26 29 23-001A Med Voltage VFD Resubmittal - Garney Construction

26 29 23-001A Med Voltage VFD Resubmittal - Garney Construction

26 29 23-001A Med Voltage VFD Resubmittal - Garney Construction

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

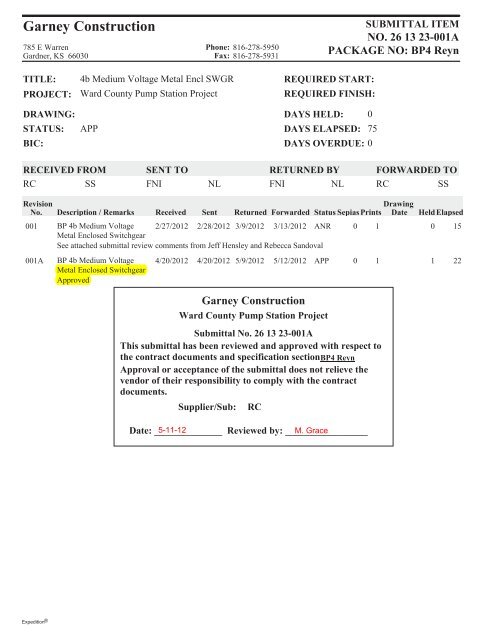

<strong>Garney</strong> <strong>Construction</strong><br />

785 E Warren<br />

Gardner, KS 66030<br />

Phone: 816-278-5950<br />

Fax: 816-278-5931<br />

SUBMITTAL ITEM<br />

O. <strong>26</strong> 13 <strong>23</strong>-<strong>001A</strong><br />

PACKAGE O: BP4 Reyn<br />

TITLE:<br />

PROJECT:<br />

DRAWIG:<br />

STATUS:<br />

BIC:<br />

4b <strong>Med</strong>ium <strong>Voltage</strong> Metal Encl SWGR<br />

Ward County Pump Station Project<br />

APP<br />

REQUIRED START:<br />

REQUIRED FIISH:<br />

DAYS HELD: 0<br />

DAYS ELAPSED: 75<br />

DAYS OVERDUE: 0<br />

RECEIVED FROM<br />

RC<br />

SS<br />

SET TO<br />

FNI<br />

NL<br />

RETURED BY<br />

FNI NL<br />

FORWARDED TO<br />

RC<br />

SS<br />

Revision<br />

o.<br />

Description / Remarks<br />

Received<br />

Sent<br />

Drawing<br />

Returned Forwarded Status Sepias Prints Date HeldElapsed<br />

001 BP 4b <strong>Med</strong>ium <strong>Voltage</strong><br />

Metal Enclosed Switchgear<br />

2/27/2012 2/28/2012 3/9/2012 3/13/2012 ANR 0 1 0 15<br />

See attached submittal review comments from Jeff Hensley and Rebecca Sandoval<br />

<strong>001A</strong><br />

BP 4b <strong>Med</strong>ium <strong>Voltage</strong><br />

Metal Enclosed Switchgear<br />

Approved<br />

4/20/2012 4/20/2012 5/9/2012 5/12/2012 APP 0 1 1 22<br />

<strong>Garney</strong> <strong>Construction</strong><br />

Ward County Pump Station Project<br />

Submittal o. <strong>26</strong> 13 <strong>23</strong>-<strong>001A</strong><br />

This submittal has been reviewed and approved with respect to<br />

the contract documents and specification sectionBP4 Reyn<br />

Approval or acceptance of the submittal does not relieve the<br />

vendor of their responsibility to comply with the contract<br />

documents.<br />

Supplier/Sub: RC<br />

Date: ______________ 5-11-12 Reviewed by: _________________<br />

M. Grace<br />

Expedition ®

SUBMITTALS<br />

https://projectdox.freese.com/imarkupwg/form.aspformid=6415&wfdirect=&debug=&co...<br />

Page 1 of 2<br />

5/11/2012<br />

Project No:<br />

Project:<br />

Client:<br />

Contractor:<br />

CMD11<strong>26</strong>9D<br />

CMAR Ward County Transmission System - Electrical<br />

Equipment<br />

Colorado River Municipal Water District<br />

<strong>Garney</strong><br />

Shop Drawing #<strong>001A</strong><br />

<strong>Resubmittal</strong> - <strong>Med</strong>ium <strong>Voltage</strong> Metal Enclosed Switchgear<br />

WORKFLOW COMPLETED 5/9/2012 7:38 AM<br />

SUBMITTAL INFORMATION<br />

SUBMITTAL<br />

TYPE:<br />

SUBMITTAL #: CONTRACTOR REF #: SPEC SECTION: PLAN SHEET: SUBMITTAL STATUS:<br />

Shop<br />

Drawing<br />

<strong>001A</strong><br />

SD-10 Approved<br />

SUBMITTAL<br />

DESCRIPTION:<br />

<strong>Resubmittal</strong> - <strong>Med</strong>ium <strong>Voltage</strong> Metal Enclosed Switchgear<br />

UPLOAD SUPPORTING DOCUMENTS<br />

SD-<strong>001A</strong> <strong>Resubmittal</strong> - <strong>Med</strong>ium <strong>Voltage</strong> Metal Enclosed Switchgear.pdf<br />

4/<strong>23</strong>/2012 8:25 AM Jane Jenks<br />

CONTRACTOR CERTIFICATION<br />

CONTRACTOR COMMENTS:<br />

Submitted via e-mail<br />

HOW WILL THE COPIES BE SUBMITTED:<br />

Electronic<br />

NUMBER OF COPIES SUBMITTED: 1<br />

This shop drawing has been reviewed by the Contractor and certified to be in strict conformance with the Contract Documents as modified by addenda, field orders, and<br />

change orders. Deviations can only be approved by field order or change order. Approval is only for conformance with the design concept of the project and compliance<br />

with the intent of the information given in the Contract Documents. Contractor is responsible for dimensions to be confirmed and correlated at the job site; for information<br />

that pertains solely to the fabrication processes or to techniques of construction; and for the work of all trades.<br />

SUBMITTED BY: Jane Jenks<br />

DATE: 4/<strong>23</strong>/2012 8:25 AM<br />

REVIEWER COMMENTS<br />

REVIEWER NAME: REVIEWER EMAIL: COMPANY / ORGANIZATION DATE SENT: DATE<br />

COMPLETED:<br />

Jeff Hensley<br />

jnh@freese.com<br />

4055 International Plaza<br />

4/<strong>23</strong>/2012 5/7/2012<br />

REVIEWER<br />

COMMENTS:<br />

Approved.<br />

REVIEWER NAME: REVIEWER EMAIL: COMPANY / ORGANIZATION DATE SENT: DATE<br />

COMPLETED:<br />

Rebecca<br />

Sandoval<br />

rs@freese.com<br />

Freese and Nichols, Inc<br />

4/<strong>23</strong>/2012<br />

5/2/2012<br />

REVIEWER<br />

COMMENTS:<br />

5/2/12<br />

Refer to Jeff Hensley for additional comments.<br />

Approved.<br />

UPLOAD SUPPORTING REVIEW DOCUMENTS<br />

DISPLAY ROUTING SLIP

SUBMITTALS<br />

https://projectdox.freese.com/imarkupwg/form.aspformid=6415&wfdirect=&debug=&co...<br />

Page 2 of 2<br />

5/11/2012<br />

Current Workflow Step: DCS Admin: Jane Jenks Workflow Initiator: Jane Jenks<br />

(Click on the Names above to Email User)<br />

FNI Forms v1.04

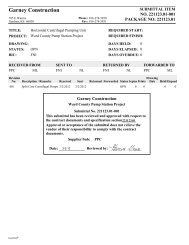

<strong>Garney</strong> <strong>Construction</strong><br />

785 E Warren<br />

Gardner, KS 66030<br />

Phone: 816-278-5950<br />

Fax: 816-278-5931<br />

SUBMITTAL ITEM<br />

O. <strong>26</strong> <strong>29</strong> <strong>23</strong>.1-<strong>001A</strong><br />

PACKAGE O: BP4 Reyn<br />

TITLE:<br />

PROJECT:<br />

DRAWIG:<br />

STATUS:<br />

BIC:<br />

4e <strong>Med</strong>ium <strong>Voltage</strong> <strong>VFD</strong>'s<br />

Ward County Pump Station Project<br />

OPN<br />

FNI<br />

REQUIRED START:<br />

REQUIRED FIISH:<br />

DAYS HELD: 0<br />

DAYS ELAPSED: 53<br />

DAYS OVERDUE: 0<br />

RECEIVED FROM<br />

RC<br />

SS<br />

SET TO<br />

FNI<br />

NL<br />

RETURED BY<br />

FNI NL<br />

FORWARDED TO<br />

RC<br />

SS<br />

Revision<br />

o.<br />

Description / Remarks<br />

Received<br />

Sent<br />

Drawing<br />

Returned Forwarded Status Sepias Prints Date HeldElapsed<br />

001 Bid Pkg 4e <strong>Med</strong>ium <strong>Voltage</strong><br />

<strong>VFD</strong>'s<br />

2/27/2012 2/28/2012 3/9/2012 3/13/2012 ANR 0 1 0 15<br />

Please address engineer's comments and resubmit entire package. Please release for fabrication and delivery per engineer's<br />

comments<br />

002 Bid Pkg 4e <strong>Med</strong>ium <strong>Voltage</strong><br />

<strong>VFD</strong>'s<br />

4/20/2012 4/20/2012 OPN 0 0 0 0<br />

Urgent <strong>Resubmittal</strong> - <strong>Garney</strong> and FNI will review concurrently.<br />

<strong>Garney</strong> <strong>Construction</strong><br />

Ward County Pump Station Project<br />

Submittal o. <strong>26</strong> <strong>29</strong> <strong>23</strong>.1-<strong>001A</strong><br />

This submittal has been reviewed and approved with respect to<br />

the contract documents and specification sectionBP4 Reyn<br />

Approval or acceptance of the submittal does not relieve the<br />

vendor of their responsibility to comply with the contract<br />

documents.<br />

Supplier/Sub: RC<br />

Date: ______________ Reviewed by: _________________<br />

Expedition ®

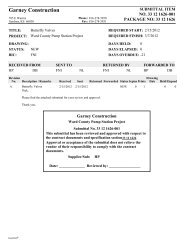

SUBMITTALS<br />

https://projectdox.freese.com/imarkupwg/form.aspformid=6415&wfdirect=&debug=&co...<br />

