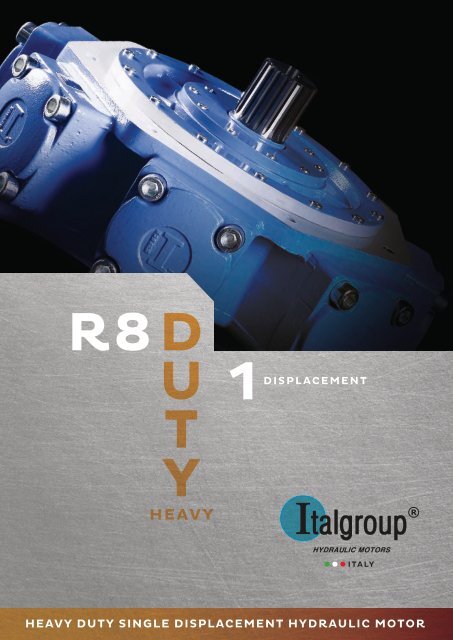

ITAL GROUP MOTOR R8D

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

R8<br />

D<br />

U<br />

TY<br />

1DISPLACEMENT<br />

HEAVY<br />

<strong>ITAL</strong>Y<br />

HEAVY DUTY SINGLE DISPLACEMENT HYDRAULIC <strong>MOTOR</strong>

<strong>R8D</strong> SERIES<br />

TECHNICAL CATALOGUE<br />

The data specified into the catalogue are for product description purpose only<br />

and must not be interpreted as warranted characteristics in legal sense.<br />

Italgroup S.r.l. reserves the right to implement modifications without notice.<br />

All partial or total reproduction and copy without written authorization of Italgroup<br />

S.r.l. is strictly forbidden.<br />

©2018 <strong>ITAL</strong><strong>GROUP</strong> S.R.L. - ALL RIGHTS RESERVED -<br />

<strong>R8D</strong> rev.01 - Jan. 2019

GENERAL INDEX<br />

FORMULAS Pag. 3<br />

INTRODUCTION - GENERAL INFORMATION Pag. 4 - 5<br />

<strong>MOTOR</strong> TECHNICAL DATA Pag. 6 - 7<br />

INTERCHANGEABILITY CHART Pag. 8<br />

<strong>R8D</strong> ORDERING CODE Pag. 9<br />

HYDRAULIC FLUID RECOMMENDATIONS Pag. 10 - 11<br />

DRAIN RECOMMENDATIONS - FLUSHING Pag. 12 - 13<br />

STANDARD SHAFT SEAL FEATURES Pag. 14 - 15<br />

<strong>MOTOR</strong> INSTALLATION AND STARTUP Pag. 16 - 18<br />

<strong>MOTOR</strong> HANDLING AND STORAGE Pag. 19 - 20<br />

MAINTENANCE OPERATION Pag. 21<br />

INSTRUCTION AND ADVICES Pag. 22<br />

SPECIAL FEATURES Pag. 23<br />

TROUBLESHOOTING Pag. 24 - 25<br />

UNIT CONVERSIONS Pag. 26<br />

<strong>R8D</strong> H2 Pag. 27 - 36<br />

<strong>R8D</strong> H3 Pag. 37 - 50<br />

<strong>R8D</strong> H4 Pag. 51 - 69<br />

<strong>R8D</strong> H45 Pag. 71 - 79<br />

<strong>R8D</strong> H5 Pag. 79 - 99<br />

<strong>R8D</strong> H55 Pag. 101 - 113<br />

<strong>R8D</strong> H6 Pag. 115 - 133<br />

<strong>R8D</strong> H7 Pag. 135 - 149<br />

<strong>R8D</strong> H8 Pag. 151 - 162<br />

<strong>R8D</strong> H9 Pag. 163 - 173<br />

<strong>MOTOR</strong> DISTRIBUTORS Pag. 174 - 175<br />

TACHOMETERS Pag. 177 - 180<br />

SPLINED BILLETS - SPLINED BARS Pag. 181 - 185<br />

ADAPTOR FLANGES Pag. 186 - 187<br />

VALVES Pag. 189 - 206<br />

CONTACT US - REACH US Pag. 207<br />

The data specified into the catalogue are for product description purpose only and must not be interpreted as warranted characteristics in legal sense. Italgroup S.r.l. reserves the<br />

right to implement modifications without notice. All partial or total reproduction and copy without written authorization of Italgroup S.r.l. is strictly forbidden.

<strong>ITAL</strong><strong>GROUP</strong> <strong>MOTOR</strong>S <strong>R8D</strong> SERIES TECHNICAL CATALOGUE<br />

<strong>R8D</strong> rev.01 - Jan. 2019

FORMULAS<br />

Torque [Nm]<br />

=<br />

Specific torque [Nm/bar]<br />

*<br />

Pressure [bar]<br />

Torque [Nm]<br />

=<br />

Displacement [cc/Rev]<br />

62.8<br />

*<br />

Pressure [bar]<br />

Power [kW]<br />

=<br />

Torque [Nm]<br />

*<br />

9549<br />

Speed [rpm]<br />

Power [CV]<br />

=<br />

Torque [Nm]<br />

*<br />

7023<br />

Speed [rpm]<br />

Speed [rpm]<br />

=<br />

Flow [l/min] * 1000<br />

Displacement [cc/Rev]<br />

Displacement [cc/Rev]<br />

=<br />

Torque [Nm]<br />

*<br />

Pressure [bar]<br />

62,8<br />

Flow [l/min]<br />

=<br />

Displacement [cc/Rev] * Speed [rpm]<br />

1000<br />

The data specified into the catalogue are for product description purpose only and must not be interpreted as warranted characteristics in legal sense. Italgroup S.r.l. reserves the<br />

right to implement modifications without notice. All partial or total reproduction and copy without written authorization of Italgroup S.r.l. is strictly forbidden.<br />

3

<strong>ITAL</strong><strong>GROUP</strong> <strong>MOTOR</strong>S <strong>R8D</strong> SERIES TECHNICAL CATALOGUE<br />

INTRODUCTION<br />

GENERAL INFORMATION<br />

Carefully read the use and maintenance manual before start-up the motor. The<br />

use and maintenance manual must be placed near to motor installation location<br />

in order to guarantee operators easy access to the instruction manual. For further<br />

information please contact Italgroup.<br />

<strong>MOTOR</strong> DESCRIPTION<br />

<strong>R8D</strong> series motors are radial piston hydraulic motors (generally indicated as LSHT motors,<br />

low speed high torque motors) with a rotating shaft (1) and a stationary housing (2). The pistons<br />

(4) are located radially and the working fluid provide the mechanical force that push<br />

the pistons against the eccentric shaft, providing the shaft ouput torque. The inlet and outlet<br />

flow to and from the pistons is regulated by a distributor (5), that provides the oil distribution<br />

correct timing. The pistons transfer the forces to the eccentric shaft through a connecting rod<br />

(3). Acting in the adequate way (increasing or reducing the oil flow coming from the pump)<br />

the motor rotational speed can be increased or reduced. The motor design guarantee extremely<br />

high starting torque and high mechanical working efficiency. Respecting the limitation<br />

of working parameters (indicated into the technical datasheets) and all recommendations (including<br />

fluid recommendations), high motor lifetimes are obtained and very low maintenance<br />

requirements are needed.<br />

4<br />

3<br />

2<br />

5<br />

1<br />

4<br />

<strong>R8D</strong> rev.01 - Jan. 2019

<strong>R8D</strong> SERIES<br />

Hydraulic motors of the <strong>R8D</strong> series are single displacement crankshaft radial piston motors. Thanks to great<br />

variety of accessories <strong>R8D</strong> series can be used in a wide range of applications such as:<br />

• marine equipments<br />

• winches<br />

• offshore equipments<br />

• conveyors<br />

• injection moulding machines<br />

• steel bending machines<br />

• fork lifts trucks<br />

• skid steer loaders<br />

• dumpers<br />

• agricultural and forestry machines<br />

• municipal vehicles<br />

• airport machinery<br />

PRODUCT FEATURES:<br />

High volumetric and mechanical efficiencies<br />

Very smooth running at low speeds<br />

High starting torque / constant torque<br />

Wide speed range<br />

Compact Design<br />

Low maintenance and high reliability<br />

Bi-directional<br />

High radial and axial force allowed<br />

Speed sensor available<br />

Built-in valves available<br />

The data specified into the catalogue are for product description purpose only and must not be interpreted as warranted characteristics in legal sense. Italgroup S.r.l. reserves the<br />

right to implement modifications without notice. All partial or total reproduction and copy without written authorization of Italgroup S.r.l. is strictly forbidden.<br />

5

<strong>ITAL</strong><strong>GROUP</strong> <strong>MOTOR</strong>S <strong>R8D</strong> SERIES TECHNICAL CATALOGUE<br />

