

**Replace double asterisk with color-code number.<br />

***Wall thickness will be less if tubing recovery is restricted during shrinkage.<br />

Ordering Information<br />

MT1000 MT2000 RW-175<br />

Standard Translucent (-X) Black (-0), clear (-X) Translucent (-X)<br />

Color<br />

Nonstandard Black (-0)<br />

White (-9), red (-2), yellow (-4),<br />

blue (-6), orange (-3)<br />

Black (-0)<br />

Size selection<br />

Always order the largest size that will shrink snugly over the component to be covered.<br />

Special order sizes are available upon request.<br />

Standard packaging On plastic spools****<br />

Ordering description Specify product name, material, size and color (for example, MFT-MT2000-No. 1-0).<br />

****MFT-MT1000 and MFT-MT2000 are double bagged.<br />

10<br />

Heat-Shrink Tubing,<br />

Molded Parts and Adhesives<br />

Catalog 1308940 Dimensions are in millimeters Dimensions are shown for USA: 1-800-522-6752 South America: 55-11-3611-1514<br />

Revised 5-03 and inches unless otherwise reference purposes only. Canada: 1-905-470-4425 Japan: 81-44-900-5102<br />

specified. Values in brackets Specifications subject Mexico: 01-800-733-8926 Singapore: 65-4866-151<br />

www.tycoelectronics.com are U.S. equivalents. to change. C. America: 52-55-5-729-0425 UK: 44-1793-528171<br />

10011

Single-Wall Tubing<br />

NT/NTFR<br />

Very Flexible, Rugged<br />

Neoprene Elastomer Tubing<br />

Product Facts<br />

■ Remains flexible at low<br />

temperatures without<br />

cracking<br />

■ Offers outstanding<br />

resistance to abrasion and<br />

physical abuse while<br />

providing the flexibility and<br />

strain relief needed for<br />

rugged applications<br />

■ Resistant to most fluids and<br />

solvents, including aviation<br />

and ground-vehicle fuels,<br />

lubricating oil, and hydraulic<br />

fluids (see <strong>Raychem</strong><br />

Specification RT-511,<br />

RT-510)<br />

■ System 20<br />

Applications<br />

Widely used for insulation,<br />

strain relief, and abrasion<br />

protection on cable harnesses<br />

and wire bundles in<br />

the military and aerospace<br />

industries. Especially suitable<br />

for applications requiring<br />

exposure to fluids and<br />

solvents at elevated<br />

temperatures.<br />

Installation<br />

Minimum shrink temperature:<br />

90°C [194°F]<br />

Minimum full recovery<br />

temperature: 135°C [275°F]<br />

Operating Temperature Range<br />

-70°C to 121°C<br />

[-94°F to 250°F]<br />

Specifications/Approvals<br />

®<br />

Series Military Agency <strong>Raychem</strong><br />

®<br />

UL E35586 CSA LR31929<br />

NT 600V, 90°C 600V, 90°C [194°F] — — RT-510<br />

[194°F]<br />

NTFR — — SC-X-15112 AMS 3623 RT-511<br />

*Formerly MIL-I-23053/1 and MIL-DTL-23053/1.<br />

10012<br />

Catalog 1308940 Dimensions are in millimeters Dimensions are shown for USA: 1-800-522-6752 South America: 55-11-3611-1514<br />

Revised 5-03 and inches unless otherwise reference purposes only. Canada: 1-905-470-4425 Japan: 81-44-900-5102<br />

specified. Values in brackets Specifications subject Mexico: 01-800-733-8926 Singapore: 65-4866-151<br />

www.tycoelectronics.com are U.S. equivalents. to change. C. America: 52-55-5-729-0425 UK: 44-1793-528171