Page 1 of 2<br />

3/13/2012<br />

Project No:<br />

Project:<br />

Client:<br />

Contractor:<br />

CMD11<strong>26</strong>9D<br />

CMAR Ward County Transmission System - Electrical<br />

Equipment<br />

Colorado River Municipal Water District<br />

<strong>Garney</strong><br />

Shop Drawing #004<br />

URGENT Bid Package 4e <strong>Med</strong>ium <strong>Voltage</strong> <strong>VFD</strong>'s<br />

WORKFLOW COMPLETED 3/9/2012 11:<strong>29</strong> AM<br />

SUBMITTAL INFORMATION<br />

SUBMITTAL<br />

TYPE:<br />

Shop<br />

Drawing<br />

SUBMITTAL<br />

DESCRIPTION:<br />

SUBMITTAL #: CONTRACTOR REF #: SPEC SECTION: PLAN SHEET: SUBMITTAL STATUS:<br />

004<br />

<strong>26</strong> <strong>29</strong> <strong>23</strong>.01-001<br />

URGENT Bid Package 4e <strong>Med</strong>ium <strong>Voltage</strong> <strong>VFD</strong>'s<br />

<strong>26</strong> <strong>29</strong> <strong>23</strong>.01<br />

Approved As Noted, Revise<br />

and Resubmit, Additional<br />

Information Required<br />

UPLOAD SUPPORTING DOCUMENTS<br />

<strong>26</strong> <strong>29</strong> <strong>23</strong>.01 - 001.pdf 2/28/2012 7:52 PM Marcus Grace<br />

CONTRACTOR CERTIFICATION<br />

CONTRACTOR COMMENTS:<br />

Urgent Submittal - <strong>Garney</strong> and FNI will review concurrently<br />

HOW WILL THE COPIES BE SUBMITTED:<br />

Electronic<br />

NUMBER OF COPIES SUBMITTED: 1<br />

This shop drawing has been reviewed by the Contractor and certified to be in strict conformance with the Contract Documents as modified by addenda, field orders, and<br />

change orders. Deviations can only be approved by field order or change order. Approval is only for conformance with the design concept of the project and compliance<br />

with the intent of the information given in the Contract Documents. Contractor is responsible for dimensions to be confirmed and correlated at the job site; for information<br />

that pertains solely to the fabrication processes or to techniques of construction; and for the work of all trades.<br />

SUBMITTED BY: Marcus Grace<br />

DATE: 2/28/2012 7:53 PM<br />

REVIEWER COMMENTS<br />

REVIEWER NAME: REVIEWER EMAIL: COMPANY / ORGANIZATION DATE<br />

SENT:<br />

Jeff Hensley<br />

jnh@freese.com<br />

4055 International Plaza<br />

3/1/2012<br />

DATE<br />

COMPLETED:<br />

3/8/2012<br />

REVIEWER<br />

COMMENTS:

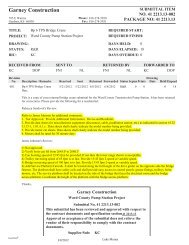

SUBMITTALS<br />

https://projectdox.freese.com/imarkupwg/form.aspformid=6415&wfdirect=&debug=&co...<br />

Page 2 of 2<br />

3/13/2012<br />

1. Approved as Noted. Additional information required. Formally respond to all comment in<br />

writing and provide revised data per review comments.<br />

2. The harmonic analysis shall be done in accordance with Specification <strong>26</strong> <strong>29</strong> <strong>23</strong>.01, paragraph<br />

1.07. The different scenarios required per paragraph 1.07.C. need to be provided at the different<br />

speeds. Provide paragraph clearly listing Utility data used to perform the study. The write-up in<br />

the report shall clearly identify the PCC and give an explanation of the results for each<br />

operating scenario.<br />

3. The harmonic analysis shall clearly identify the PCC at the TPS site as being the 4160V main<br />

switchgear. It currently shows the PCC at the 12.47kV bus.<br />

4. Update harmonic analysis based on comments listed above.<br />

5. Verify <strong>VFD</strong> meets the requirements for true power factor and efficiency as required per the<br />

<strong>VFD</strong> specification.<br />

6. Rearrange the following pushbutton and indicating lights so that they are physically located<br />

horizontally next to each other: Start/Stop, Pump Run/Pump Stop, Valve Open/Closed. Update<br />

drawing to reflect this.<br />

7. One the one-line diagram, a separate external 120V circuit shall be shown going to the motor<br />

space heater. This external 120V circuit shall be shown going through the normally closed SHR<br />

contact. Update all drawings and terminal block layout drawings to reflect this.<br />

8. On one-line diagram add note that 120V for CSH is for temporary storage only.<br />

9. For the three line diagram showing the Multilin 469, the voltage inputs shall be wired to the<br />

Multilin. Update drawing to reflect this.<br />

10. Per <strong>VFD</strong> specification show how the conduits for the control and instrumentation will<br />

physically be terminated to the top of the <strong>VFD</strong>. Show how the cables can be routed in the<br />

spaces provided.<br />

11. Show fuse sizes, CT ratios and HPs on all applicable drawings.<br />

12. In the control schematic for the <strong>VFD</strong>, a <strong>VFD</strong> fault contact shall be wired in series with the<br />

MPR Trip to open the circuit and de-energize CR1. Update drawings to reflect this.<br />

13. The normally open contact CTR2 in the control schematic terminated to terminal 403D<br />

should be a normally closed contact that opens when the timer has timed out.<br />

14. The SCADA Reset normally open contact in the control schematic shall be a normally<br />

closed contact that opens to reset the circuit.<br />

15. Wiring the 4-20mA signals and RTD directly the Card and 469 relay are acceptable.<br />

REVIEWER NAME: REVIEWER EMAIL: COMPANY / ORGANIZATION DATE<br />

SENT:<br />

Rebecca<br />

Sandoval<br />

rs@freese.com<br />

Freese and Nichols, Inc<br />

3/1/2012<br />

DATE<br />

COMPLETED:<br />

3/8/2012<br />

REVIEWER<br />

COMMENTS:<br />

3/8/12<br />

Approved as Noted. Provide Additional Information. Revise and Resubmit. Provide a written<br />

response to each comment on a separate sheet of paper.<br />

See attached for complete comments by R.Sandoval.<br />

Refer to Jeff Hensley for additional comments.<br />

UPLOAD SUPPORTING REVIEW DOCUMENTS<br />

CMD SD-04 MV <strong>VFD</strong> Comments RSandoval 03.08.12.pdf<br />

Remove 3/8/2012 5:07 PM Rebecca Sandoval<br />

DISPLAY ROUTING SLIP<br />

Current Workflow Step: DCS Admin: Debby Greer Workflow Initiator: Marcus Grace<br />

(Click on the Names above to Email User)<br />

FNI Forms v1.04

Rebecca Sandoval Freese and Nichols, Inc.<br />

CMD11<strong>26</strong>9- Contact C4 – Electrical Equipment SD-004 – <strong>Med</strong>ium <strong>Voltage</strong> <strong>VFD</strong>s<br />

3/08/2012<br />

1. Approved as Noted. Provide Additional Information. Revise and Resubmit. Provide a written response to each comment on a<br />

separate sheet of paper.<br />

2. Show the total height of the equipment on the drawings.<br />

3. The <strong>VFD</strong> shall be top entry and exit. Currently this is indicated on the drawings as such but the Load/Controller Data sheet<br />

indicates bottom entry.<br />

4. As indicated in section <strong>26</strong> <strong>29</strong> <strong>23</strong>.01-12, 2.04.D.2 the lights, push buttons, switches, displays, etc. shall be mounted no higher<br />

than 5’-6” AFF which shall include the height of the 4” housekeeping pad. Currently the submittal indicates that these devices<br />

will be located 6’-2” AFF (including the 4” housekeeping pad). If the devices cannot be moved lower then locate the nameplate<br />

for these devices so that it is shown below the device rather than above it.<br />

6. Refer to electrical drawing sheet 16: a) Show the valve switch position table indicated on the FNI TPS <strong>VFD</strong> Pump Control<br />

Schematic. b) See attached mark-ups for additional comments to the control schematic. Changes include removing one of the<br />

duplicate pressure switches that was shown on the FNI schematic. Update all associated drawings to reflect this.<br />

1. Refer to electrical drawing sheet 7, terminals 636 & 636A: The Hand/Off/SCADA label needs to indicate the designation “OOX”<br />

and not “OXO”.<br />

2. Refer to electrical drawing sheet 9: There isn’t any pump bearing RTDs at this site.<br />

3. Drawings shall show cable sizes for the incoming and outgoing sections that the <strong>VFD</strong> can accept as indicated in section <strong>26</strong> <strong>29</strong><br />

<strong>23</strong>.01-4, 1.04.A.2.d.7).<br />

4. Refer to electrical drawing sheet 10: In the bottom left corner there are two lines of text on top of each other.<br />

5. Nameplates shall be black with white letters as indicated in section <strong>26</strong> 13 <strong>23</strong>-12, 2.02.H. Currently the submitted indicates the<br />

nameplates will be white with black letters. Update all associated drawings to reflect this.<br />

Jeff Hensley Comments<br />

1. Approved as Noted. Additional information required. Formally respond to all comment in writing and provide revised data per review<br />

comments.<br />

2. The harmonic analysis shall be done in accordance with Specification <strong>26</strong> <strong>29</strong> <strong>23</strong>.01, paragraph 1.07. The different scenarios required per<br />

paragraph 1.07.C. need to be provided at the different speeds. Provide paragraph clearly listing Utility data used to perform the study. The<br />

write-up in the report shall clearly identify the PCC and give an explanation of the results for each operating scenario.<br />

3. The harmonic analysis shall clearly identify the PCC at the TPS site as being the 4160V main switchgear. It currently shows the PCC at the<br />

12.47kV bus.<br />

4. Update harmonic analysis based on comments listed above.<br />

5. Verify <strong>VFD</strong> meets the requirements for true power factor and efficiency as required per the <strong>VFD</strong> specification.<br />

6. Rearrange the following pushbutton and indicating lights so that they are physically located horizontally next to each other: Start/Stop, Pump<br />

Run/Pump Stop, Valve Open/Closed. Update drawing to reflect this.<br />

7. One the one-line diagram, a separate external 120V circuit shall be shown going to the motor space heater. This external 120V circuit shall be<br />

shown going through the normally closed SHR contact. Update all drawings and terminal block layout drawings to reflect this.<br />