<strong>MOTOR</strong> TECHNICAL DATA<br />

Motor Size Displacement Theoretical<br />

torque<br />

Max cont.<br />

pressure<br />

Max cont.<br />

speed<br />

Peak speed<br />

(**)<br />

Max cont.<br />

power (*)<br />

Max<br />

power<br />

Dry<br />

weight<br />

[cc] [Nm/bar] [bar] [rpm] [rpm] [kW] [kW] [kg]<br />

<strong>R8D</strong> 300 H2 314 5 270 900 1100 45 66 42<br />

<strong>R8D</strong> 350 H3 342 5.4 270 850 950 85 130 68<br />

<strong>R8D</strong> 400 H3 398 6.3 270 750 860 85 130 68<br />

<strong>R8D</strong> 450 H3 452 7.2 270 650 760 85 130 68<br />

<strong>R8D</strong> 500 H3 492 7.8 270 600 690 85 130 68<br />

<strong>R8D</strong> 600 H3 594 9.5 270 500 570 85 130 68<br />

<strong>R8D</strong> 700 H3 707 11.2 170 440 500 78 118 68<br />

<strong>R8D</strong> 500 H4 493 7.8 270 700 800 130 160 92<br />

<strong>R8D</strong> 600 H4 584 9.3 270 700 800 130 160 92<br />

<strong>R8D</strong> 700 H4 714 11.4 270 500 580 130 160 92<br />

<strong>R8D</strong> 800 H4 792 12.6 270 450 530 130 160 92<br />

<strong>R8D</strong> 850 H4 847 13.5 270 420 490 130 160 92<br />

<strong>R8D</strong> 900 H4 904 14.4 270 400 460 130 160 92<br />

<strong>R8D</strong> 1000 H4 992 15.8 270 355 405 130 160 92<br />

<strong>R8D</strong> 1250 H4 1247 19.8 200 280 320 102 130 92<br />

<strong>R8D</strong> 1100 H45 1182 18.8 250 400 450 158 190 120<br />

<strong>R8D</strong> 1400 H45 1376 21.9 250 350 400 158 190 120<br />

<strong>R8D</strong> 900 H5 941 15 270 550 600 178 210 173<br />

<strong>R8D</strong> 1000 H5 1094 17.4 270 500 550 178 210 173<br />

<strong>R8D</strong> 1200 H5 1231 19.6 270 450 510 178 210 173<br />

<strong>R8D</strong> 1400 H5 1376 21.9 270 410 470 178 210 173<br />

<strong>R8D</strong> 1500 H5 1528 24.3 270 390 450 178 210 173<br />

<strong>R8D</strong> 1600 H5 1648 26.2 270 370 425 178 210 173<br />

<strong>R8D</strong> 1800 H5 1815 28.9 250 340 390 178 210 173<br />

<strong>R8D</strong> 2000 H5 2034 32.4 190 280 310 140 160 173<br />

<strong>R8D</strong> 1800 H55 1800 28.7 270 265 290 190 220 203<br />

<strong>R8D</strong> 2000 H55 1962 31.2 270 245 270 190 220 203<br />

<strong>R8D</strong> 2100 H55 2035 32.4 270 235 260 190 220 203<br />

<strong>R8D</strong> 2150 H55 2126 33,8 270 235 260 190 220 203<br />

<strong>R8D</strong> 2200 H55 2193 34,9 270 220 240 190 220 203<br />

<strong>R8D</strong> 2300 H55 2293 36.5 250 210 235 180 210 203<br />

<strong>R8D</strong> 2400 H55 2393 38.1 250 190 220 170 210 203<br />

<strong>R8D</strong> 1800 H6 1866 29.7 270 350 400 220 245 308<br />

<strong>R8D</strong> 2000 H6 1993 31.7 270 350 400 220 245 308<br />

<strong>R8D</strong> 2200 H6 2206 35.1 270 325 375 220 245 308<br />

<strong>R8D</strong> 2500 H6 2525 40.2 270 285 325 220 245 308<br />

<strong>R8D</strong> 2800 H6 2807 44.7 270 250 290 220 245 308<br />

<strong>R8D</strong> 3000 H6 2983 47.5 270 235 270 220 245 308<br />

<strong>R8D</strong> 3200 H6 3289 52.4 270 210 240 220 245 308<br />

<strong>R8D</strong> 3500 H6 3479 55.4 270 200 230 210 235 308<br />

6<br />

<strong>R8D</strong> rev.01 - Jan. 2019

Motor Size Displacement Theoretical<br />

torque<br />

Max cont.<br />

pressure<br />

Max cont.<br />

speed<br />

Peak<br />

speed (**)<br />

Max cont.<br />

power (*)<br />

Max<br />

power<br />

Dry<br />

weight<br />

[cc] [Nm/bar] [bar] [rpm] [rpm] [kW] [kW] [kg]<br />

<strong>R8D</strong> 3400 H7 3413 54.3 270 200 220 238 265 405<br />

<strong>R8D</strong> 3600 H7 3650 58.1 270 185 210 238 265 405<br />

<strong>R8D</strong> 3900 H7 3907 62.2 270 175 200 238 265 405<br />

<strong>R8D</strong> 4300 H7 4343 69.1 270 160 190 238 265 405<br />

<strong>R8D</strong> 4600 H7 4616 73.5 270 150 190 238 265 405<br />

<strong>R8D</strong> 5000 H7 5088 81.0 270 140 180 238 265 405<br />

<strong>R8D</strong> 5400 H7 5384 85.7 270 130 170 230 258 405<br />

<strong>R8D</strong> 3000 H8 3020 48.1 270 240 300 215 236 590<br />

<strong>R8D</strong> 6000 H8 5966 95 250 120 140 215 236 590<br />

<strong>R8D</strong> 6500 H8 6581 104.7 250 120 140 215 236 590<br />

<strong>R8D</strong> 6800 H8 6962 110.8 250 120 140 215 236 590<br />

<strong>R8D</strong> 7600 H8 7620 121.3 250 90 100 215 236 590<br />

<strong>R8D</strong> 8000 H8 8062 128.3 240 80 90 215 236 590<br />

<strong>R8D</strong> 7000 H9 7050 112 270 160 190 330 370 750<br />

<strong>R8D</strong> 8000 H9 8332 132.6 270 135 160 330 370 750<br />

<strong>R8D</strong> 9000 H9 8757 139.4 260 130 155 330 370 750<br />

<strong>R8D</strong> 10000 H9 10214 162.6 250 110 135 330 370 750<br />

<strong>R8D</strong> 11000 H9 11016 175.3 250 105 120 330 370 750<br />

<strong>R8D</strong> 12000 H9 12073 192,2 250 95 110 330 370 750<br />

<strong>R8D</strong> 13000 H9 13020 207.3 250 90 105 330 370 750<br />

For all motors:<br />

- Hydrostatic test pressure: 420 bar<br />

- Refer to motor performance diagrams for more information<br />

- (*) For motor operation with a continuous duty cycle at maximum continuous power the flushing is usually required.<br />

For more information please contact our technical department.<br />

- (**) Do not exceed maximum power.<br />

The data specified into the catalogue are for product description purpose only and must not be interpreted as warranted characteristics in legal sense. Italgroup S.r.l. reserves the<br />

right to implement modifications without notice. All partial or total reproduction and copy without written authorization of Italgroup S.r.l. is strictly forbidden.<br />

7

<strong>ITAL</strong><strong>GROUP</strong> <strong>MOTOR</strong>S <strong>R8D</strong> SERIES TECHNICAL CATALOGUE<br />

INTERCHANGEABILITY CHART<br />

Italgroup motor code<br />

Cross reference motor code<br />

<strong>R8D</strong> 450/B30 HMB 30<br />

<strong>R8D</strong> 800/B45 HMB 45<br />

<strong>R8D</strong> 1000 H5 - <strong>R8D</strong> 1000/B60 H5 HMB 60<br />

<strong>R8D</strong> 1400 H5 - <strong>R8D</strong> 1400/B80 H5 HMB 80<br />

<strong>R8D</strong> 1600 H5 - <strong>R8D</strong> 1600/B100 H5 HMB 100<br />

<strong>R8D</strong> 2150 H55 HMB 125<br />

<strong>R8D</strong> 2200 H6 - <strong>R8D</strong> 2200/B125 H6 HMB 125<br />

<strong>R8D</strong> 2500 H6 - <strong>R8D</strong> 2500/B150 H6 HMB 150<br />

<strong>R8D</strong> 3000 H6 - <strong>R8D</strong> 3000/B200 H6 HMB 200<br />

<strong>R8D</strong> 4600 H7 HMB 270<br />

<strong>R8D</strong> 5400 H7 HMB 325<br />

<strong>R8D</strong> 350-450-500/C H3 MR 350 - MR 450 - MRE 500<br />

<strong>R8D</strong> 600-700-800/C H4 MR 600 - MR 700 - MRE 800<br />

<strong>R8D</strong> 1100-1400/C H45 MR 1100 - MRE 1400<br />

<strong>R8D</strong> 1000-1400-1600/C1100 H5 MR 1100 - MRE 1400 - MR 1600<br />

<strong>R8D</strong> 1600-1800-2000/C H5 MR 1600 - MR 1800 - MRE 2100<br />

<strong>R8D</strong> 1800-2100-2400/MR1800 H55 MR 1800 - MRE 2100 - MRA 2400<br />

<strong>R8D</strong> 2500-2800-3000-3500/C H6 MR 2400 - MR 2800 - MRE 3100 MRA 3500<br />