Single-Wall Tubing<br />

NT/NTFR (Continued)<br />

Product Dimensions<br />

Inside Diameter<br />

Recovered Wall<br />

Size Minimum Expanded Maximum Recovered Thickness**<br />

as Supplied After Heating After Heating<br />

1/8 3.2 [0.125] 1.6 [0.061] 0.69 ± 0.20 [0.027 ± 0.008]<br />

3/16 4.8 [0.187] 2.6 [0.100] 0.84 ± 0.25 [0.033 ± 0.010]<br />

1/4 6.4 [0.250] 3.6 [0.143] 0.88 ± 0.25 [0.035 ± 0.010]<br />

3/8 9.5 [0.375] 5.5 [0.214] 1.02 ± 0.25 [0.040 ± 0.010]<br />

1/2 12.7 [0.500] 7.3 [0.286] 1.21 ± 0.38 [0.048 ± 0.015]<br />

5/8 15.9 [0.625] 9.1 [0.357] 1.32 ± 0.38 [0.052 ± 0.015]<br />

3/4 19.1 [0.750] 10.9 [0.428] 1.44 ± 0.38 [0.057 ± 0.015]<br />

7/8 22.2 [0.875] 12.7 [0.500] 1.65 ± 0.38 [0.065 ± 0.015]<br />

1 25.4 [1.000] 14.5 [0.570] 1.77 ± 0.50 [0.070 ± 0.020]<br />

1 1/4 31.8 [1.250] 18.1 [0.714] 2.20 ± 0.50 [0.087 ± 0.020]<br />

1 1/2 38.1 [1.500] 21.8 [0.857] 2.41 ± 0.50 [0.095 ± 0.020]<br />

1 3/4 44.5 [1.750] 25.4 [1.000] 2.71 ± 0.50 [0.107 ± 0.020]<br />

2 50.8 [2.000] 29.0 [1.140] 2.79 ± 0.50 [0.110 ± 0.020]<br />

3 76.2 [3.000] 43.4 [1.710] 3.18 ± 0.50 [0.125 ± 0.020]<br />

**Wall thickness will be less if tubing recovery is restricted during shrinkage.<br />

Ordering Information<br />

Color Standard Black (-0)<br />

Size selection<br />

Always order the largest size that will shrink snugly over the component to be covered.<br />

Special order sizes are available upon request.<br />

Standard packaging On spools.<br />

Ordering description Specify product name, size and color (for example, NTFR 1/4-0).<br />

10<br />

Heat-Shrink Tubing,<br />

Molded Parts and Adhesives<br />

Catalog 1308940 Dimensions are in millimeters Dimensions are shown for USA: 1-800-522-6752 South America: 55-11-3611-1514<br />

Revised 5-03 and inches unless otherwise reference purposes only. Canada: 1-905-470-4425 Japan: 81-44-900-5102<br />

specified. Values in brackets Specifications subject Mexico: 01-800-733-8926 Singapore: 65-4866-151<br />

www.tycoelectronics.com are U.S. equivalents. to change. C. America: 52-55-5-729-0425 UK: 44-1793-528171<br />

10013

Single-Wall Tubing<br />

NT-MIL<br />

Flexible, Rugged, Modified<br />

Elastomeric Heat-<br />

Shrinkable Tubing<br />

Product Facts<br />

■ Offers outstanding<br />

resistance to abrasion and<br />

physical abuse while<br />

providing flexibility and<br />

strain relief needed in many<br />

harnessing applications<br />

■ Remains flexible at low<br />

temperatures without<br />

cracking<br />

■ Withstands heat shock at<br />

200°C [392°F] without<br />

dripping, flowing or<br />

cracking<br />

■ Resistant to common fluids<br />

and solvents, including<br />

aviation and ground vehicle<br />

fuels, lubricating oil, and<br />

hydraulic fluids<br />

■ Retains physical and<br />

electrical properties<br />

following exposure<br />

Applications<br />

Installation<br />

Operating Temperature Range<br />

Widely used for insulation,<br />

strain relief and abrasion<br />

protection on cable harnesses<br />

and wire bundles in<br />

the military and aerospace<br />

industries.<br />

Minimum full recovery<br />

temperature: 135°C [275°F]<br />

-70°C to 121°C<br />

[-94°F to 250°F]<br />

Specifications/Approvals<br />

Series Military <strong>Raychem</strong><br />

NT-MIL AMS-DTL-23053/1, Class 1 & 2 RW-3030<br />

10014<br />

Catalog 1308940 Dimensions are in millimeters Dimensions are shown for USA: 1-800-522-6752 South America: 55-11-3611-1514<br />