8. On one-line diagram add note that 120V for CSH is for temporary storage only.<br />

9. For the three line diagram showing the Multilin 469, the voltage inputs shall be wired to the Multilin. Update drawing to reflect this.<br />

10. Per <strong>VFD</strong> specification show how the conduits for the control and instrumentation will physically be terminated to the top of the <strong>VFD</strong>. Show how<br />

the cables can be routed in the spaces provided.<br />

11. Show fuse sizes, CT ratios and HPs on all applicable drawings.<br />

12. In the control schematic for the <strong>VFD</strong>, a <strong>VFD</strong> fault contact shall be wired in series with the MPR Trip to open the circuit and de-energize CR1.<br />

Update drawings to reflect this.<br />

13. The normally open contact CTR2 in the control schematic terminated to terminal 403D should be a normally closed contact that opens when the<br />

timer has timed out.<br />

14. The SCADA Reset normally open contact in the control schematic shall be a normally closed contact that opens to reset the circuit.<br />

15. Wiring the 4-20mA signals and RTD directly the Card and 469 relay are acceptable.

135 Dundas Street<br />

Cambridge ON N1R5X1<br />

CANADA<br />

Tel. +1.519.740.4100<br />

Fax +1.519.740.9871<br />

The Reynolds Company<br />

Project Name: Ward County Water Supply<br />

Rockwell Automation Order Number: 7012577<br />

Subject: Response to <strong>VFD</strong> submittal review comments<br />

Date: March 28, 2012<br />

Rebecca Sandoval Comments / RA response<br />

- See current document.<br />

- The total height is shown on individual structural detail pages. See 7012577-001-12D<br />

pg. 2 and on.<br />

- 7012577-001-12D pg. 12, Unit 2A: The "Bottom" load cable exit direction refers to an<br />

internal inter-cabling connection. The drawing has been revised to state as such.<br />

- Height of the pilot devices does not exceed the specified height limit. See revised<br />

7012577-001-12DL.<br />

- Drawing revised. The valve limit switch position table is shown on pg. 2, referenced in<br />

pg. 16.<br />

- Drawing revised.<br />

- Drawing revised.

- See 7012577-001-12D pg. 5 (line cable), and pg. 12 (load cable).<br />

- Drawing revised.<br />

- Drawing revised.<br />

-<br />

Jeff Hensley Comments / RA response<br />

- See current document.<br />

- See Tab 6 revised harmonic analysis. The revised analysis includes three additional<br />

scenarios, one, two and three <strong>VFD</strong>’s running all at 100% speed.<br />

- See Tab 6 revised harmonic analysis<br />

- See Tab 6 revised harmonic analysis<br />

- See Tab 0 - Ward County - Expected <strong>VFD</strong> Efficiency.<br />

- See revised door layout in Tab 1 - 7012577-001-12DL.<br />

- The drawing has been revised to show a separate 120V external supply. However, it is<br />

our standard to omit the SHR contact on the one-line diagram.<br />

- Drawing revised.<br />

- Drawing revised.<br />

- See revised top plate on 7012577-001-12D pg. 4. The new arrangement can<br />

accommodate 8x 2" conduits in total for control cables.<br />

- Drawing revised.

- Drawing revised.<br />

- Drawing revised.<br />

- Drawing revised.<br />

- Acknowledged.<br />

Regards,<br />

Ken Hilderley<br />

Rockwell Automation<br />

Project Manager – MV Drives<br />

Ph: 519 740 4736<br />

Email: khilderley@ra.rockwell.com

Rockwell Automation Transmittal – Approval Drawings/Documentation<br />

Date: March 28, 2012<br />

To:<br />

Attention:<br />

Rockwell Automation<br />

<strong>23</strong>04 Tarpley Road<br />

Carrollton, Texas, USA<br />

75006<br />

972 417 5400<br />

Kevin Nowak<br />

Subject/Project:<br />

Customer:<br />

TRANSMISSION PUMP STATION<br />

WARD COUNTY WATER SUPPLY<br />

Distributor:<br />

THE REYNOLDS COMPANY<br />

Distributor PO#: 1638098-00<br />

RA Order#: 7012577 Item(s): 001 to 020<br />

The conformed submittal has been submitted for information only. The information drawing(s) /<br />

documentation are only submitted when engineering is finalized, at which time manufacturing will<br />

commence. If changes are submitted, the order will then be subject to revision charges and<br />

possible delays in shipment.<br />

1 of 1

RA Order #: 7012577<br />

Submittal Documentation<br />

<strong>Med</strong>ium <strong>Voltage</strong> Equipment<br />

PowerFlex 7000 <strong>Med</strong>ium <strong>Voltage</strong> Drive<br />

Ward County Water Supply<br />

Transmission Pump Station<br />

Description<br />

Table of Contents Page 1 of 3<br />

Rockwell Publication<br />

Transmittal – Ward County<br />

Table of Contents (this document)<br />

Comments and Clarifications for Section <strong>26</strong> <strong>29</strong> <strong>23</strong>.01<br />

<strong>VFD</strong>-Motor Compatibility Letter<br />

Ward County – Expected <strong>VFD</strong> Efficiency<br />

Warranty Letter<br />

Tab 1 Dimensional Drawings<br />

Dimensional Drawing – <strong>VFD</strong>-TPSP1<br />

Dimensional Drawing – <strong>VFD</strong>-TPSP2<br />

Dimensional Drawing – <strong>VFD</strong>-TPSP3<br />

Dimensional Drawing – <strong>VFD</strong>-TPSP4<br />

Plan Layout Drawing<br />

Elevation Drawing<br />

Line Cable Connection Drawing<br />

Tab 2 Electrical Drawings<br />

Electrical Drawing<br />

Tab 3 BOM and Spare Parts<br />

Preliminary Bill of Materials – <strong>VFD</strong> Output Contactor<br />

Preliminary Bill of Materials – <strong>VFD</strong> Input Contactor / FPT<br />

Preliminary Bill of Materials – Variable Frequency Drive<br />

Spare Parts List – Furnished<br />

7012577-001-12D_2<br />

7012577-002-12D_2<br />

7012577-003-12D_2<br />

7012577-004-12D_2<br />

7012577-001-12PL<br />

7012577-001-12DL<br />

7012577-001-12E_2<br />

7012577-017-FBOM<br />

7012577-001-FBOM<br />

7012577-002-FBOM<br />

Publication: 7012577 – March 2012

RA Order #: 7012577<br />

Submittal Documentation<br />

<strong>Med</strong>ium <strong>Voltage</strong> Equipment<br />

PowerFlex 7000 <strong>Med</strong>ium <strong>Voltage</strong> Drive<br />

Ward County Water Supply<br />

Transmission Pump Station<br />

Description<br />

Table of Contents Page 2 of 3<br />

Rockwell Publication<br />

Tab 4 Component Datasheets<br />

469 Motor Protection System 80025-911<br />

Motor Protection Circuit Breakers<br />

140M<br />

IEC Non-Fused Disconnects<br />

194R<br />

Monitoring Safety Relays<br />

440R-G<strong>23</strong>215<br />

Eutatic Alloy Overload Relays 592<br />

DIN Rail Timing Relay<br />

700FS<br />

Heavy-Duty Industrial Relays<br />

700P<br />

30.5mm Push Buttons<br />

800H<br />

Fuse Holders<br />

1492FB<br />

Screw Connection Terminal Blocks<br />

1492J<br />

Supplementary Protector<br />

1492SP<br />

Current Transformer, Donut Type 80022-162<br />

Elapsed Time Meter 80025-413<br />

Curves, MV Fuses<br />

Curves, Potential Transformer Fuses<br />

Curves, TRM Fuses<br />

Curves, Overload Relay<br />

Zero Sequence Current Transformer, 50-0.025 80022-030<br />

Common Mode Choke, Heavy Duty 80022-146<br />

Control Power Transformer, 1kVA 80022-154<br />

Potential Transformer, 600VA 80022-164<br />

Control Power Transformer, 3kVA 80022-197<br />

AC Line Reactor 80022-210<br />

Input Sensing CT, 1000-1 80025-551<br />

Test Switch 80025-597<br />

Capacitor, Motor-Line Filter 800<strong>26</strong>-041<br />

Power Supply, IGDPS 800<strong>26</strong>-044<br />

Hall Effect Current Sensor, 4000-1 800<strong>26</strong>-387<br />

Icar Capacitor 800<strong>26</strong>-511<br />

Publication: 7012577 – March 2012

RA Order #: 7012577<br />

Submittal Documentation<br />

<strong>Med</strong>ium <strong>Voltage</strong> Equipment<br />

PowerFlex 7000 <strong>Med</strong>ium <strong>Voltage</strong> Drive<br />

Ward County Water Supply<br />

Transmission Pump Station<br />

Description<br />

Table of Contents Page 3 of 3<br />

Rockwell Publication<br />

Tab 4 Component Datasheets (continued)<br />

Power Supply, DC-to-DC 800<strong>26</strong>-518<br />

Power Supply, AC-DC (Pioneer 1500W) 800<strong>26</strong>-524<br />

Main Cooling Fan 800<strong>26</strong>-845<br />

400A Moulded Isolator Switch, Bolt-On 80154-544<br />

Vacuum Contactor 80158-691<br />

SGCT, 800A 80173-109<br />

Transient Surge Network 81000-748<br />

Printed Circuit Boards<br />

Tab 5 <strong>VFD</strong> Technical Data<br />

Ward County - Load Capability Curve<br />

PF7000B Heat Loss Information<br />

<strong>VFD</strong>-Motor Protection Parameters<br />

PowerFlex 7000 MV AC Drive Technical Data<br />

GK5.065<br />

7000-TD002B-EN-P<br />

Tab 6 Harmonic Analysis<br />

Ward County – Harmonic Report R2<br />

Tab 7 Factory Testing<br />

General Overview of Rockwell Automation Standard Testing<br />

Typical Test Procedures for MV Products<br />

<strong>Med</strong>ium and Low <strong>Voltage</strong> Test Procedures for PF7000<br />

7000 Family Quality Control Test Listing<br />

Q.C. Inspection Card – PowerFlex 7000<br />

ISO 9001 Certificate<br />

1500-TD220D-EN-E<br />

CSP-2490-198-03<br />

Publication: 7012577 – March 2012

135 Dundas Street<br />

Cambridge Ontario<br />

Canada N1R 5X1<br />

Tel. +1.519.581.7424<br />

Fax. +1.519.740.9871<br />

Ward County Water Supply – Transmission Pump Station<br />

Rockwell Automation Order Number: 7012577<br />

Subject: Comments and Clarifications for Spec Section <strong>26</strong> <strong>29</strong> <strong>23</strong>.01 up to and including Addendum 3<br />