<strong>R8D</strong> 3600-4500-5400/C H7 MR 3600 - MR 4500 - MRE 5400<br />

<strong>R8D</strong> 6500-6800-8000/C H8 MR 6500 - MR 7000 - MRE 8200<br />

<strong>R8D</strong> 450-500/RM H3 RM 450 - RM 500<br />

<strong>R8D</strong> 900/RM H5 RM 900<br />

<strong>R8D</strong> 5000/RM H7 RM 5000<br />

<strong>R8D</strong> H2/GM2<br />

GM2<br />

<strong>R8D</strong> H4/GM4<br />

GM4<br />

<strong>R8D</strong> H5/GM5<br />

GM5<br />

<strong>R8D</strong> H6/GM6<br />

GM6<br />

<strong>R8D</strong> H2/S<br />

M2<br />

<strong>R8D</strong> H3/S<br />

M3<br />

<strong>R8D</strong> H4/S<br />

M4<br />

8<br />

<strong>R8D</strong> rev.01 - Jan. 2019

<strong>R8D</strong> - ORDERING CODE<br />

<strong>R8D</strong> - - - - - - - - - - - - - - - -<br />

DISPLACEMENT<br />

300<br />

See pag. 27-36<br />

350<br />

500<br />

400<br />

600<br />

See pag. 37-50<br />

500<br />

800<br />

1000<br />

600<br />

850<br />

See pag. 51-69<br />

1250<br />

450<br />

700<br />

700<br />

900<br />

INTERCHANGEABILITY<br />

/GM2<br />

/C<br />

/C<br />

/GM4<br />

/H4C<br />

/SB506<br />

/S<br />

/RM<br />

/B45<br />

/S<br />

SERIE<br />

H2<br />

H3<br />

H4<br />

1100 1400<br />

/C H45<br />

See pag. 71-78<br />

SHAFT<br />

A0 A01<br />

A1 A11<br />

A12 A13<br />

A2 A21<br />

A22 A23<br />

A3 A31<br />

A32 A33<br />

A34 A4<br />

A5<br />

TACHOMETER<br />

TA<br />

TB<br />

TT1<br />

TQ1<br />

EST<br />

EST30<br />

EST31<br />

EST32<br />

EST33<br />

See pag. 177-180<br />

SPECIAL<br />

FEATURES<br />

MP<br />

SPSL<br />

HPS<br />

CCW<br />

See pag. 23<br />

Z - -<br />

Italgroup<br />

internal code<br />

900<br />

1000<br />

1200<br />

/C1100<br />

/C<br />

H5<br />

1400 1500 1600<br />

1800 2000<br />

See pag. 79-99<br />

/B60 /B80<br />

/B100 /GM5<br />

/S /RM<br />

DISTRIBUTOR<br />

D31B D31BJ<br />

D36B D36BJ<br />

SPLINED BILLET / SPLINED BAR<br />

SB2 SB3<br />

SB4 SB5<br />

1800<br />

2150<br />

2000<br />

2200<br />

2400<br />

2100<br />

2300<br />

/MR1800<br />

See pag. 101-113<br />

1800 2000 2200 /C /B125<br />

2500 2800 3000 /B150 /B200<br />

3200 3500 /GM6 /PL<br />

See pag. 115-133<br />

3400 3600 3900 /C /RM<br />

H55<br />

H6<br />

H7<br />

D310B D310BJ<br />

D40 D40J<br />

D47 D47J<br />

D416 D416J<br />

D75 D75J<br />

D90 D90J<br />

D200 D200J<br />

D202 D202J<br />

See pag. 174-175<br />

SB6 SB7<br />

SB8 SB9<br />

SB10 SB11<br />

SB12 SB16<br />

SB17 SB21<br />

SB22 SB24<br />

SB27 SB30<br />

B8076 B8078<br />

B8079<br />

See pag. 181-185<br />

4300<br />

4600 5000<br />

5400<br />

See pag. 135-149<br />

3000<br />

6800<br />

6000<br />

7600<br />

6500<br />

8000<br />

See pag. 151-162<br />

7000 8000 9000<br />

10000 11000 12000<br />

13000<br />

See pag. 163-173<br />

/C<br />

/C<br />

H8<br />

H9<br />

The data specified into the catalogue are for product description purpose only and must not be interpreted as warranted characteristics in legal sense. Italgroup S.r.l. reserves the<br />

right to implement modifications without notice. All partial or total reproduction and copy without written authorization of Italgroup S.r.l. is strictly forbidden.<br />

9

<strong>ITAL</strong><strong>GROUP</strong> <strong>MOTOR</strong>S <strong>R8D</strong> SERIES TECHNICAL CATALOGUE<br />

HYDRAULIC FLUID RECOMMENDATIONS<br />

Fluid selection<br />

Optimal viscosity selection<br />

In general, we recommend the use of hydraulic oils with minimum viscosity<br />

index of 95, with anti-wear additives (ISO HM and HV). Once normal working<br />

temperature is reached, the drain oil viscosity must be at least 35-40 cSt,<br />

preferably in the range from 40 to 60 cSt.<br />

HE oils (ecological fluids) are allowed, but must be used with particular attention,<br />

because them can influence the motor seals compatibility, and can<br />

reduce motor performances and life. Please contact us in case of HE oils<br />

usage.<br />

Referring the first approximated selection to the room temperature, we advice<br />

the following:<br />

Room temperature<br />

-20°C/0°C BP ENERGOL HLP – HM 22<br />

-15°C/+5°C BP ENERGOL HLP – HM 32<br />

-8°C/+15°C BP ENERGOL HLP – HM 46<br />

0°C/+22°C BP ENERGOL HLP – HM 68<br />

+8°C/+30°C BP ENERGOL HLP – HM 100<br />

Oil<br />

-20°C/+5°C BP BARTRAN HV 32<br />

-15°C/+22°C BP BARTRAN HV 46<br />

0°C/+30°C BP BARTRAN HV 68<br />

ATF (automatic transmission fluid) oils, SAE 10-20-30 W oils, multigrade<br />

motor oils (SAE 15 W 40, 10 W 40), universal oils, can also be used.<br />

Always fill the motor (please refer to the “DRAIN RECOMMENDATIONS”<br />

section) with the selected hydraulic fluid before motor start-up. During<br />

cold start-up avoid high-speed operation until the system reach<br />

the working temperature, in order to provide an adequate lubrication.<br />

Every 5-8 °C of increase respect to the optimal working temperature<br />

for the selected oil, the hydraulic fluid life decrease of about<br />

40-50% (refer to “OXIDATION” section). Consequently, the motor<br />

lifetime will be affected by the working temperature increase<br />

respect to the optimal working temperature of the selected oil.<br />

The maximum continuous working temperature is 70 °C, the temperature<br />

must be measured from motor drain line. If the motor doesn’t have<br />

a drain line, the temperature must be evaluated at the return line port.<br />

Fire resistant oil limitations<br />

Max cont.<br />

Pressure<br />

[bar]<br />

Max int.<br />

Pressure<br />

[bar]<br />

Max<br />

Speed<br />

[rpm]<br />

HFA, 5-95% oil-water 103 138 50%<br />

HFB, 60-40% oil-water 138 172 100%<br />

HFC, water-glycol 103 138 50%<br />

HFD, ester phosphate 250 293 100%<br />

10<br />

<strong>R8D</strong> rev.01 - Jan. 2019

Filtration<br />

Hydraulic systems oil must always be filtered.<br />

The choice of filtration grade derives from needs of service life and money<br />

spent. In order to obtain stated service life it is important to follow our recommendations<br />

concerning filtration grade.<br />

When choosing the filter it is important to consider the amount of dirt particles<br />

that filter can absorb and still operate satisfactorily. For that reason we recommend<br />

filters showing when you need to substitute filtering cartridge.<br />

· 25 μm filtration required in most applications<br />

· 10 μm filtration in closed circuit applications<br />

Oxidation<br />

Hydraulic oil oxidizes with time of use and temperature. Oxidation causes<br />

changes in colour and smell, acidity increase or sludge formation in the tank.<br />

Oxidation rate increases rapidly at surface temperatures above 60°C, in these<br />

situations oil should be checked more often.<br />

The oxidation process increases the acidity of the fluid; the acidity is stated in<br />

terms of the “neutralization number”. Oxidation is usually slow at the beginning<br />

and then it increases rapidly.<br />

A sharp increase (by a factor of 2 to 3) in neutralization number between<br />

inspections shows that oil has oxidized too much and should be replaced<br />

immediately.<br />

Water content<br />

Oil contamination by water can be detected by sampling from the bottom of<br />

the tank. Most hydraulic oils repel the water, which then collects at the bottom<br />

of the tank. This water must be drained off at regular intervals. Certain types<br />

of transmission oils and engine oils emulsify the water; this can be detected<br />

by coatings on filter cartridges or a change in the colour of the oil. In such<br />

cases, obtain your oil supplier advice.<br />

Degree of contamination<br />

Heavy contamination of the oil causes wear rising in hydraulic system components.<br />

Contamination causes must be immediately investigated and remedied.<br />

Analysis<br />

It is recommended oil being analyzed every 6 months. The analysis should<br />

cover viscosity, oxidation, water content, additives and contamination. Most<br />

oil suppliers are equipped to analyze oil state and to recommend appropriate<br />

action. Oil must be immediately replaced if the analysis shows that it is exhausted.<br />

The data specified into the catalogue are for product description purpose only and must not be interpreted as warranted characteristics in legal sense. Italgroup S.r.l. reserves the<br />

right to implement modifications without notice. All partial or total reproduction and copy without written authorization of Italgroup S.r.l. is strictly forbidden.<br />

11

<strong>ITAL</strong><strong>GROUP</strong> <strong>MOTOR</strong>S <strong>R8D</strong> SERIES TECHNICAL CATALOGUE<br />

DRAIN RECOMMENDATIONS<br />

<strong>MOTOR</strong> AXIS HORIZONTAL<br />

Leakage line<br />

Leakage line<br />

Check valve<br />

1 bar setting<br />

Plug<br />

Plug<br />

50 min<br />

50 min<br />

<strong>MOTOR</strong> AXIS VERTICAL, SHAFT DOWN<br />

50 min<br />

Leakage line<br />

50 min<br />

Plug<br />

Leakage line<br />

Plug<br />

50 min<br />

50 min<br />

50 min<br />

50 min<br />

50 min<br />

Check valve<br />

1 bar setting<br />

50 min<br />

50 min<br />

<strong>MOTOR</strong> AXIS VERTICAL, SHAFT UP<br />

Leakage line using<br />

an additional drain<br />

(on request)<br />

50 min<br />

50 min<br />

50 min<br />

Leakage line using<br />

an additional drain<br />

(on request)<br />

Leakage line<br />

Plug<br />

Plug<br />

Plug Plug Check valve Plug<br />

1 bar setting<br />

Check valve<br />

1 bar setting<br />

LEAKAGE LINE CONNECTION<br />

Always fill the motor with hydraulic fluid before start-up. Arrange piping in a way that the motor cannot<br />

drain off and cannot generates air bubbles into the motor case. Under certain conditions may be is necessary<br />

to arrange a check valve in order to help avoiding the motor drain off. Always check carefully that the<br />

leakage line pressure doesn’t overcome 10 bar pressure: therefore leakage lines must be shorter as possible<br />

and with a minimum flow resistance.<br />

12<br />

<strong>R8D</strong> rev.01 - Jan. 2019

FLUSHING<br />

Motor<br />

Flushing flow [l/min]<br />

<strong>R8D</strong> H2 5<br />

<strong>R8D</strong> H3 8<br />

<strong>R8D</strong> H4 10<br />

<strong>R8D</strong> H45 - <strong>R8D</strong> H5 15<br />

<strong>R8D</strong> H55 - <strong>R8D</strong> H6 - <strong>R8D</strong> H7 - <strong>R8D</strong> H8 - <strong>R8D</strong> H9 20<br />