Revised 5-03 and inches unless otherwise reference purposes only. Canada: 1-905-470-4425 Japan: 81-44-900-5102<br />

specified. Values in brackets Specifications subject Mexico: 01-800-733-8926 Singapore: 65-4866-151<br />

www.tycoelectronics.com are U.S. equivalents. to change. C. America: 52-55-5-729-0425 UK: 44-1793-528171

Single-Wall Tubing<br />

NT-MIL (Continued)<br />

Product Dimensions<br />

Inside Diameter<br />

Recovered Wall<br />

Size Minimum Expanded Maximum Recovered Thickness*<br />

as Supplied After Heating After Heating<br />

1/8 3.2 [0.125] 1.6 [0.062] 0.66 ± 0.20 [0.026 ± 0.008]<br />

3/16 4.8 [0.187] 2.4 [0.093] 0.84 ± 0.25 [0.033 ± 0.010]<br />

1/4 6.4 [0.250] 3.6 [0.143] 0.89 ± 0.25 [0.035 ± 0.010]<br />

3/8 9.5 [0.375] 5.4 [0.211] 1.01 ± 0.25 [0.040 ± 0.010]<br />

1/2 12.7 [0.500] 7.3 [0.286] 1.21 ± 0.38 [0.048 ± 0.015]<br />

5/8 15.9 [0.625] 9.1 [0.357] 1.32 ± 0.38 [0.052 ± 0.015]<br />

3/4 19.1 [0.750] 10.9 [0.428] 1.44 ± 0.38 [0.057 ± 0.015]<br />

7/8 22.2 [0.875] 12.7 [0.500] 1.65 ± 0.38 [0.065 ± 0.015]<br />

1 25.4 [1.000] 14.5 [0.570] 1.77 ± 0.51 [0.070 ± 0.020]<br />

1 1/4 31.8 [1.250] 18.1 [0.714] 2.20 ± 0.51 [0.087 ± 0.020]<br />

1 1/2 38.1 [1.500] 21.8 [0.857] 2.41 ± 0.51 [0.095 ± 0.020]<br />

1 3/4 44.5 [1.750] 25.4 [1.000] 2.71 ± 0.51 [0.107 ± 0.020]<br />

2 50.8 [2.000] 29.0 [1.140] 2.79 ± 0.51 [0.110 ± 0.020]<br />

3 76.2 [3.000] 43.4 [1.710] 3.17 ± 0.51 [0.125 ± 0.020]<br />

4 101.6 [4.000] 57.9 [2.280] 3.55 ± 0.51 [0.140 ± 0.020]<br />

*Wall thickness will be less if tubing recovery is restricted during shrinkage.<br />

Ordering Information<br />

Color Standard Black (-0)<br />

Size selection<br />

Always order the largest size that will shrink snugly over the component to be covered.<br />

Standard packaging On spools.<br />

Ordering description Specify product name, size and color (for example, NT-MIL 1/4-0 (0 = Black).<br />

10<br />

Heat-Shrink Tubing,<br />

Molded Parts and Adhesives<br />

Catalog 1308940 Dimensions are in millimeters Dimensions are shown for USA: 1-800-522-6752 South America: 55-11-3611-1514<br />

Revised 5-03 and inches unless otherwise reference purposes only. Canada: 1-905-470-4425 Japan: 81-44-900-5102<br />

specified. Values in brackets Specifications subject Mexico: 01-800-733-8926 Singapore: 65-4866-151<br />

www.tycoelectronics.com are U.S. equivalents. to change. C. America: 52-55-5-729-0425 UK: 44-1793-528171<br />