Date: February 19, 2012<br />

__________________________________________________________________________________________________<br />

1.00 GENERAL<br />

1.01 WORK INCLUDED<br />

1.01.A-C Comply.<br />

1.02 QUALITY ASSURANCE<br />

1.02.A-F Comply.<br />

1.02.G As per Meeting Minutes dated January 25, 2012, Rockwell is awaiting FNI to provide the checklist on the<br />

required pump control tests.<br />

1.02.H Comply.<br />

1.03 STANDARDS<br />

1.03.A-G Acknowledged.<br />

1.04 SUBMITTALS<br />

1.04.A.1 Comply.<br />

1.04.A.2.a See current document.<br />

1.04.A.2.b See Tab 1.<br />

1.04.A.2.c See Tab 1.<br />

1.04.A.2.d.1-9 See Tab 1.<br />

1.04.A.2.d.10-13 See Tab 2.<br />

1.04.A.2.e See Tab 3.<br />

1.04.A.2.f-h See Tab 4.<br />

1.04.A.2.i See Tab 3.<br />

1.04.A.2.j-k See Tab 0.<br />

1.04.A.2.l-m See Tab 5.<br />

1.04.A.2.n Not applicable.<br />

1.04.A.2.o See Tab 5.<br />

1.04.A.2.p See Tab 6.<br />

1.04.A.2.q Comply: Field test procedures to be submitted for approval two weeks prior to testing as specified.<br />

1.04.A.2.r Comply.<br />

1.04.A.3-4 Comply.<br />

1.04.A.5 NETA ATS is not within RA's scope of supply.<br />

1.04.A.6-8 Comply.<br />

1.05 DELIVERY, STORAGE AND HANDLING<br />

1.05.A-D Comply.<br />

1.05.E RA standard 150W (120V) cabinet space heaters shall be provided.<br />

Page 1 of 3

1.06 WARRANTY<br />

1.06.A-C Comply.<br />

1.07 HARMONIC ANALYSIS<br />

1.07.A-I Comply.<br />

2.00 PRODUCTS<br />

2.01 GENERAL<br />

2.01.A Comply.<br />

2.01.B The Drive Input Contactor unit consists of a fused non-load-break isolation switch as per 2.02.B.<br />

2.01.C-D Comply.<br />

2.02 ALLEN-BRADLEY <strong>VFD</strong>'S<br />

2.02.A-C Comply.<br />

2.03 Not Applicable<br />

2.04 VARIABLE FREQUENCY DRIVES<br />

2.04.A-C.2 Comply.<br />

2.04.C.3 The <strong>VFD</strong> cooling fans are controlled by internal pressure sensor instead of a thermostat.<br />

2.04.C.4-8 Comply.<br />

2.04.D.1 Comply.<br />

2.04.D.2 Exception: See Elevation Drawing in Tab 1.<br />

2.04.D.3 Comply.<br />

2.04.E.1 The <strong>VFD</strong> lineup has total length of 207.54", which includes the input/output contactors and the fan power<br />

transformer cabinet. See Tab 1 – 7012577-001-12D.<br />

2.04.E.2 The RA standard CT's at 300:5 have a class C20 accuracy. C200 refers to CT's with much higher primary<br />

current ratings, which is not applicable in this project.<br />

2.04.E.3-5 Comply.<br />

2.04.E.6 RA standard Crompton Elapsed Time Meter shall be provided. See 80025-413 in Tab 4.<br />

2.04.E.7-10 Comply.<br />

2.04.E.11 RA standard 1492-J4 terminal blocks shall be provided. See 1494J in Tab 4.<br />

2.04.E.12 Comply.<br />

2.04.E.13 The <strong>VFD</strong> cooling fans are controlled by internal pressure sensor instead of a thermostat.<br />

2.04.E.14-17 Comply.<br />

2.04.F Comply.<br />

2.04.G.1.a-h Comply.<br />

2.04.G.1.i 3 CT’s and 1 GFCT of RA standard shall be provided.<br />

2.04.G.1.j Comply.<br />

2.04.G.1.k Digital I/O's will be wired to terminal blocks. It is advised that the analog signals be wired directly onto<br />

the respective device terminals (i.e. speed reference, speed feedback, and RTD's).<br />

2.04.H-J Comply.<br />

3.00 EXECUTION<br />

3.01 GENERAL<br />

3.01.A-B Comply.<br />

3.02 INSTALLATION AND START-UP<br />

3.02.A-E Comply.<br />

3.03 TRAINING<br />

3.03.A-D Comply.<br />

3.03.E Rockwell shall submit the training outline 4 weeks prior to the training at a minimum, as specified.<br />

3.03.F-G Comply.<br />

Page 2 of 3

3.04 FIELD QUALITY CONTROL<br />

3.04.A-K Comply.<br />

3.05 SPARE PARTS<br />

3.05.A Comply: See Tab 3.<br />

3.06 CLEAN AND ADJUST<br />

3.06.- Comply.<br />

Please feel free to contact me directly regarding any technical issue or concern.<br />

Sincerely,<br />

Richard Yang, P.Eng<br />

Application Engineer, MV Drives<br />

Rockwell Automation Canada<br />

Tel: +1.519.740.4100 ext. 2496<br />

Email: rdyang@ra.rockwell.com<br />

Page 3 of 3

135 Dundas Street<br />

Cambridge Ontario<br />

Canada N1R 5X1<br />

Tel. +1.519.581.7424<br />

Fax. +1.519.740.9871<br />

Ward County –Transmission Pump Station<br />

Rockwell Automation Order Number: 7012577<br />

Subject: <strong>VFD</strong>-Motor Compatibility Certification<br />

Date: February 19, 2012<br />

__________________________________________________________________________________________<br />

Rockwell Automation certifies that the PowerFlex 7000, B-Frame, 215A <strong>VFD</strong>’s to be supplied for the Ward<br />

County Transmission Pump Station will operate the Teco-Westinghouse 4000V, 1500HP, 197A, 1186RPM<br />

motors, as per the motor data sheet dated January 30, 2012 (S.O. 0A63AA).<br />

Regards,<br />

Richard Yang, P.Eng<br />

Application Engineer, MV Drives<br />

Rockwell Automation Canada<br />

Tel: +1.519.740.4100 ext. 2496<br />

Email: rdyang@ra.rockwell.com

Ward County – Expected <strong>VFD</strong> Efficiency at Varied Speed (1500HP <strong>VFD</strong>)<br />

SPEED (%) Spec <strong>VFD</strong> Efficiency (%) Power Factor<br />

100 97.0 0.97<br />

80 96.0 0.961

135 Dundas Street<br />

Cambridge Ontario<br />

Canada N1R 5X1<br />

Tel. +1.519.581.7424<br />

Fax. +1.519.740.9871<br />

Ward County – Transmission Pump Station<br />

Rockwell Automation Order Number: 7012577<br />

Subject: <strong>VFD</strong> Warranty<br />

Date: February 19, 2012<br />

Rockwell Automation is providing the following warranty for <strong>VFD</strong>-TPSP1, <strong>VFD</strong>-TPSP2, <strong>VFD</strong>-<br />

TPSP3, and <strong>VFD</strong>-TPSP4 to be installed at the Ward County Transmission Pump Station:<br />

Parts and Labor Warranty: (24) months following the installation, adjusting and<br />

acceptance testing, and the start of actual operation of the equipment, or (30)<br />