Important note: the above value are approximated. The correct way to operate is the following: the flushing flow is<br />

adequate if during the motor operation the drain oil viscosity be at least 35-40 cSt, preferably in the range from 40 to<br />

60 cSt.<br />

Maximum continuous case pressure 6 bar (10 bar peak pressure). Special seals for 20-25 bar continuous case pressure<br />

are available upon request (ordering code: HPS).<br />

FLUSHING OUTLET PORT<br />

Please note: the flushing outlet port<br />

must always be located in the highest<br />

possible position.<br />

MAXIMUM CASE PRESSURE<br />

6 bar continuous<br />

10 bar peak<br />

For standard <strong>R8D</strong> motors<br />

FLUSHING<br />

INLET PORT<br />

The data specified into the catalogue are for product description purpose only and must not be interpreted as warranted characteristics in legal sense. Italgroup S.r.l. reserves the<br />

right to implement modifications without notice. All partial or total reproduction and copy without written authorization of Italgroup S.r.l. is strictly forbidden.<br />

13

<strong>ITAL</strong><strong>GROUP</strong> <strong>MOTOR</strong>S <strong>R8D</strong> SERIES TECHNICAL CATALOGUE<br />

STANDARD SHAFT SEAL FEATURES<br />

Features<br />

Type: BABSL<br />

Form: AS DIN 3760<br />

Material: SIMRIT® 72 NBR 902<br />

SIMRIT® 75 FKM 595<br />

Material<br />

SIMMERRING® radial shaft seal with rubber covered O.D., short,<br />

flexibility suspensed, spring loaded sealing lip and additional dust<br />

lip:<br />

see Part B/SIMMERRING®, sections 1.1 and 2.<br />

Application<br />

Sealing lip and O.D.:<br />

– Acrylonitrile-butadiene rubber with 72<br />

Shore A hardness (designation: SIMRIT® 72 NBR 902)<br />

– Fluoro rubber with 75 Shore A hardness<br />

(designation: SIMRIT®75 FKM 595)<br />

Metal insert:<br />

– Plain steel DIN 1624<br />

Spring:<br />

– Spring steel DIN 17223<br />

Operating conditions See Part B/ SIMMERRING®, sections 2. 4.<br />

Media: mineral oils, synthetic oils<br />

Temperature:<br />

-40°C to +100°C (SIMRIT® 72 NBR 902)<br />

-40°C to +160°C (SIMRIT® 75 FKM 595)<br />

Surface speed: up to 5 m/s<br />

Working pressure: see diagram on next page, pressure is function of<br />

surface speed (i.e. of rotating speed and shaft diameter)<br />

14<br />

<strong>R8D</strong> rev.01 - Jan. 2019

Housing and machining<br />

criteria<br />

See Part B/ SIMMERRING®, sections 2.<br />

Shaft:<br />

Tolerance: ISO h11<br />

Concentricity: IT 8<br />

Roughness: Ra=0.2-0.8 μm<br />

Rz=1-4 μm<br />

Rmax=6 μm<br />

Hardness:<br />

45-60 HRc<br />

Roughness: non oriented;<br />

preferably by plunge grinding<br />

Housing:<br />

Tolerance:<br />

Roughness:<br />

ISO H8<br />

Rmax

<strong>ITAL</strong><strong>GROUP</strong> <strong>MOTOR</strong>S <strong>R8D</strong> SERIES TECHNICAL CATALOGUE<br />

<strong>MOTOR</strong> INSTALLATION AND STARTUP<br />

Motor installation and<br />

start-up<br />

The motor, after testing, it’s packed in different ways that depends by customer<br />

and/or logistic requirements. The motor must be carefully moved<br />

from his box or pallet, with the assistance of correctly sized movimentation<br />

tools, like eyebolts (all the motors has a thread hole in the shaft end,<br />

please refer to the <strong>R8D</strong> general catalogue, shafts section) or lifting slings.<br />

When the motor is moved from one place to another always be very careful<br />

and act in a way that the motor is stable and under control during<br />

movimentation (refer to handling and storage section for more details).<br />

Before mount the motor, check carefully the absence of damage happened<br />

for example during transportation and/or storing.<br />

For mounting dimensions please refer to the <strong>R8D</strong> installation drawings. The<br />

motor must be installed using the correct screws size (we recommends the<br />

use of 10.9 and 12.9 class resistance fixing screws) and must be placed on<br />

a structure that is capable to correctly support the motor during functioning:<br />

for this reason the structure must not only be able to support the motor<br />

weight but must also assure the absence of vibration during operation and<br />

must win the reaction forces that are generated by the working torque. Regarding<br />

the motor fitting design, the concentricity between the centering<br />

diameter (spigot) and shaft (both splined or parallel) must be assured with a<br />

strict tolerance (please refer to the following general indication). If the concentricity<br />

between the shaft and the centering diameter and/or fixing holes<br />

is not respected, in the worst case the motor can have an unusual failure or<br />

can work only with low performances. Splined adaptors (splined billets) are<br />

available upon request.<br />

C<br />

Ø0,15 A B<br />

C<br />

D<br />

ØA H6<br />

ØB<br />

0,05<br />

0,05 A<br />

0,05 B<br />

ØB<br />

ØA<br />

D<br />

B<br />

3.2<br />

3.2<br />

A<br />

F<br />

E<br />

E+1 +1 0<br />

0.1<br />

F+1 +1 0<br />

16<br />

<strong>R8D</strong> rev.01 - Jan. 2019

Hoses and piping must be clean and free from contamination. Use proper<br />

hoses for oil connection, both for inlet and outlet main ports, and for drain line.<br />

Refer to hoses and fitting constructors in order to correctly size and select hoses<br />

and fittings. In order to keep control on the oil compressibility keep hoses<br />

to the minimum recommended size and select pipelines most rigid as possible.<br />

The motor can be mounted in any position (refer also to drain recommendations<br />

section). In run-away conditions you must use counterbalance valves.<br />

When the motor is installed vertically with shaft pointing upwards, consult our<br />

technical department. If the motor is connected to high inertial loads, the hydraulic<br />

system must be designed to prevent peaks of pressure and cavitation.<br />

Consider the use of relief valves, possibly directly mounted on motor distributor<br />

in case the application can generates pressure peaks at the motor ports: the<br />

relief valve should be able to discharge all the flow (or at least a good part of<br />

it) with a limited pressure increase. Italgroup can provide differents valve types<br />

that can be placed directly on the motor distributor (please refer to Italgroup<br />

valves technical catalogue).<br />

Motor case and pistons must be completely filled with oil before starting.<br />

Do not load motor to maximum working pressure instantly. During cold start-up<br />

avoid high-speed operation until the system reach the working temperature.<br />

Connect the case drain directly to tank, and avoid excessive drain line pressure<br />

losses (the case drain pressure must not exceed 10 bar continuous pressure for<br />

<strong>R8D</strong> serie standard motors). The case drain port on the motor must be located<br />

on the highest point of the installation to ensure that the motor will always be<br />

full of oil. (See drain recommendations page for more details)<br />

Maximum oil temperature must not exceed 70°C. Heath exchangers must be<br />

used with higher temperatures. The operating fluid viscosity must always be<br />

higher than a certain minimum value (see “fluid recommendation” section) in<br />

order to guarantee an optimal motor internal lubrication. When the working<br />

conditions cause the motor case overheating above a critical value, the motor<br />

flushing is required. Flushing consists in the introduction of fresh oil (taken from<br />

the hydraulic circuit) into the motor case. Oil must be taken from the return line<br />

to avoid internal motor damage (the continuous motor case pressure must be<br />

maximum 6 bar). Flushing is an important operation that can be very effective<br />

to improve motor lifetime with heavy duty working conditions and improve the<br />

motor mechanical efficiency.<br />

The motor flushing, if the motor works in one direction only, can be easily<br />

performed connecting the motor return line to the lowest motor drain port. The<br />

highest motor drain port must be connected to the tank. For D75 and D90 flow<br />

distributors, the side 1/4” metallic plugs can be used for flushing circuit installation:<br />

infact the plug (corresponding to the return line port) can be removed<br />

and the connection between motor low pressure port and motor case can be<br />

correctly realized.<br />

The data specified into the catalogue are for product description purpose only and must not be interpreted as warranted characteristics in legal sense. Italgroup S.r.l. reserves the<br />

right to implement modifications without notice. All partial or total reproduction and copy without written authorization of Italgroup S.r.l. is strictly forbidden.<br />

17

<strong>ITAL</strong><strong>GROUP</strong> <strong>MOTOR</strong>S <strong>R8D</strong> SERIES TECHNICAL CATALOGUE<br />

<strong>MOTOR</strong> INSTALLATION AND STARTUP<br />

If the motor axis is not horizontal and/or the motor works in bidirectional<br />

operation, please contact Italgroup technical department, that can assist<br />

you to advice how to perform the desired operation in the best way. Just<br />

for your reference, Italgroup can provide you flushing valves in order to<br />

perform an effective flushing circuit.<br />

Minimum speed is very low and can reach values near to 0.5-1 rpm (depending<br />

on motor displacement). In case of low speed vibration a reasonable<br />

back pressure can eliminate or minimize the vibration and noise level (a<br />

general guideline value can be defined by 5-8 bar back pressure). For<br />

more information please contact our technical department.<br />

Back pressure limit for <strong>R8D</strong> series motors is 70-80 bar (back pressure occurs<br />

for example when hydraulic motors are installed in series circuit). High<br />

back pressure values are often responsible of motor overheating, so if drain<br />

temperature reach values that bring the oil viscosity under the recommended<br />

limit (refer to fluid recommendations section), perform appropriate motor<br />

flushing and/or reduce the back pressure.<br />

During start-up and in the period immediately after it, any hydraulic installation<br />

must be regurarly and carefully checked at frequent intervals. The<br />

working pressure must be checked in order to understand that it agrees<br />

with the design values. The drain line pressure for standard motors must<br />

not overcome 10 bar continuous. If leakage occurs, check the reason,<br />

correct it and carry out new measurements. Check all lines, connections,<br />

screws, etc, and tighten if necessary. Replace contaminated fluid immediately.<br />

The motor installation and start-up must be performed by instructed and<br />

experienced personnel only.<br />

Please contact us freely to obtain further information.<br />

18<br />

<strong>R8D</strong> rev.01 - Jan. 2019

<strong>MOTOR</strong> HANDLING AND STORAGE<br />

Motor handling<br />

The motor must be correctly packed during transport and correctly stored into<br />

the warehouse in order to avoid eventual damages that can make the motor<br />

functioning not adequate.<br />

During handling operations, make sure that the motor shaft and tachometer<br />

shaft (if present) don’t receive any hit, in order to avoid motor damage.<br />

During all operations of lifting and handling, never movimentate motors by<br />

hand but use adequate tools. In order to avoid that motor can falls, creating<br />

danger for authorized working persons in the nearings, use one of following<br />

methods:<br />

- use lifting slings of adequate capacity;<br />

- use adequate eyebolt using the thread hole in the shaft end.<br />

Refer to the following pictures.<br />

The data specified into the catalogue are for product description purpose only and must not be interpreted as warranted characteristics in legal sense. Italgroup S.r.l. reserves the<br />

right to implement modifications without notice. All partial or total reproduction and copy without written authorization of Italgroup S.r.l. is strictly forbidden.<br />

19

<strong>ITAL</strong><strong>GROUP</strong> <strong>MOTOR</strong>S <strong>R8D</strong> SERIES TECHNICAL CATALOGUE<br />

<strong>MOTOR</strong> HANDLING AND STORAGE<br />

Storage<br />

Storing must be carefully made using adequate storing tools (for example<br />

boxes, pallets, etc...) that can guarantee that the motor is stable and cannot<br />

move without control, in order to avoid damage problems. Make sure that<br />

the weight of the motor doesn’t be substained by the motor shaft or by the<br />

tachometer shaft (if present).<br />

<strong>R8D</strong> series motors are supplied together with plastic plugs, that keep the<br />

hydraulic oil (that was used during final test in Italgroup testing workbench)<br />

inside the motor. A thin oil film is present on the internal motor parts, whereas<br />

the external parts are covered with antirust oil that prevents damage from<br />

oxidation and corrosion.<br />

Therefore the motors can be safely stored into the customer warehouse<br />

without performance losses for long periods (up to 4-6 months).<br />

The storing location must has some important characteristics:<br />

- room temperature comprised between -15°C and +55°C without fast and/or<br />

excessives temperature excursions;<br />

- low relative humidity;<br />

- absence of aggressive and corrosive medias in the motor nearings.<br />

In particular, if motor should be motionless for more than 4-6 months, it must<br />

be protected against internal rust. Proceed as follows:<br />

- fill the motor case with hydraulic oil. After that the motor case is full of oil,<br />

close it with a screw plug;<br />

- fill the motor also from inlet or outlet port. Turn the shaft by hand (the shaft<br />

must make about one revolution) and finally close the inlet and outlet ports.<br />

Please note that the plastic plugs are necessary not only to keep the hydraulic<br />

oil inside the motor, but even to avoid that dirt and other fluids (like water<br />

for example) can enter into the motor and create damage during storing or<br />

during motor start-up. Therefore make sure all drain ports, supply ports and<br />

discharge ports are closed during motor handling and storing. If plugs are<br />

missing, use plastic plugs or adequate systems in order to guarantee that<br />

the motor is well protected by dirt and other fluids.<br />

20<br />

<strong>R8D</strong> rev.01 - Jan. 2019

MAINTENANCE OPERATIONS<br />

Maintenance operations<br />

All the assembly and maintenance works must be performed when the motor<br />

is stopped and not connected to any power source, in order to avoid an accidental<br />

start-up. In addition the pressure inside the motor must be set to zero<br />

(the motor must be depressurized) before to perform maintenance operations.<br />

The motor maintenance must be performed by instructed and experienced<br />

personnel only, following carefully Italgroup advices and procedures.<br />

<strong>R8D</strong> series motors are internally lubricated by the operating fluid, if the motors<br />

are used according to the technical data reported into the <strong>R8D</strong> catalogue, they<br />

need very limited maintenance operations. In order to achieve good performances,<br />

long bearings lifetime and safe working, the working fluid must be<br />

carefully selected in function of the operating parameters (a fundamental parameter<br />

is the ambient temperature range). In case of fire resistence fluid usage<br />

, some limitation on pressure and speed can be required. Refer to hydraulic<br />

fluid recommendations section for more information. If required please contact<br />

Italgroup technical department for further information.<br />

Motor parts<br />

Motor shaft, rollers, pins, screws,<br />

distributor bush, rotating distributor,<br />

distributor joint, pistons, connecting<br />

rod, ring for rod<br />

Motor case, cylinders, motor flange,<br />

distributor body<br />

Distributor disk, piston shoes<br />

Slippers<br />

O-Rings<br />

Radial shaft seal rings<br />

Material<br />

Steel<br />

Cast iron<br />

Bronze<br />

Charged PTFE, PTFE<br />

Elastomer<br />

Elastomer / charged PTFE<br />

The data specified into the catalogue are for product description purpose only and must not be interpreted as warranted characteristics in legal sense. Italgroup S.r.l. reserves the<br />

right to implement modifications without notice. All partial or total reproduction and copy without written authorization of Italgroup S.r.l. is strictly forbidden.<br />

21

<strong>ITAL</strong><strong>GROUP</strong> <strong>MOTOR</strong>S <strong>R8D</strong> SERIES TECHNICAL CATALOGUE<br />

INSTRUCTIONS AND ADVICES<br />

Bearings<br />

The bearing life depends by different factors, like bearing type, motor<br />

speed, working pressure, external loads, duty cycle, fluid viscosity, oil<br />

cleanliness, type and temperature.<br />

Lifetime is measured by L 10<br />

which is called “theoretic lifetime”. It represents<br />

the number of cycles that 90% of identical bearings can effort at<br />

the same load without showing wear and tear.<br />

Please refer to bearing lifetime diagrams reported in the following pages<br />

to obtain the theoretical bearing lifetime. The lifetimes diagrams shown<br />

the L 50<br />

, median or average lifetime, that can be considered as 5 times<br />

L 10<br />

.<br />

Please note that the theoretical lifetime can be different from the real<br />

lifetime, especially in case of heavy duty applications with continuous<br />

work cycle.<br />

Please contact Italgroup S.r.l. for more information.<br />

Motor creep speed<br />

The hydraulic motor is able to hold the load acting as a brake (if proper<br />

valves or circuit are considered and installed), but a certain creep speed<br />

is always present: this is typical of all brands hydraulic motors.<br />

The motor creep speed depends by many factors, like operating conditions<br />

(motor displacement and type, pressure load on the shaft, oil viscosity,<br />

type and temperature)<br />

If creep speed is higher than desired value a negative brake can be<br />

considered: Italgroup can supply negative brakes that can be fitted to<br />

the hydraulic motor.<br />

Please contact Italgroup S.r.l. for more information.<br />

22<br />

<strong>R8D</strong> rev.01 - Jan. 2019

SPECIAL FEATURES<br />

Special features<br />

Marine painting<br />

If needed, special painting or primers are available in order to guarantee<br />

optimal protection against normal corrosion and marine environment corrosion.<br />

The ordering code is MP. Please contact Italgroup S.r.l. for more<br />

information.<br />

Speedy-sleeve<br />

A special inox sleeve is available upon request. In case the motor is used<br />

in aggressive medias or environments, this can be very useful in order<br />

to protect the motor shaft surface located in proximity of the motor shaft<br />

seal. This improves the shaft and seal endurance respect to wear and<br />

corrosion. The ordering code is SPSL. Please contact Italgroup S.r.l. for<br />

more information.<br />

High pressure shaft seal<br />

Standard <strong>R8D</strong> motors are supplied with high pressure shaft seals, the<br />

continuous drain pressure must be maximum 6 bar, whereas the peak<br />

drain pressure must be maximum 10 bar. In case the drain line can or<br />

must has a higher pressure, special shaft seals are available upon request.<br />

The ordering code is HPS. The drain pressure with HPS shaft seal<br />

can reach 20-25 bar continuous pressure and 30 bar peak pressure. The<br />

HPS shaft seal is bi-directional also, so it can be used for example in underwater<br />

applications. Please contact Italgroup S.r.l. for more information.<br />

Counterclockwise rotation<br />

Standard <strong>R8D</strong> motors are supplied with clockwise distributor timing. Please<br />

refer to the installation drawings of each section for more information.<br />

With ordering code CCW the motor is supplied with counterclockwise<br />

rotation timing. Contact Italgroup for more information.<br />

Standard timing<br />

CCW timing<br />

Oil inlet<br />

Oil outlet<br />

The data specified into the catalogue are for product description purpose only and must not be interpreted as warranted characteristics in legal sense. Italgroup S.r.l. reserves the<br />

right to implement modifications without notice. All partial or total reproduction and copy without written authorization of Italgroup S.r.l. is strictly forbidden.<br />

23

<strong>ITAL</strong><strong>GROUP</strong> <strong>MOTOR</strong>S <strong>R8D</strong> SERIES TECHNICAL CATALOGUE<br />