months from shipment, whichever occurs first.<br />

Richard Yang, P.Eng<br />

Rockwell Automation<br />

Application Engineer – MV Drives<br />

Ph: 519-740-4100 ext. 2496<br />

Email: rdyang@ra.rockwell.com<br />

1 of 1

Line Cable Connection<br />

Drawing – <strong>VFD</strong>‐TPSP1/2/3/4<br />

Unit 2A/2B, See 7012577‐001‐12D

Ward County Water Supply<br />

Transmission Pump Station<br />

Preliminary Bill of Materials<br />

<strong>VFD</strong> Output Contactor<br />

Unit Location: 1A<br />

Series Number: 7012577-017/018/019/020-12<br />

ED Number: 7012577-001-12E<br />

DD Number: 7012577-001/002/003/004-12D<br />

Catalog No: 1599-ADE<br />

Part No.<br />

Part Description<br />

Qty<br />

80154-736-52 18" MV DOOR SPEC PAINT T1 2<br />

80253-066-53 GASKETING FOR 18" DOORS 1<br />

80013-111-01 CABLE SUPPORT 2HI36 1<br />

80144-887-53 MV DOOR CLIP ASSY BOT DOOR 1<br />

80158-691-52 400A EH 5KV SER E VAC CONT 1<br />

80183-242-51 400A CONT'R MTG ASSY 18" CAB 1<br />

80187-0<strong>26</strong>-02 CABLE BRACE MOUNTING BRACKET 1<br />

80253-006-52 18" CAB. ASSY. SPEC. PNT. 1<br />

80255-003 ASSY INSTRU. 18" INC. SER. B 1<br />

LABKITREQD FA LABEL KIT REQUIRED "FA" 1<br />

80253-174-51 LABEL KIT,5KV "FA" - ENGLISH 1<br />

7012577-017-FBOM 1 of 1

Ward County Water Supply<br />

Transmission Pump Station<br />

Preliminary Bill of Materials<br />

<strong>VFD</strong> Input Contactor<br />

Unit Location: 2A<br />

Series Number: 7012577-001/011/013/015-12<br />

ED Number: 7012577-001-12E<br />

DD Number: 7012577-001/002/003/004-12D<br />

Catalog No: 1512BD-ADE-6B-7F-4010-5010D-5051<br />

Part No.<br />

Part Description<br />

80022-154-03 CPT,1KVA,4200:115/<strong>23</strong>0,50/60HZ 1<br />

80253-055-53 (1)CPT UNDER 2KVA TOP CELL 2H 1<br />

80253-324-51 1-CPT 110/120V ASSY COMP'NTS 1<br />

80006-316-01 DANGER LABEL LIVE CIRC. ENG. 1<br />

80153-591-58 MV DOOR ASSY 1<br />

80154-956-62 2H LV DOOR BOT&TOP 4PD SPEC PT 1<br />

80253-066-55 GASKETING FOR 36" 2HI DOORS 1<br />

80253-161-51 LABEL KIT, 5KV "DR" - ENGLISH 1<br />

H-17350 NAMEPLATE WHITE BLANK 1<br />

40<strong>26</strong>6-515-01 20A CARTRIDGE ASSY. 700-CPM 4<br />

80010-900-76 STAMPING INSTRUCTNS,FUSE LABEL 1<br />

80025-<strong>23</strong>9-01 1E 4800V 5" FUSE A480T1E 2<br />

80025-<strong>29</strong>6-10 FUSE:BOLT-ON-A051B1DARO-19R 3<br />

80153-479-02 VACUUM CONTACTOR MTG. PLATE 1<br />

80153-646-53 THERMOSTAT & HEATER ASSY. 1<br />

80154-132-57 TRANSFORMER AND BRACE ASSY. 1<br />

80154-544-51 400A MOULDED ISOLATOR SW B/O 1<br />

80157-982-51 HANDLE MODULE ASSEMBLY 1<br />

80157-983-53 KEY INTERLOCK ASSY."F" (OFF) 1<br />

80158-002-68 R.H. SIDEPLATE WELD ASSY 1<br />

80158-691-52 400A EH 5KV SER E VAC CONT 1<br />

80158-975-57 DONUT CT 300:5 RATIO TOP 1<br />

80253-004-60 CABINET ASSY (2HI) ( 2 UNIT ) 1<br />

80253-015-51 TRAILER FB BOLT TYPE FUSES 1<br />

80253-020-52 DONUT CT PWR WIRE 4/0 TOP EXIT 1<br />

80253-100-54 B/ASSY 1592BF T/E 1512B T/E 2U 1<br />

80253-141-59 LINE & LOAD LUGS ASSY (BAGGED 2<br />

80255-002 CAB ASSY INSTRUCTIONS 1512-B 1<br />

LABKITREQD FA LABEL KIT REQUIRED "FA" 1<br />

80253-160-51 LABEL KIT, 5KV "FA" - ENGLISH 1<br />

80253-162-51 LABEL KIT, 5KV "PL" - ENGLISH 1<br />

1492-FB1M30 MIDGET FUSE HLDER,1 1/2"X13/32 1<br />

1492-J4 IEC ONE-CIRCUIT FEED-THROUGH B 20<br />

592-BOV16 OVERLOAD RELAY SIZE 1 1<br />

700-N24 SURGE SUPPRESSOR - 150V MAX 1<br />

700-PK400A1 CONTROL RELAY 1<br />

80006-047-10 2A 250V FUSE LABEL 2<br />

80006-047-33 8A 250V FUSE LABEL 1<br />

80018-5<strong>29</strong>-56 1512B PC WIRE HARNESS(TEW) 1<br />

80098-968-09 BUL.1503 INTVAC+ 400A E/H TDUV 1<br />

80158-824-52 SC LV TEST SWT ENG. 1<br />

80178-370-52 CONTACTOR CTRL MOD INTELLIVAC 1<br />

7012577-001-FBOM 1 of 3<br />

Qty

80253-058-51 LV ASSEMBLY 2HI 1<br />

80255-062 LV PANEL ASSY INSTR 1512-B 1<br />

F-22013 1492 TERMINAL BLOCK BARRIER 2<br />

H-17731 TB N/P FOR LIVE TERMINALS 2<br />

LABKITREQD PL LABEL KIT REQUIRED "PL" 1<br />

W41 HEATER ELEMENT 3<br />

X-251083 2 AMP 250V MINI FUSE TRM2 2<br />

X-251094 8 AMP 250V MINI FUSE TRM 8 1<br />

7012577-001-FBOM 2 of 3

Ward County Water Supply<br />

Transmission Pump Station<br />

Preliminary Bill of Materials<br />

FPT Load Break Switch<br />

Unit Location: 2B<br />

Series Number: 7012577-001/011/013/015-12<br />

ED Number: 7012577-001-12E<br />

DD Number: 7012577-001/002/003/004-12D<br />

Catalog No: 1592BF-TDED-5010D<br />

Part No.<br />

Part Description<br />

Qty<br />

80153-591-58 MV DOOR ASSY 1<br />

80154-956-62 2H LV DOOR BOT&TOP 4PD SPEC PT 1<br />

H-17350 NAMEPLATE WHITE BLANK 1<br />

80010-901-93 15A GOULD FUSE LABEL INSTR 1<br />

80025-200-18 FUSE/CLIP-ON-A055F1DORO-15E 3<br />

80025-6<strong>29</strong>-01 LB SWITCH, POWERCON 502-900 1<br />

80154-132-57 TRANSFORMER AND BRACE ASSY. 1<br />

80157-982-53 HANDLE MODULE ASSY.(LD BRK SW) 1<br />

80158-221-69 INSULATOR & LOAD TRML. ASSY 1<br />

80253-099-51 400ALB CHAIN C/O FUSECLIP ASSY 1<br />

80253-101-56 36" CABINET STRIP HEATER ASSY 1<br />

80253-220-55 CABLE, #2 8KV TOP EXIT CLIP-ON 1<br />

FPT Fan Power Transformer: 8kVA 1<br />

80253-224-51 LV SWINGOUT PANEL ASSY. 1<br />

80255-060 LV PANEL ASSEMBLY INSTRUCTIONS 1<br />

7012577-001-FBOM 3 of 3

Ward County Water Supply<br />

Transmission Pump Station<br />

Preliminary Bill of Materials<br />

Variable Frequency Drive<br />

Unit Location: 3A-6A<br />

Series Number: 7012577-002/012/014/016-12<br />

ED Number: 7012577-001-12E<br />

DD Number: 7012577-001/002/003/004-12D<br />

Catalog No: 7000-A215DE-RPDTD-1EDSTP-1STP-1STR-13COMME-14RF-14TS1-<br />

14TS2-14TS3-14TS4-14TS5-17-85T-760A-804-5010E-5025D<br />

Part No.<br />

Part Description<br />

Qty<br />

81005-122-76 DOOR KIT B FRAME 1<br />

H-17350 NAMEPLATE WHITE BLANK 1<br />

80022-030-02 50/0.025 ZERO SEQ CT 301838 1<br />

80022-210-12 AC L.R.,3300V/50,4160V/60,ND 1<br />

800<strong>26</strong>-511-<strong>23</strong> ICAR MF/LINE CAP,4160V,300KVAR 1<br />

800<strong>26</strong>-511-24 ICAR MF/LINE CAP,4160V,400KVAR 1<br />

80050-163 ASSY INSTR NEUTRAL RES 7000B 2<br />

81000-041-51 FA PARTS LINE REACTOR CAB 1<br />

81005-063-63 LOOSE PARTS,B FRM 2400V-PVM 1<br />

81005-120-64 BCKPLT,W/W & CONDUIT COVER KIT 1<br />

81007-561-58 900MM CAP MOUNTING FA KITS 1<br />

81007-996-51 DOOR INTERLOCK 1<br />

81011-046-10 CAP RETAINING BRACKET 2<br />

81011-046-18 CAP RETAINING BRACKET (MULT) 2<br />

KEYINTLREQD KEY INTERLOCK 1<br />

LABKITREQD FA LABEL KIT REQUIRED "FA" 1<br />

81000-018-51 DRIVE LABEL KIT - ENGLISH ONLY 1<br />

W-662 SILICONE 108 RTV 82.8 ML 1<br />

81002-<strong>23</strong>4-52 NEUTRAL RESISTOR ASSY,7000B 1<br />

81001-373-51 FAN MOUNTING ASSEMBLY 1<br />

81007-766-52 FAN EXHAUST HOOD ASSY 1<br />

80004-170-01 13.00 X 10.00 ENVELOPE 1<br />

800<strong>26</strong>-191-05 TX-30 TORX DRIVER #3F1606J9 1<br />

800<strong>26</strong>-191-06 HEX KEY HANDLE #1F12<strong>23</strong>T1 1<br />

81005-069-80 SPARE PARTS KIT 1<br />

81005-074-58 TEST KIT - PWM CC 1<br />

80014-444-01 GROUND LUG 250MCM 10 MM 3<br />

80018-036-01 LUGGED WIRE,12AWG,135" LONG 6<br />

81001-646-51 POWERCAGE LABEL KIT - ENGLISH 1<br />

81007-781-52 CABINET ASSY 900MM LR 1<br />

81007-939-64 TOP PLATE WELDMENTS 1<br />

40011-079-01 BLANK LEGEND PLATE 10<br />

40011-080-02 LEGEND PLATE "START" 1<br />

40011-081-03 LEGEND PLATE "STOP" 1<br />

40274-386-01 FINGER SAFE MULTI-TERM. COVER 10<br />

40274-387-01 FINGER SAFE TRANS. TERM. COVER 8<br />

80011-184-02 LEGEND PLATE-SPEED 1<br />

80011-205-04 LEGEND PLT-EMERG STOP PTS PTR 1<br />

80025-413-01 ELAPSED TIME METER,3.5,60HZ 1<br />

80025-975-01 INSUL TERM. COVER FOR 1/4 STUD 2<br />

7012577-002-FBOM 1 of 3

800<strong>26</strong>-658-35 MULTILIN SR469-P5-HI-A20-T-H 1<br />

800H-AR2A PUSH BUTTON FLUSH HEAD 1<br />

800H-JR2B SELECTOR SWITCH UNIT 1<br />

800H-PRH16W WHITE LED PILOT LIGHT 1<br />

800H-PRTH16A AMBER PUSH-TO-TEST PILOT LIGHT 1<br />

800H-PRTH16G GREEN PUSH-TO-TEST PILOT LIGHT 2<br />

800H-PRTH16R RED PUSH TO TEST PILOT LIGHT 1<br />

800H-PRTH16W WHITE PUSH TO TEST PILOT LIGHT 1<br />

800T-N1B HOLE PLUG KIT 1<br />

80253-361-51 800H PUSHBUTTONS 1<br />

80253-361-52 800H PUSHBUTTONS 1<br />

80253-361-54 800H PUSHBUTTONS 1<br />

80253-363-51 SPEED POTENTIOMETER ASSEMBLY 1<br />

81001-449-05 PF7000 PV TERMINAL W/PROG,ENGL 1<br />

81004-183-10 LV DOOR ADAPTER PLATE 1<br />

F-21788 GASKET FOR FIESTA AMMETER 1<br />

H-30861 MASTER NAMEPLATE WHITE BLANK 1<br />

80022-030-01 ZERO SEQ CT 5.5" WINDOW 301837 1<br />

80022-162-13 CT 300:5 C/W 2.00" WINDOW 3<br />

800<strong>26</strong>-041-75 MF/LINE CAP,4160V,500KVAR 1<br />

80255-086 FASTENER CONFIGS FOR DC LINK 1<br />

81000-014-51 FA PARTS FOR 900MM INPUT CAB 1<br />

81000-094-84 CABLE KIT 215A 1<br />

81001-050-51 CAPACITOR MOUNTING ASSY 1<br />

81007-593-16 CAPACITOR RETAINING BRACKET 2<br />

81001-484-54 TSN/ARRESTER WIRE HARNESS 1<br />

80018-317-51 18P VSB HARN,PWM,<strong>23</strong>00/4160V 1<br />

81000-915-51 TERMINAL ASSY.18 PULSE 1200MM 1<br />

81000-915-53 TERMINAL ASY 1200MMCAP,INC CAB 1<br />

81001-303-53 THERMOSTAT/STRIP HEATER ASSY 1<br />

81001-325-51 RECTIFIER BUS ASSY 900MM INPUT 1<br />

81001-331-51 CONV-LR 1000:1 CT & INC PARTS 1<br />

81001-608-51 LEM/BUS ASSY,900MM,ES1000,8KV 1<br />

81007-465-51 VOLT SENSE BD,SERA,CONF COATED 2<br />

22401-603-01 INSULATOR 10<br />

800<strong>26</strong>-693-02 6KV, SURGE ARRESTER URT 3<br />

81002-756-02 GROUND BUS FOR ARRESTER 1<br />

81002-891-01 SURGE ARRESTER BARRIER B-FRAME 1<br />

81007-317-52 900MM INC/CAP 6P CAB UP COMP 1<br />

100-C09D200 9 AMP CONTACTOR 1<br />

100-FSC280 SURGE SUPPRESSOR 1<br />

1492-SP1C020 SUPPLEMENTARY PROTECTOR 1<br />

1492-SP1C060 SUPPLEMENTARY PROTECTOR 1<br />

1492-SP1C070 SUPPLEMENTARY PROTECTOR MINIA 2<br />

20-COMM-E ETHERNET/IP TO DPI COMM. CARD 1<br />

440R-G<strong>23</strong>215 SAFETY RELAY--MSR142RTP 1<br />

700-FSM4UU<strong>23</strong> TIMING RELAY 1<br />

700-N24 SURGE SUPPRESSOR - 150V MAX 2<br />

700-PK400A1 CONTROL RELAY 10<br />

700-PK600A1 CONTROL RELAY 1<br />

80025-334-01 RECEPTACLE STEGO 03504.0-00 1<br />

80025-644-01 CIM SIGNAL CONDITIONER(ITC-62) 3<br />

800<strong>26</strong>-600-01 RES,5-OHM,3W,FORMED+SHK TUBE 2<br />

800<strong>26</strong>-600-03 RES,50-OHM,3W,FORMED+SHK TUBE 3<br />

81002-174-52 FORGE LV TUB ASSY CONFCOAT 1<br />

81002-521-57 B-FRAME LV PANEL ASSY 6P/PWM 1<br />

81002-744-61 OPTIC BOARD KIT-3300/4160V,PWM 1<br />

81002-572-51 4 DEV PWRCAGE ASSY 4<br />

81002-572-53 4 DEV PWRCAGE ASSY 2<br />

81007-996-51 DOOR INTERLOCK 1<br />

81001-436-54 50VDC HARNESS 3300/4160V RPLR 1<br />

81000-812-02 CONVERTER BUS LINK 6<br />

81000-864-56 PWR SUPPLY ASSY <strong>23</strong>00V-6600V 4<br />

81000-865-52 BUS SUPPT & AIR FLOW BARR.CONV 1<br />

81001-549-51 4 DEV.1000MM BUS MODULE 2<br />

7012577-002-FBOM 2 of 3

81001-614-54 50V HARNES KIT 3300/4160V-4DEV 1<br />

81007-496-57 4 DEVICE PWRCAGE W/MID EFF ASY 2<br />

81007-496-58 4 DEVICE PWRCAGE W/MID EFF ASY 1<br />

81007-496-63 4 DEVICE PWRCAGE W/MID EFF ASY 2<br />

81007-496-64 4 DEVICE PWRCAGE W/MID EFF ASY 1<br />

81000-997-51 FLEXIBLE POWER CONN ASY 1000MM 6<br />

81004-577-01 WIRE TIE MTG CHANNEL-SGCT PS 4<br />

81007-321-61 1000MM CONV CAB 6P UP COMP 1<br />

80022-197-12 CPT,480:120V 60HZ 3KVA 1<br />

81002-665-02 MV CPT COVER IN DC LINK CAB SP 1<br />

80022-146-12 COM MODE CHOKE,HDUTY,3300/4160 1<br />

81000-045-53 CMC FA PARTS, 1100MM WIDE 1<br />

81000-046-51 FA PARTS FOR COM MODE CHOKE 1<br />

81001-415-61 HECS ASSY ES1000,8KV JUMPR,CMC 1<br />

81007-680-72 WIRED FAN, 3.7KW,460V,60HZ,50C 1<br />

81007-680-97 WIRED FAN,3.7KW,460V,60HZ,REDU 1<br />

81000-071-57 MF560 FAN MTG UPENDER PARTS 1<br />

81002-246-60 REDUND. FAN ASSY FOR 900MM CAB 1<br />

81007-328-52 1100MM CMC CAB UP COMP 1<br />

1492-SP2D100 SUPPLEMENTARY PROTECTOR MINIA 1<br />

81002-504-53 PANEL ASSY FOR DC LINK/CMC CAB 1<br />

81005-057-74 FAN CTRL 110/120V,10A MAX 2<br />

81005-075-61 POWER SUPPLY COMPONENT KIT 1<br />

81007-2<strong>23</strong>-61 B-FRAME 2FAN/1PS WIRE HARNESS 1<br />

81007-224 WIRE HARNESS INSTRUCTIONS 1<br />

469P5HIA20T MULTILIN 469 1<br />

7012577-002-FBOM 3 of 3

7012577 - Ward County Water Supply Spare Parts Furnished as per Spec <strong>26</strong> <strong>29</strong> <strong>23</strong>.01<br />

Part Number Description Total Qty<br />

Spare Parts Furnished as per Spec <strong>26</strong> <strong>29</strong> <strong>23</strong>.01, 3.05<br />

1. Six of each type of power and control fuse rated 600V or less<br />

80145-871-52-R (2)1A ATM FUSE ASSY 3<br />

80174-902-14-R 6.3A 250V INTERNAL FUSE 6<br />

X-251083-R 2 AMP 250V MINI FUSE TRM2 6<br />

X-251094-R 8 AMP 250V MINI FUSE TRM 8 6<br />

2. Six of each type of fuse rated greater than 600V<br />

25172-551-02-R 0.5E 4800V GOULD 5" FUSE 6<br />

25172-551-04-R FUSE 4E 4800V GOULD 5 INCH 6<br />

80025-200-17-R PKG-FUSE 10E-5500V-CLIP ON 6<br />

80025-<strong>23</strong>9-01-R FUSE,1E 4800V GOULD 5" 6<br />

80025-<strong>29</strong>6-10-R FUSE: BOLT-ON A051B1DARO-19R 6<br />

3. Two of each type of panel lamp<br />

800T-N318A 6V FULL VOLTAGE LED AMBER 2<br />

800T-N318G 6V FULL VOLTAGE LED GREEN 2<br />

800T-N318R 6V FULL VOLTAGE LED RED 2<br />

800T-N318W 6V FULL VOLTAGE LED WHITE 2<br />

4. One of each type of printed circuit board, including diagnostic systems<br />

346567-Q01-R PKG BATTERY,3V,300MA,<strong>23</strong>MM-COIN 1<br />

800<strong>26</strong>-044-06-R PWR SUPPLY - IGCT, ALL VOLTAGE 1<br />

80190-540-05-R PKGD CUSTR TFB,CONFORMAL COAT 1<br />

80190-560-01-R PKGD CUSTOMER ACB BOARD ASSY 1<br />

80190-600-01-R PKGD CUSTOMER OIBB BOARD ASSY 1<br />

81007-465-51-R VOLTAGE SENSING BOARD (SER A.) 1<br />

5. One spare EPROM chip for each <strong>VFD</strong><br />

80190-580-01-R PKGD CUSTOMER DPM BOARD ASSY 1<br />

6. One microprocessor-based interface display and monitoring panel, and keypad<br />

81001-449-05-R POWERFLEX TERMINAL W/PROGRAM 1<br />

7. One spare relay and timer of each type<br />

700-FSM4UU<strong>23</strong> TIMING RELAY 1<br />

700-PK400A1 CONTROL RELAY 1<br />

700-PK600A1 CONTROL RELAY 1<br />

8. One of each fan or blower installed<br />

800<strong>26</strong>-845-03-R FAN/MOTOR,460V,60HZ,5HP,50C 1<br />

9. One PWM power cell or power module for each <strong>VFD</strong><br />

81001-450-52-R PKGD (2) SGCT MATCHED SET 800A 1<br />

10. All spare parts and lubricants required for the first year preventive maintenance<br />

X-336609 TOUCH UP PAINT GREY ASA 61 1

469<br />

Motor Protection System<br />

Complete integrated protection<br />

and management of medium<br />

and large motors<br />

Motor Protection<br />

Key Benefits<br />

• Comprehensive motor protection plus voltage dependant<br />

overload curves, torque metering and protection, broken<br />

rotor bar protection<br />

• Most advanced thermal model - Including multiple RTD<br />

inputs for stator thermal protection<br />

• Minimize replacement time - Draw-out construction<br />

• Complete asset monitoring - Temperature, Analog I/O, full<br />

metering including demand & energy<br />

• Improve uptime of auxiliary equipment - Through I/O<br />

monitoring<br />

Applications<br />

• Reduce troubleshooting time and maintenance costs -<br />

Event reports, waveform capture, data logger<br />

• Built in simulation functions simplify testing and<br />

commissioning<br />

• Cost Effective Access to information - Through standard<br />

RS<strong>23</strong>2 & RS485 serial ports, and optional Ethernet and<br />

DeviceNet Ports<br />

• Field upgradable firmware and settings<br />

• Optional Conformal coating for exposure to chemically<br />

corrosive or humid environments<br />

• Protection and Management of three phase medium and large horsepower motors and<br />

driven equipment, including high inertia, two speed and reduced-voltage start motors.<br />