TROUBLESHOOTING<br />

Problem Possible cause Solution<br />

Excessive noises<br />

Unit overheating<br />

Anomalous drainage flow<br />

Insufficient torque<br />

Insufficient speed<br />

Output shaft cannot rotate<br />

Cavitation<br />

Mechanical vibrations<br />

Irregular pressure or flow<br />

Air bubbles in the circuit<br />

Overflow<br />

Overpressure<br />

Oil viscosity too low<br />

Undersized cooling system<br />

Working without oil in the case<br />

Worn motor internal<br />

components<br />

Motor internal seals worn<br />

Excessive pressure in the motor<br />

case<br />

Pressure relief valve set<br />

incorrectly<br />

Undersized motor displacement<br />

Pump not able to reach the<br />

design pressure<br />

Oversized motor displacement<br />

Pump not able to reach the<br />

design flow<br />

Undersized pump<br />

Excessive drain flow<br />

Seized motor flow distributor<br />

Motor internal seizure<br />

Motor internal seals worn<br />

Air in the circuit<br />

Adopt an anti-cavitation system<br />

Check and fix damaged<br />

components<br />

Check other components<br />

(pump, valves, accumulators)<br />

and check drain flow<br />

Bleed circuit<br />

Check max allowed flow<br />

Check relief valve pressure<br />

setting<br />

Choose the appropriate oil<br />

according to the temperature<br />

Improve cooling system<br />

Overhaul the unit, fill with oil<br />

before start-up<br />

Overhaul the motor<br />

Overhaul the motor<br />

Check drain port size, pressure<br />

and flow, check piping<br />

connections<br />

Check relief valve pressure<br />

setting<br />

Replace with bigger displ.<br />

motor<br />

Check pump integrity<br />

Replace with smaller displ.<br />

motor<br />

Check pump integrity<br />

Improve pump output flow<br />

Overhaul the motor<br />

Overhaul the flow distributor<br />

Overhaul the motor<br />

Check drain flow, overhaul the<br />

motor<br />

Bleed the circuit<br />

24<br />

<strong>R8D</strong> rev.01 - Jan. 2019

Problem Possible cause Solution<br />

Oil leakage<br />

Incorrecte sense of rotation<br />

Worn seals<br />

Excessive pressure in the motor<br />

case<br />

Burst motor shaft seal<br />

Pipes incorrectly connected<br />

Incorrect rotating distributor<br />

timing<br />

Replace seals<br />

Check drain port size, pressure<br />

and flow, check piping connections<br />

Check drain port size, pressure<br />

and flow, check piping connections<br />

Check pipe connections<br />

Change rotating distributor<br />

timing<br />

The data specified into the catalogue are for product description purpose only and must not be interpreted as warranted characteristics in legal sense. Italgroup S.r.l. reserves the<br />

right to implement modifications without notice. All partial or total reproduction and copy without written authorization of Italgroup S.r.l. is strictly forbidden.<br />

25

<strong>ITAL</strong><strong>GROUP</strong> <strong>MOTOR</strong>S <strong>R8D</strong> SERIES TECHNICAL CATALOGUE<br />

LENGHT 1 m = 39,3701 in MASS 1 kg = 2,2046 lb POWER 1 kW = 1,341 HP<br />

= 3,2808 ft = 1,3596 CV<br />

= 1,0936 yd FORCE 1 N = 0,102 kgf 1 HP = 0,7457 kW<br />

= 1000 mm = 0,2248 lbf = 1,0139 CV<br />

1 in = 0,0833 ft 1 kgf = 2,205 lbf<br />

= 25,4 mm = 9,806 N VOLUME 1 m 3 = 1000 l<br />

1 ft = 0,3048 m 1 lbf = 0,4536 kgf 1 l = 61,023 in 3<br />

= 0,3333 yd = 4,448 N = 0,264 galUS<br />

= 12 in 1 in 3 = 0,01639 l<br />

1 yd = 0,9144 m PRESSURE 1 bar = 14,223 psi = 16,39 cm 3<br />

= 3 ft = 0,99 atm = 0,004326<br />

galUS<br />

= 36 in = 1,02 ata 1 galUS = 3,7879 l<br />

1 km = 1000 m = 100000 Pa =231,15 in 3<br />

= 1093,6 yd = 100 kPa<br />

= 0,6214 mile = 0,1 MPa TORQUE 1 Nm = 0,102 kgm<br />

1 mile = 1,609 km 1 psi = 0,0703 bar = 0,7376 lbf ft<br />

= 1760 yd 1 kgm = 9,806 Nm<br />

FLOW 1 l/min = 0,264 gpm = 7,2325 lbf ft<br />

SPEED 1 m/s = 3,6 km/h = 1000 cc/Rev 1 lbf ft = 0,1383 kgm<br />

= 2,237 mph 1 gpm = 3,785 l/min = 1,3558 Nm<br />

= 3,2808 ft/s = 3785 cc/min<br />

1 km/h = 0,2778 m/s 1 m 3 /s = 60000 l/min<br />

= 0,6214 mph = 15852 gpm<br />

= 0,9113 ft/s<br />

1 mph = 1,609 km/h<br />

= 0,447 m/s<br />

= 1,467 ft/s<br />

1 ft/s = 0,3048 m/s<br />

= 1,0973 km/h<br />

= 0,6818 mph<br />

26<br />

<strong>R8D</strong> rev.01 - Jan. 2019

<strong>R8D</strong> H2<br />

<strong>R8D</strong> 300 H2 Pag. 28 - 29<br />

<strong>R8D</strong> 300/GM2 H2 Pag. 30 - 31<br />

<strong>R8D</strong> 300/S H2 Pag. 32 - 33<br />

<strong>R8D</strong> H2 - PERFORMANCE CURVES Pag. 34 - 35<br />

<strong>R8D</strong> H2 - ORDERING CODE Pag. 36<br />

The data specified into the catalogue are for product description purpose only and must not be interpreted as warranted characteristics in legal sense. Italgroup S.r.l. reserves the<br />

right to implement modifications without notice. All partial or total reproduction and copy without written authorization of Italgroup S.r.l. is strictly forbidden.<br />

27

<strong>ITAL</strong><strong>GROUP</strong> <strong>MOTOR</strong>S <strong>R8D</strong> SERIES TECHNICAL CATALOGUE<br />

<strong>R8D</strong> 300 H2<br />

20<br />

14<br />

9<br />

164<br />

DRAIN PORT<br />

3/8" BSP<br />

N°2 PORTS<br />

1" BSP<br />

130<br />

69<br />

20<br />

~82<br />

190 -0,05<br />

-0,15<br />

86<br />

341<br />

D40 (*)<br />

77<br />

41<br />

141<br />

MTG FACE<br />

N°5 MTG HOLES<br />

12,5 ON A 210 P.C.D.<br />

DRAIN PORT<br />

3/8" BSP<br />

68<br />

Ø210<br />

TECHNICAL DATA<br />

300<br />

DISPLACEMENT [cc] 314<br />

SPECIFIC TORQUE [Nm/bar] 5<br />

MAX. CONT. PRESSURE [bar] 270<br />

HYDROSTATIC TEST PRES-<br />

SURE<br />

[bar] 420<br />

MAX. CONT. SPEED [rpm] 900<br />

PEAK SPEED (***) [rpm] 1100<br />

MAX. CONT. POWER (****) [kW] 45<br />

MAX. POWER [kW] 66<br />

MAX. CASE PRESSURE [bar] 6<br />

DRY WEIGHT [kg] 42<br />

TEMPERATURE RANGE (**) [°C] -30÷70<br />

- (*) The standard distributor (D40) is shown. Please refer to distributors section (pag. 174-175) for differents distributor interfaces.<br />

- (**) Please refer to the hydraulic fluid recommendations (pag. 10-11).<br />

- (***) Do not exceed maximum power (see pag. 13).<br />

- (****) For motor operation with a continuous duty cycle at maximum continuous power the flushing is usually required. For<br />

more information please contact our technical department.<br />

28<br />

<strong>R8D</strong> rev.01 - Jan. 2019

SHAFTS<br />

MOUNTING FACE<br />

MOUNTING FACE<br />

MOUNTING FACE<br />

MOUNTING FACE<br />

A0<br />

79<br />

79<br />

79 79 79<br />

57<br />

57<br />

57 57 57<br />

38<br />

38<br />

38 38 38<br />

M12x30<br />

M12x30<br />

32 UNI 221<br />

M12x30<br />

32 UNI 221<br />

UNI<br />

32 UNI<br />

-<br />

221<br />

UNI M12x30 8953 8x32x38<br />

UNI<br />

DIN DIN ISO 32 8953<br />

ISO UNI 14<br />

- 8x32x38<br />

14 221 8x32x38 - DIN 32 UNI 221<br />

UNI ISO 8953 14 - - 8x32x38 8x32x38<br />

UNI 8953 - 8x32x38<br />

DIN ISO 14 - 8x32x38<br />

DIN ISO 14 - 8x32x38<br />

MOUNTING FACE<br />

MOUNTING FACE<br />

MOUNTING FACE<br />

MOUNTING FACE<br />

A1<br />

79<br />

79<br />

79 79 79<br />

57<br />

57<br />

57 57 57<br />

38<br />

38<br />

38 38 38<br />

M12x30<br />

M12x30<br />

W40x3x12-8e<br />

M12x30<br />

W40x3x12-8e M12x30<br />

DIN DIN 5480<br />

W40x3x12-8e<br />

DIN 5480<br />

W40x3x12-8e<br />

DIN 5480<br />

DIN 5480<br />

Available spline billet:<br />

SB2<br />

Available spline billet:<br />

SB22<br />

41 41<br />

41<br />

10<br />

10 10<br />

41<br />

41<br />

MOUNTING FACE<br />

MOUNTING FACE<br />

10<br />

10<br />

A2<br />

MOUNTING FACE<br />

MOUNTING FACE<br />

45<br />

45 45<br />

45<br />

45 6 6<br />

57 57<br />

57 57 79 57<br />

79<br />

79 79 79<br />

M12x30<br />

M12x30<br />

6<br />

6<br />

M12x30<br />

M12x30<br />

∅38±0,01<br />

∅38±0,01<br />

∅38±0,01<br />

∅38±0,01<br />

8 8<br />

MOUNTING FACE<br />

MOUNTING FACE<br />

A3<br />

MOUNTING FACE<br />

MOUNTING FACE<br />

N40x3x12-9H<br />

N40x3x12-9H<br />

DIN DIN 5480<br />

N40x3x12-9H<br />

DIN 5480<br />

∅55 ∅55 N40x3x12-9H<br />

∅55 DIN 5480<br />

DIN 5480<br />

∅55<br />

∅55<br />

8<br />

8 36<br />

36<br />

36 36 36 48<br />

48<br />

48 48 48<br />

MOUNTING FACE<br />

MOUNTING FACE<br />

A31<br />

MOUNTING FACE<br />

MOUNTING FACE<br />

8<br />

8 8 8 36<br />

36<br />

36 36 36 48<br />

48<br />

48 48 48<br />

36 36 UNI UNI 220 220<br />

36 UNI 220<br />

∅55 ∅55<br />

36 ∅55 UNI 220<br />

36 UNI 220<br />

∅55<br />

∅55<br />

Available spline bar:<br />

B8076<br />

Available spline bar:<br />

B8078<br />

The data specified into the catalogue are for product description purpose only and must not be interpreted as warranted characteristics in legal sense. Italgroup S.r.l. reserves the<br />

right to implement modifications without notice. All partial or total reproduction and copy without written authorization of Italgroup S.r.l. is strictly forbidden.<br />