Features<br />

Protection and Control<br />

• Thermal model biased with RTD and negative<br />

sequence current feedback<br />

• Start supervision and inhibit<br />

• Mechanical jam<br />

• <strong>Voltage</strong> compensated acceleration<br />

• Undervoltage, overvoltage<br />

• Underfrequency<br />

• Stator differential protection<br />

• Thermal overload<br />

• Overtemperature protection<br />

• Phase and ground overcurrent<br />

• Current unbalance<br />

• Power elements<br />

• Torque protection<br />

• Dual overload curves for 2 speed motors<br />

• Reduced voltage starting control<br />

Communications<br />

• Multiple Ports - 10baseT Ethernet, RS485, RS<strong>23</strong>2, RS422,<br />

DeviceNet<br />

• Multiple Protocols - Modbus RTU, Modbus TCP/IP, DeviceNet<br />

Monitoring and Metering<br />

• A, V, W, var, VA, PF, Hz, Wh, varh, demand<br />

• Torque, temperature (12 RTDs)<br />

• Event recorder<br />

• Oscillography & Data Logger (trending)<br />

• Statistical information & learned motor data<br />

EnerVista TM Software<br />

• State of the art software for configuration and<br />

commissioning GE Multilin products<br />

• Document and software archiving toolset to ensure<br />

reference material and device utilities are up-to-date<br />

• EnerVista TM Integrator providing easy integration of data<br />

in the 469 into new or existing monitoring and control<br />

systems<br />

g<br />

Digital Energy<br />

Multilin<br />

397

469 Motor Protection System<br />

Motor Protection<br />

Protection and Control<br />

The 469 is a digital motor protection<br />

system designed to protect and manage<br />

medium and large motors and driven<br />

equipment. It contains a full range<br />

of selectively enabled, self contained<br />

protection and control elements as<br />

detailed in the Functional Block Diagram<br />

and Features table.<br />

Motor Thermal Model<br />

The primary protective function of the<br />

469 is the thermal model with six key<br />

elements:<br />

• Overload Curves<br />

• Unbalance Biasing<br />

• Hot/Cold Safe Stall Ratio<br />

• Motor Cooling Time Constants<br />

• Start Inhibit and Emergency Restart<br />

• RTD Biasing<br />

Overload Curves<br />

The curves can take one of three formats:<br />

standard, custom, or voltage dependent.<br />

For all curve styles, the 469 retains thermal<br />

memory in a thermal capacity used<br />

register which is updated every 0.1 second.<br />

The overload pickup determines where the<br />

running overload curve begins.<br />

The 469 standard overload curves are of<br />

standard shape with a multiplier value of<br />

1 to 15.<br />

The voltage dependent overload curves<br />

are used in high inertia load applications,<br />

where motor acceleration time can<br />

actually exceed the safe stall time and<br />

motor thermal limits. During motor<br />

acceleration, the programmed thermal<br />

overload curve is dynamically adjusted<br />

with reference to the system voltage level.<br />

The selection of the overload curve type<br />

and the shape is based on motor thermal<br />

limit curves provided by motor vendor.<br />

TRIP TIME (seconds)<br />

10000<br />

10,000<br />

1000<br />

1,000<br />

100<br />

10<br />

1<br />

TYPICAL CUSTOM CURVE<br />

6500 HP, 13800 VOLT INDUCED DRAFT FAN MOTOR<br />

1 PROGRAMMED 469 CUSTOM CURVE<br />

CURVE<br />

15<br />

12<br />

9<br />

7<br />

4<br />

3<br />

2<br />

0.1<br />

1<br />

10<br />

Full Load<br />

Setpoint PHASE CURRENT<br />

(multiples of full load)<br />

819765A8.cdr<br />

Fifteen standard overload curves.<br />

2 RUNNING SAFETIME (STATOR LIMIT)<br />

3 ACCELERATION SAFETIME (ROTOR LIMIT)<br />

4 MOTOR CURRENT @ 100% VOLTAGE<br />

5 MOTOR CURRENT @ 80% VOLTAGE<br />

1<br />

Functional Block Diagram<br />

1<br />

52<br />

50 50G<br />

TIME TO TRIP IN SECONDS<br />

100<br />

10<br />

2<br />

3<br />

BUS<br />

4<br />

2<br />

27<br />

59 47 81<br />

R2<br />

AUXILIARY<br />

1.0<br />

5<br />

3<br />

3<br />

AMBIENT AIR<br />

RTD<br />

MOTOR<br />

STATOR RTDs<br />

BEARING RTDs<br />

LOAD<br />

14<br />

TACHOMETER<br />

DCMA<br />

R1<br />

TRIP<br />

50<br />

50G<br />

87<br />

49<br />

38<br />

METERING<br />

V,A,W,Var,VA,PF,Hz<br />

55<br />

51 49 37 66 46<br />

51G<br />

78<br />

4 ANALOG INPUTS<br />

R3<br />

AUXILIARY<br />

R4<br />

ALARM<br />

R5<br />

BLOCK<br />

START<br />

R6<br />

SERVICE<br />

74<br />

86<br />

4 ISOLATED<br />

ANALOG<br />

OUTPUTS<br />

469<br />

Motor Management System<br />

14<br />

START<br />

RS<strong>23</strong>2<br />

RS485<br />

RS485<br />

Ethernet<br />

0.1<br />

0.5 1.0 10 100 1000<br />

MULTIPLE OF FULL LOAD CURRENT SETPOINT<br />

Typical custom overload curve.<br />

806803A5.cdr<br />

Device<br />

Number<br />

Function<br />

14 Speed switch<br />

19/48<br />

Reduced voltage start and<br />

incomplete sequence<br />

27/59 Undervoltage/Overvoltage<br />

Reverse power<br />

32<br />

Mechanical Jam<br />

Acceleration time<br />

Over Torque<br />

37 Undercurrent/Underpower<br />

38 Bearing RTD<br />

46 Current Unbalance<br />

47 Phase Reversal<br />

49 Stator RTD<br />

50 Short circuit backup<br />

50G/51G Ground overcurrent backup<br />

51 Overload<br />

55 Power factor<br />

66<br />

Starts/hour and time between<br />

starts<br />

81 Frequency<br />

86 Overload lockout<br />

87 Differential<br />

806807A7.cdr<br />

398<br />

www.GEDigitalEnergy.com

469 Motor Protection System<br />

Unbalance (Negative Sequence<br />

Current) Biasing<br />

Negative sequence current, which causes<br />

rotor heating, is not accounted for in<br />

the thermal limit curves supplied by the<br />

motor manufacturer. The 469 measures<br />

unbalance as the ratio of negative to<br />

positive sequence current. The thermal<br />

model is biased to reflect the additional<br />

heating. Motor derating due to current<br />

unbalance can be selected via the setpoint<br />

unbalance bias k factor. Unbalance<br />

voltage causes approximately 6 times<br />

higher level of current unbalance (1% of<br />

voltage unbalance equal to 6% of current<br />

unbalance). Note that the k=8 curve is<br />

almost identical to the NEMA derating<br />

curve.<br />

Hot/Cold Safe Stall Ratio<br />

The Hot/Cold Safe Stall time ratio defines<br />

the steady state level of thermal capacity<br />

used (TCU) by the motor. This level<br />

corresponds to normal operating<br />

temperature of the fully loaded motor and<br />

will be adjusted proportionally if motor<br />

load is lower then rated.<br />

The Hot/Cold Safe Stall ratio is used by the<br />

relay to determine the lower limit of the<br />

running cool down curve, and also defines<br />

the thermal capacity level of the central<br />

point in RTD Biasing curve.<br />

Derating Factor<br />

1.00<br />

0.95<br />

k=2<br />

0.90<br />

k=4<br />

0.85<br />

k=6<br />

0.80<br />

k=8<br />

0.75<br />

k= 10<br />

0.70<br />

0 1 2 3 4 5<br />

Percent <strong>Voltage</strong> Unbalance<br />

Motor derating factor due to unbalanced voltage<br />

Motor Cooling Time Constants<br />

When the 469 detects that the motor is<br />

running at a load lower then overload<br />

pickup setpoint, or the motor is stopped,<br />

it will start reducing the stored TCU<br />

value, simulating actual motor cool down<br />

process. TCU decays exponentially at a<br />

rate dictated by Cooling Time Constants<br />

setpoints. Normally the cooling down<br />

process of the stopped motor is much<br />

slower than that of a running motor, thus<br />

running and stopped cooling time constants<br />

setpoints are provided in the relay to<br />

reflect the difference.<br />

The TCU lower limit of the running cool<br />

down curve is defined by Hot/Cold Safe<br />

Stall Ratio and level of the motor load. The<br />

TCU lower limit of the stopped cool down<br />

curve is 0% and corresponds to motor at<br />

ambient temperature.<br />

Thermal Capacity Used<br />

100<br />

75<br />

50<br />

25<br />

0<br />

Time in Minutes<br />

Iavg @ 100% FLA<br />

Iavg @ 50% FLA<br />

0 50 100 150 200 250<br />

806810A3.cdr<br />

Exponential cooldown (hot/cold curve ratio 60%<br />

Start Inhibit and Emergency Restart<br />

The Start Inhibit function prevents starting<br />

of a motor when insufficient thermal<br />

capacity is available or motor start<br />

supervision function dictate the start<br />

inhibit. In case of emergency the thermal<br />

capacity used and motor start supervision<br />

timers can be reset to allow the hot motor<br />

starting.<br />

RTD Biasing<br />

The 469 thermal overload curves are<br />

based solely on measured current ,<br />

assuming a normal 40°C ambient and<br />

normal motor cooling. The actual<br />

motor temperature will increase due to<br />

unusually high ambient temperature, or<br />

motor cooling blockage. Use the RTD bias<br />

feature to augment the thermal model<br />

calculation of Thermal Capacity Used,<br />

if the motor stator has embedded RTDs.<br />

The RTD bias feature is feedback of<br />

measured stator temperature. This<br />

feedback acts to correct the assumed<br />

thermal model. Since RTDs have a relatively<br />

slow response, RTD biasing is useful for<br />

slow motor heating. Other portions of the<br />

thermal model are required during starting<br />

and heavy overload conditions when<br />

motor heating is relatively fast.<br />

For RTD temperatures below the RTD<br />

BIAS MINIMUM setting, no biasing occurs.<br />

For maximum stator RTD temperatures<br />

above the RTD BIAS MAXIMUM setting,<br />

the thermal memory is fully biased and<br />

forced to 100%. At values in between, if the<br />

RTD bias thermal capacity used is higher<br />

compared to the thermal capacity used<br />

created by other features of the thermal<br />

model, then this value is used from that<br />

point onward.<br />

Motor Start Supervision<br />

Motor Start Supervision consists of the<br />

following features: Time-Between-Starts,<br />

Start-per-Hour, Restart Time.<br />

These elements are intended to guard the<br />

motor against excessive starting duty,<br />

which is normally defined by the motor<br />

manufacturer in addition to the thermal<br />

damage curves.<br />

Mechanical Jam and Acceleration<br />

Time<br />

These two elements are used to prevent<br />

motor damage during abnormal<br />

operational conditions such as excessively<br />

long acceleration times or stalled rotor.<br />

Phase Differential Protection<br />

This function is intended to protect the<br />

stator windings and supply power<br />

cables of large motors. Two types of<br />

current transformers connections are<br />

supported:<br />

• 6 CT’s externally connected in the<br />

summing configuration.<br />

• 3 Flux Balancing CT’s.<br />

Separate trip pickup levels and time<br />

delays are provided for motor starting and<br />

running conditions.<br />

RTD Thermal Capacity Used (%)<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