29

<strong>ITAL</strong><strong>GROUP</strong> <strong>MOTOR</strong>S <strong>R8D</strong> SERIES TECHNICAL CATALOGUE<br />

<strong>R8D</strong> H2/GM2<br />

18<br />

4<br />

N°5 MTG HOLES<br />

12,5 ON A 250 P.C.D.<br />

164<br />

DRAIN PORT<br />

3/8" BSP<br />

N°2 PORTS<br />

1" BSP<br />

130<br />

69<br />

150 -0,05<br />

-0,15<br />

250<br />

280<br />

86<br />

341<br />

D40 (*)<br />

41<br />

77 159<br />

MTG FACE<br />

5<br />

DRAIN PORT<br />

3/8" BSP<br />

68<br />

TECHNICAL DATA<br />

300<br />

DISPLACEMENT [cc] 314<br />

SPECIFIC TORQUE [Nm/bar] 5<br />

MAX. CONT. PRESSURE [bar] 270<br />

HYDROSTATIC TEST PRES-<br />

SURE<br />

[bar] 420<br />

MAX. CONT. SPEED [rpm] 900<br />

PEAK SPEED (***) [rpm] 1100<br />

MAX. CONT. POWER (****) [kW] 45<br />

MAX. POWER [kW] 66<br />

MAX. CASE PRESSURE [bar] 6<br />

DRY WEIGHT [kg] 42<br />

TEMPERATURE RANGE (**) [°C] -30÷70<br />

- (*) The standard distributor (D40) is shown. Please refer to distributors section (pag. 174-175) for differents distributor interfaces.<br />

- (**) Please refer to the hydraulic fluid recommendations (pag. 10-11).<br />

- (***) Do not exceed maximum power (see pag. 13).<br />

- (****) For motor operation with a continuous duty cycle at maximum continuous power the flushing is usually required. For<br />

more information please contact our technical department.<br />

30<br />

<strong>R8D</strong> rev.01 - Jan. 2019

SHAFTS<br />

MOUNTING FACE<br />

A0<br />

72<br />

72<br />

72<br />

67<br />

67<br />

67<br />

M16x32<br />

48<br />

48<br />

48<br />

M16x32<br />

36 UNI 220<br />

UNI M16x32<br />

8953 - 8x36x40<br />

36 UNI 220<br />

DIN ISO 14 - 8x36x40<br />

UNI 36 8953 UNI - 8x36x40<br />

220<br />

DIN UNI ISO 8953 14 - - 8x36x40<br />

8x36x40<br />

DIN ISO 14 - 8x36x40<br />

MOUNTING FACE<br />

61<br />

61<br />

61<br />

57<br />

57<br />

57<br />

A1<br />

M12x30<br />

38<br />

38<br />

38<br />

M12x30<br />

W40x3x12-8e<br />

M12x30<br />

DIN 5480<br />

W40x3x12-8e<br />

W40x3x12-8e<br />

DIN 5480<br />

DIN 5480<br />

Available spline billet:<br />

SB3 Available spline billet: SB22<br />

A2<br />

A3<br />

A31<br />

16<br />

MOUNTING FACE<br />

55<br />

55<br />

55 5<br />

M20x40<br />

54<br />

MOUNTING FACE<br />

MOUNTING FACE<br />

MOUNTING FACE<br />

MOUNTING FACE<br />

16<br />

16<br />

MOUNTING FACE<br />

MOUNTING FACE<br />

5<br />

5<br />

M20x40<br />

∅50 m6<br />

M20x40<br />

∅50 m6<br />

∅50 m6<br />

MOUNTING FACE<br />

N40x3x12-9H<br />

MOUNTING FACE<br />

DIN<br />

MOUNTING 5480<br />

FACE<br />

N40x3x12-9H<br />

N40x3x12-9H<br />

∅55 DIN 5480<br />

∅55<br />

DIN 5480<br />

∅55<br />

MOUNTING FACE<br />

MOUNTING FACE<br />

36 MOUNTING UNI 220 FACE<br />

36 ∅55 UNI 220<br />

36 ∅55 UNI 220<br />

∅55<br />

54<br />

54<br />

66<br />

66<br />

66<br />

72<br />

72<br />

72<br />

8<br />

8<br />

8 18<br />

18<br />

18<br />

48<br />

48<br />

48<br />

8<br />

18<br />

18<br />

18<br />

8<br />

8<br />

48<br />

48<br />

48<br />

Available spline bar:<br />

B8076<br />

Available spline bar:<br />

B8078<br />

The data specified into the catalogue are for product description purpose only and must not be interpreted as warranted characteristics in legal sense. Italgroup S.r.l. reserves the<br />

right to implement modifications without notice. All partial or total reproduction and copy without written authorization of Italgroup S.r.l. is strictly forbidden.<br />

31

<strong>ITAL</strong><strong>GROUP</strong> <strong>MOTOR</strong>S <strong>R8D</strong> SERIES TECHNICAL CATALOGUE<br />

<strong>R8D</strong> H2/S<br />

18<br />

6<br />

N°5 MTG HOLES<br />

12,5 ON A 195 P.C.D.<br />

164<br />

DRAIN PORT<br />

3/8" BSP<br />

N°2 PORTS<br />

1" BSP<br />

130<br />

69<br />

150 -0,05<br />

-0,15<br />

19<br />

195<br />

280<br />

86<br />

341<br />

D40 (*)<br />

41<br />

77 159<br />

MTG FACE<br />

5<br />

DRAIN PORT<br />

3/8" BSP<br />

68<br />

TECHNICAL DATA<br />

300<br />

DISPLACEMENT [cc] 314<br />

SPECIFIC TORQUE [Nm/bar] 5<br />

MAX. CONT. PRESSURE [bar] 270<br />

HYDROSTATIC TEST PRES-<br />

SURE<br />

[bar] 420<br />

MAX. CONT. SPEED [rpm] 900<br />

PEAK SPEED (***) [rpm] 1100<br />

MAX. CONT. POWER (****) [kW] 45<br />

MAX. POWER [kW] 66<br />

MAX. CASE PRESSURE [bar] 6<br />

DRY WEIGHT [kg] 42<br />

TEMPERATURE RANGE (**) [°C] -30÷70<br />

- (*) The standard distributor (D40) is shown. Please refer to distributors section (pag. 174-175) for differents distributor interfaces.<br />

- (**) Please refer to the hydraulic fluid recommendations (pag. 10-11).<br />

- (***) Do not exceed maximum power (see pag. 13).<br />

- (****) For motor operation with a continuous duty cycle at maximum continuous power the flushing is usually required. For<br />

more information please contact our technical department.<br />

32<br />

<strong>R8D</strong> rev.01 - Jan. 2019

SHAFTS<br />

MOUNTING FACE<br />

A0<br />

72<br />

72<br />

72<br />

67<br />

67<br />

67<br />

M16x32<br />

48<br />

48<br />

48<br />

M16x32<br />

36 UNI 220<br />

UNI M16x32<br />

8953 - 8x36x40<br />

36 UNI 220<br />

DIN ISO 14 - 8x36x40<br />

UNI 36 8953 UNI - 8x36x40<br />

220<br />

DIN UNI ISO 8953 14 - - 8x36x40<br />

8x36x40<br />

DIN ISO 14 - 8x36x40<br />

MOUNTING FACE<br />

61<br />

61<br />

61<br />

57<br />

57<br />

57<br />

A1<br />

M12x30<br />

38<br />

38<br />

38<br />

M12x30<br />

W40x3x12-8e<br />

M12x30<br />

DIN 5480<br />

W40x3x12-8e<br />

W40x3x12-8e<br />

DIN 5480<br />

DIN 5480<br />

Available spline billet:<br />

SB3 Available spline billet: SB22<br />

A2<br />

A3<br />

A31<br />

16<br />

MOUNTING FACE<br />

55<br />

55<br />

55 5<br />

M20x40<br />

54<br />

MOUNTING FACE<br />

MOUNTING FACE<br />

MOUNTING FACE<br />

MOUNTING FACE<br />

16<br />

16<br />

MOUNTING FACE<br />

MOUNTING FACE<br />

5<br />

5<br />

M20x40<br />

∅50 m6<br />

M20x40<br />

∅50 m6<br />

∅50 m6<br />

MOUNTING FACE<br />

N40x3x12-9H<br />

MOUNTING FACE<br />

DIN<br />

MOUNTING 5480<br />

FACE<br />

N40x3x12-9H<br />

N40x3x12-9H<br />

∅55 DIN 5480<br />

∅55<br />

DIN 5480<br />

∅55<br />

MOUNTING FACE<br />

MOUNTING FACE<br />

36 MOUNTING UNI 220 FACE<br />

36 ∅55 UNI 220<br />

36 ∅55 UNI 220<br />

∅55<br />

54<br />

54<br />

66<br />

66<br />

66<br />

72<br />

72<br />

72<br />

8<br />

8<br />

8 18<br />

18<br />

18<br />

48<br />

48<br />

48<br />

8<br />

18<br />

18<br />

18<br />

8<br />

8<br />

48<br />

48<br />

48<br />

Available spline bar:<br />

B8076<br />

Available spline bar:<br />

B8078<br />

The data specified into the catalogue are for product description purpose only and must not be interpreted as warranted characteristics in legal sense. Italgroup S.r.l. reserves the<br />

right to implement modifications without notice. All partial or total reproduction and copy without written authorization of Italgroup S.r.l. is strictly forbidden.<br />

33

<strong>ITAL</strong><strong>GROUP</strong> <strong>MOTOR</strong>S <strong>R8D</strong> SERIES TECHNICAL CATALOGUE<br />

<strong>R8D</strong> H2 - PERFORMANCE CURVES<br />

<strong>R8D</strong> 300 H2<br />

350 bar<br />

300 bar<br />

270 bar<br />

180 bar<br />

120 bar<br />

60 bar<br />

Continuous operation<br />

Continuous operation with flushing or intermittent operation<br />

(see below for intermittent operation)<br />

Intermittent operation: permitted for a 15% of<br />

duty cycle, for 3 minutes maximum period<br />

Peak operation: permitted for very short<br />

periods (3-5 seconds every 10-15 minutes)<br />

The above diagrams are referring to the hydraulic motor working<br />

with a fluid in ideal conditions (viscosity at 40 cSt). In<br />

case the working temperature increases and viscosity reach<br />

values under the recommended values (see hydraulic fluid<br />

recommendations) flushing must be performed or ISO oil<br />

grade must be changed. The working temperature must not<br />

overcome 70 °C.<br />

34<br />

<strong>R8D</strong> rev.01 - Jan. 2019

CREEP SPEED - VOLUMETRIC EFFICIENCY<br />

50 100<br />

300 600<br />

300<br />

15<br />

10<br />

5<br />

creep speed [rpm]<br />

25<br />

10 rpm<br />

200<br />

0 1 2 3<br />

external leakage [l/min]<br />

0<br />

60 70 80 90 100<br />

volumetric efficiency [%]<br />

0 50<br />

100 150 200 250<br />

pressure [bar]<br />

Reference viscosity: 40 cSt<br />

Example:<br />

We suppose (300 cc): p=200 [bar], we obtain: external leakage 2,9 [l/min], shaft creep speed 12,7 [rpm].<br />

If we suppose (300 cc): p=200 [bar] and n=300 [rpm] we obtain a volumetric efficiency of 96%;<br />

BEARING LIFE<br />

n=25<br />

n=50<br />

EX 2<br />

n=100<br />

n=200<br />

n=300<br />

n=500<br />

n=1000<br />

EX 1<br />

120 bar<br />

180 bar<br />

250 bar<br />

60 bar<br />

L50h<br />

5 4 3 200000<br />

9 8 7 6 5 4 3 2 10 4<br />

10 5<br />

5000<br />

5 kN<br />

a=150 mm<br />

a=100 mm<br />

a=75 mm<br />

F r<br />

F r<br />

10 kN<br />

Shaft stress limit<br />

Fr=radial load<br />

a=distance of radial load from mounting face<br />

n=shaft speed [rpm]<br />

15 kN<br />

a=50 mm<br />

a<br />

20 kN<br />

Reference viscosity: 40 cSt<br />

Example:<br />

We suppose (EX1): p=120 [bar], n=50 [rpm]; we obtain an average lifetime of 200000 [h].<br />

If we suppose (EX2): F r<br />

=10 [kN], a=50 [mm], n=50 [rpm] and p=250 [bar] we obtain an average lifetime<br />

of 12500 [h].<br />

The data specified into the catalogue are for product description purpose only and must not be interpreted as warranted characteristics in legal sense. Italgroup S.r.l. reserves the<br />

right to implement modifications without notice. All partial or total reproduction and copy without written authorization of Italgroup S.r.l. is strictly forbidden.<br />

35

<strong>ITAL</strong><strong>GROUP</strong> <strong>MOTOR</strong>S <strong>R8D</strong> SERIES TECHNICAL CATALOGUE<br />

<strong>R8D</strong> H2 - ORDERING CODE<br />

<strong>R8D</strong> - - - - H2 - - - - - - - - SB -<br />

TACHOMETER<br />

DISPLACEMENT<br />

300<br />

INTERCHANGEABILITY<br />

/GM2<br />

SERIE<br />

/S<br />

H2<br />

SHAFT<br />

A0<br />

A1<br />

A2<br />

A3<br />

A31<br />

DISTRIBUTOR<br />

TA<br />

TB<br />

TT1<br />

TQ1<br />

EST<br />

EST30<br />

EST31<br />

EST32<br />

EST33<br />

See pag. 177-180<br />

SPECIAL<br />

FEATURES<br />

MP<br />

SPSL<br />

HPS<br />

CCW<br />

See pag. 23<br />

Z - -<br />

Italgroup<br />

internal code<br />

SPLINE<br />

BILLET<br />

SB2<br />

SB3<br />

SB22<br />

See pag. 181-185<br />

D31B<br />

D31BJ<br />

D36B<br />

D36BJ<br />

D310B<br />

D310BJ<br />

D40<br />

D40J<br />

D47<br />

D47J<br />

D416<br />

D416J<br />

See pag. 174-175<br />

EXAMPLES:<br />

<strong>R8D</strong> 300/GM2 H2 A1 D40<br />

<strong>R8D</strong> 300 H2 A2 D310B<br />

<strong>R8D</strong> 300/GM2 H2 A0 D47 CCW<br />

36<br />

<strong>R8D</strong> rev.01 - Jan. 2019

<strong>R8D</strong> H3<br />

<strong>R8D</strong> H3 Pag. 38 - 39<br />

<strong>R8D</strong> H3/C Pag. 40 - 41<br />

<strong>R8D</strong> H3/RM Pag. 42 - 43<br />

<strong>R8D</strong> H3/H4C Pag. 44 - 45<br />

<strong>R8D</strong> H3 - PERFORMANCE CURVES Pag. 46 - 49<br />

<strong>R8D</strong> H3 - ORDERING CODE Pag. 50<br />

The data specified into the catalogue are for product description purpose only and must not be interpreted as warranted characteristics in legal sense. Italgroup S.r.l. reserves the<br />

right to implement modifications without notice. All partial or total reproduction and copy without written authorization of Italgroup S.r.l. is strictly forbidden.<br />

37

<strong>ITAL</strong><strong>GROUP</strong> <strong>MOTOR</strong>S <strong>R8D</strong> SERIES TECHNICAL CATALOGUE<br />

<strong>R8D</strong> H3<br />

19<br />

14<br />

190<br />

DRAIN PORT<br />

1/2" BSP<br />

N°2 PORTS<br />

1" BSP<br />

130<br />

69<br />

24<br />

150<br />

- 0,05<br />

- 0,15<br />

230<br />

95<br />

386<br />

D40 (*)<br />

41<br />

77 165<br />

MTG FACE<br />

10<br />

N°5 MTG. HOLES<br />

15 ON A 254 P.C.D.<br />

DRAIN PORT<br />

1/2" BSP<br />

68<br />

254<br />

350 400 450 500 600 700<br />

DISPLACEMENT [cc] 342 398 452 492 594 707<br />

SPECIFIC TORQUE [Nm/bar] 5.4 6.3 7.2 7.8 9.5 11.2<br />

MAX. CONT. PRESSURE [bar] 270 270 270 270 270 170<br />

HYDROSTATIC TEST PRES-<br />

SURE<br />

[bar] 420 420 420 420 420 420<br />

MAX. CONT. SPEED [rpm] 850 750 650 600 500 440<br />

PEAK SPEED (***) [rpm] 950 860 760 690 570 500<br />

MAX. CONT. POWER (****) [kW] 85 85 85 85 85 78<br />

MAX. POWER [kW] 130 130 130 130 130 118<br />

MAX. CASE PRESSURE [bar] 6 6 6 6 6 6<br />

DRY WEIGHT [kg] 68 68 68 68 68 68<br />

TEMPERATURE RANGE (**) [°C] -30÷70 -30÷70 -30÷70 -30÷70 -30÷70 -30÷70<br />

TECHNICAL DATA<br />

- (*) The standard distributor (D40) is shown. Please refer to distributors section (pag. 174-175) for differents distributor interfaces.<br />

- (**) Please refer to the hydraulic fluid recommendations (pag. 10-11).<br />

- (***) Do not exceed maximum power (see pag. 13).<br />

- (****) For motor operation with a continuous duty cycle at maximum continuous power the flushing is usually required. For<br />

more information please contact our technical department.<br />

38<br />

<strong>R8D</strong> rev.01 - Jan. 2019

SHAFTS<br />

MOUNTING FACE<br />

MOUNTING FACE<br />

90<br />

MOUNTING FACE<br />

63<br />

43<br />

63<br />

M14x30<br />

43<br />

36 UNI 221<br />

UNI 8953 8x36x42<br />

DIN ISO 14 - 8x36x42<br />

A0<br />

M14x30<br />

63<br />

43<br />

36 UNI 221<br />

UNI M14x30 8953 8x36x42<br />

DIN ISO 14 - 8x36x42<br />

36 UNI 221<br />

UNI 8953 8x36x42<br />

DIN ISO 14 - 8x36x42<br />

45<br />

45<br />

12<br />

12<br />

45<br />

MOUNTING FACE<br />

MOUNTING FACE<br />

12<br />

MOUNTING FACE<br />

50<br />

63<br />

90<br />

50<br />

6.5<br />

A2<br />

M14x30<br />

50<br />

6.5<br />

∅42±0,01<br />

M14x30<br />

∅42±0,01<br />

6.5<br />

M14x30<br />

∅42±0,01<br />

90<br />

90<br />

Available spline billet:<br />

SB3<br />

63<br />

90<br />

63<br />

90<br />

MOUNTING FACE<br />

MOUNTING FACE<br />

A3<br />

MOUNTING FACE<br />

36 UNI 220<br />

36 UNI 220<br />

∅60<br />

∅60<br />