RTD Bias Minimum<br />

RTD Bias Maximum<br />

RTD Bias Center<br />

Point<br />

-50 0 50 100 150 200 250<br />

Maximum Stator RTD Temperature (C)<br />

806809A4.cdr<br />

RTD Bias curve.<br />

Short Circuit Trip<br />

This function is intended to protect the<br />

stator windings of the motors against<br />

phase-to-phase faults.<br />

Equipped with an overreach filter, the<br />

Motor Protection<br />

www.GEDigitalEnergy.com<br />

399

469 Motor Protection System<br />

Motor Protection<br />

469 removes the DC component from<br />

the asymmetrical current present at the<br />

moment a fault occurs or motor starts.<br />

A trip backup feature is also available as<br />

part of this function, used to issue a second<br />

trip if the fault is not cleared within a given<br />

time delay.<br />

The backup feature can also be assigned<br />

to an auxiliary contact for annunciation<br />

or remote tripping of upstream protection<br />

devices<br />

Ground Fault<br />

This function is designed to protect motors<br />

against phase to ground faults.<br />

There are two dedicated ground current<br />

inputs in the relay, which support the<br />

following types of ground current<br />

detection.<br />

• Core balance (Zero sequence) current<br />

transformer.<br />

• Core balance (Zero sequence) 50:0.025<br />

A (sensitive) current transformer.<br />

• Residual connection of phase current<br />

transformers.<br />

The function is equipped with an overreach<br />

filter, which removes the DC component<br />

from the asymmetrical current present<br />

at the moment a fault occurs, or a motor<br />

starts. Two pickup levels ( trip and alarm)<br />

with individual time delays are available<br />

for ground fault detection.<br />

A trip Backup feature is also available<br />

as part of this function. The operational<br />

principal of Ground Fault Trip Backup is the<br />

same as of Short Circuit Trip Backup.<br />

<strong>Voltage</strong> and Frequency Protection<br />

Use the voltage and frequency protection<br />

functions to detect abnormal system<br />

voltage and frequency conditions,<br />

potentially hazardous to the motor.<br />

The following voltage elements are<br />

available:<br />

• Over and Undervoltage<br />

• Over and Underfrequency<br />

• Phase Reversal<br />

To avoid nuisance trips, the 469 can be set<br />

to block the undervoltage element when<br />

the bus that supplies power to the motor<br />

is de-energized, or under VT fuse failure<br />

conditions.<br />

Power Elements<br />

The following power elements are<br />

available in 469 relay. The first four<br />

elements have blocking provision during<br />

motor starting.<br />

Power Factor<br />

This element is used in synchronous motors<br />

applications to detect out-of-synchronism<br />

conditions.<br />

Reactive Power<br />

This element is used in applications where<br />

the reactive power limit is specified.<br />

Underpower<br />

Used to detect loss of load.<br />

Reverse Active Power<br />

Useful to detect conditions where the<br />

motor can become a generator.<br />

Overtorque<br />

This element is used to protect the driven<br />

load from mechanical breakage.<br />

Current Unbalance<br />

In addition to thermal model biasing<br />

current unbalance is available in the 469<br />

relay as an independent element with 2<br />

pickup levels and a built-in single phasing<br />

detection algorithm.<br />

RTD Protection<br />

The 469 has 12 programmable RTD<br />

inputs supporting 4 different types of RTD<br />

sensors. RTD inputs are normally used<br />

for monitoring stator, bearings, ambient<br />

temperature as well as other parts of the<br />

motor assembly that can be exposed<br />

to overheating. Each RTD input has 3<br />

operational levels: alarm, high alarm and<br />

trip. The 469 also supports RTD trip voting<br />

and provides open/short RTD failure<br />

alarms.<br />

Additional and Special Features<br />

• Two speed motor protection.<br />

• Load averaging filter for cyclic load<br />

applications<br />

• Reduced voltage starting supervision.<br />

• Variable frequency filter allowing<br />

accurate sensing and calculation of the<br />

analog values in <strong>VFD</strong> applications.<br />

• Analog input differential calculation for<br />

dual drives applications.<br />

• Speed counter trip and alarm.<br />

• Universal digital counter trip and alarm.<br />

• Pulsing KWh and Kvarh output.<br />

• Trip coil supervision.<br />

• Drawout indicator, Setpoints Access and<br />

Test permit inputs.<br />

• Undervoltage Autorestart (Optional)<br />

• Broken rotor bar detection system<br />

(Optional)<br />

• VT Fuse Failure<br />

Inputs and Outputs<br />

Current and <strong>Voltage</strong> Inputs<br />

The 469 has two sets of three phase CT<br />

inputs, one for phase current, and one<br />

dedicated for differential protection.<br />

The ratings of the phase current inputs (1A<br />

and 5A) must be specified when ordering<br />

the relay, while the ratings for differential<br />

inputs are field programmable, supporting<br />

both 1A and 5A secondary currents.<br />

There are also 2 single-phase ground CT<br />

inputs: A standard input with settable<br />

secondary rating; 5A or 1A, and a high<br />

sensitivity ground current detection input<br />

for high resistance grounded systems.<br />

Three phase VT inputs support delta and<br />

wye configuration and provide voltage<br />

signals for all voltage, frequency and power<br />

based protection elements and metering.<br />

Digital Inputs<br />

The 469 has 5 predefined inputs:<br />

• Starter Status<br />

• Emergency Restart<br />

• Remote Reset<br />

• Setpoint Access<br />

n Test Switch<br />

The 469 also has four assignable digital<br />

inputs, which can be configured as the<br />

following functions:<br />

400<br />

www.GEDigitalEnergy.com

469 Motor Protection System<br />

• Remote Trip and Alarm<br />

• Speed Switch Trip and Tachometer<br />

• Vibration Switch Trip and Alarm<br />

• Pressure Switch Trip and Alarm<br />

• Load Shed Trip<br />

• Universal Digital Counter<br />

• External oscillography trigger and<br />

External Relay Fault Simulation<br />

initiation<br />

• General Switch with programmable<br />

functions and outputs<br />

Analog Inputs and Outputs<br />

Use the four configurable analog inputs<br />

available in the 469 to measure motor<br />

operation related quantities fed to the<br />

relay from standard transducers. Each<br />

input can be individually set to measure<br />

4-20 mA, 0-20 mA or 0-1 mA transducer<br />

signals. The 469 can also be set to issue<br />

trip or alarm commands based on signal<br />

thresholds.<br />

Use the four configurable analog outputs<br />

available in the 469 to provide standard<br />

transducer signals to local monitoring<br />

equipment. The desired output signal must<br />

be specified when the relay is ordered,<br />

either 4-20 mA, or 0-1 mA. The analog<br />

outputs can be configured to provide<br />

outputs based on any measured analog<br />

value, or any calculated quantity.<br />

Output Relays<br />

There are six Form-C output relays<br />

available in the 469. Four relays are<br />

always non-failsafe and can be selectively<br />

assigned to perform trip, or alarm<br />

functions. A non-failsafe block start relay<br />

is also provided, controlled by protection<br />

functions requiring blocking functionality.<br />

Loss of control power or 469 internal<br />

failures are indicated via the failsafe<br />

service relay. The trip and alarm relays<br />

can also be configured with latching<br />

functionality.<br />

Monitoring and Metering<br />

The 469 includes high accuracy metering<br />

and recording for all AC signals. <strong>Voltage</strong>,<br />

current, RTD and power metering are built<br />

into the relay as a standard feature.<br />

Metering<br />

The following system values are accurately<br />

metered and displayed:<br />

• Phase, differential and ground currents,<br />

average current, motor load, current<br />

unbalance.<br />

• Phase-to-ground and Phase-to-phase<br />

voltages, average phase voltage,<br />

system frequency.<br />

• Real, reactive, apparent power, power<br />

factor, watthours, varhours, torque<br />

• Current and power demand.<br />

• Analog inputs and RTD temperatures.<br />

• Thermal capacity used, lockout times,<br />

motor speed<br />

Monitoring<br />

The 469 is equipped with monitoring tools<br />

to capture data. The following information<br />

is presented in a suitable format.<br />

• Status of inputs, outputs and alarms<br />

• Last trip data<br />

• Motor learned parameters: last and<br />

maximum acceleration times, starting<br />

currents and starting TCU, average<br />

currents, RTD maximums, analog inputs<br />

maximums and minimums.<br />

• Trip and general counters, motor<br />

running hours and start timers.<br />

• Event recorder<br />

• Oscillography<br />

Event Recorder<br />

The event recorder stores motor and<br />

system information with a date and time<br />

Motor Protection<br />

User Interface<br />

469 STATUS INDICATORS<br />

469 status<br />

Motor status<br />

Output relays<br />

LARGE DISPLAY<br />

Forty character display for viewing<br />

setpoints and actual value messages.<br />

Diagnostic messages are<br />

displayed when there is a trip or<br />

alarm condition. Default messages<br />

are displayed after a period of<br />

inactivity.<br />

NUMERIC KEYPAD<br />

Numeric keys allow for simple<br />

entry of setpoint values. Control<br />

keys allow simple navigation<br />

through setpoint and actual value<br />

message structures. Help key<br />

provides context sensitive help<br />

messages<br />

CONTROL AND<br />

PROGRAMMING KEYS<br />

Menu, Escape, Reset, Enter,<br />

Menu Up, and Menu Down<br />

keys for complete acess<br />

without a computer .<br />