p/Cover Story/Sep - Roof & Facade

p/Cover Story/Sep - Roof & Facade

p/Cover Story/Sep - Roof & Facade

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

&F Asia<br />

<strong>Roof</strong> acade<br />

Contents<br />

<strong>Sep</strong>tember 2004<br />

<strong>Cover</strong> <strong>Story</strong> ................................................. 1<br />

Feature: Translucent & Transparent<br />

Materials ..................................................... 4<br />

Products & Services: Translucent &<br />

Transparent Materials • Solar Control ... 6<br />

Products & Services: UPVC Windows<br />

& Doors ................................................... 13<br />

News & Events ........................................15<br />

Aincreased<br />

airport capacity. This has<br />

SEPTEMBER 2004<br />

Volume 1 Number 7 MITA (P) 295/11/2003<br />

Glass and Metal Design<br />

for New Air Transport Hub<br />

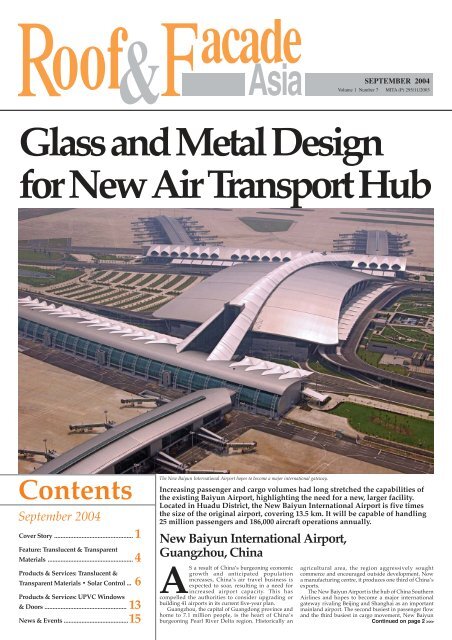

The New Baiyun International Airport hopes to become a major international gateway.<br />

Increasing passenger and cargo volumes had long stretched the capabilities of<br />

the existing Baiyun Airport, highlighting the need for a new, larger facility.<br />

Located in Huadu District, the New Baiyun International Airport is five times<br />

the size of the original airport, covering 13.5 km. It will be capable of handling<br />

25 million passengers and 186,000 aircraft operations annually.<br />

New Baiyun International Airport,<br />

Guangzhou, China<br />

S a result of China’s burgeoning economic<br />

growth and anticipated population<br />

increases, China’s air travel business is<br />

expected to soar, resulting in a need for<br />

compelled the authorities to consider upgrading or<br />

building 41 airports in its current five-year plan.<br />

Guangzhou, the capital of Guangdong province and<br />

home to 7.1 million people, is the heart of China’s<br />

burgeoning Pearl River Delta region. Historically an<br />

agricultural area, the region aggressively sought<br />

commerce and encouraged outside development. Now<br />

a manufacturing centre, it produces one third of China’s<br />

exports.<br />

The New Baiyun Airport is the hub of China Southern<br />

Airlines and hopes to become a major international<br />

gateway rivaling Beijing and Shanghai as an important<br />

mainland airport. The second busiest in passenger flow<br />

and the third busiest in cargo movement, New Baiyun<br />

Continued on page 2 >>>

<strong>Roof</strong>&<strong>Facade</strong> Asia <strong>Cover</strong> <strong>Story</strong>: Glass & Metal Design for New Air Transport Hub<br />

>>> Continued from page 1<br />

Airport will compete with five regional and international airports, including Hong Kong and Macao.<br />

It will undoubtedly continue to play an important role in regional economic development and in the<br />

future of the People’s Republic of China.<br />

The Civil Aviation Administration of China and the China State Development and Planning<br />

Commission approved the project in the 1990s.<br />

Designed by Parsons Corp, together with subcontractor URS Greiner Corp, both of the US, and<br />

Chinese design institutes such as Guangdong Provincial Architectural Design Institute, the New Baiyun<br />

International Airport will be able to accommodate the world’s largest planes.<br />

The Parsons team began designing the New Baiyun International Airport in 1999, and completed<br />

the design phase in three years, working predominantly in the US, while coordinating construction<br />

documents with local Chinese architectural firms such as the Guangdong Provincial Architectural<br />

Design Institute. Phase I construction involved more than 10,000 workers at the height of the<br />

endeavour.<br />

Phase I design included the main terminal, the east-west connection building, four concourses,<br />

landscaped surface parking, structured parking, an airport hotel, and an air traffic control tower - the<br />

tallest in the country. Phase I also included two runways, aircraft maintenance and air cargo facilities,<br />

nearly 65 aircraft hardstands (192 aircraft stands will be completed by 2010), vehicle parking, and a<br />

new highway and rail system serving the airport. Two terminal area loop roadway systems will facilitate<br />

landside vehicle traffic flow and reduce congestion. Located under the terminal will be a metro rail<br />

station for travel to downtown Guangzhou.<br />

When fully operational, the airport will house an international-standard convention centre where<br />

a visitor can get off a plane, check into a quality hotel, experience fine dining and shopping, and<br />

attend a conference, all without leaving the airport. With 200,000 sq m of commercial area set aside for<br />

shopping, a hotel with up to 800 rooms, the convention centre, and exhibition halls, the airport can<br />

generate substantial additional revenue and provide more than 10,000 local jobs.<br />

Work is now progressing on Phase II, which involves middle- and long- term planning and design<br />

of the terminal. Phase II will include an additional runway and expansion of the terminal, increasing<br />

the annual passenger capacity from 25 million to 80 million, with 360,000 aircraft operations. Phase III<br />

will involve another central ticketing terminal and 50 additional gates.<br />

Architectural Award<br />

The structural design and architectural innovation brought attention and acclaim to Guangzhou well<br />

before the New Baiyun Airport’s official opening. The airport’s airy glass and metal architectural<br />

design has attracted much attention. The project gained recognition with the American Architecture<br />

Honor Award in Year 2000. RnF<br />

PROJECT DATA<br />

Client<br />

Guangzhou Baiyun International Airport Company Ltd<br />

Project Approver<br />

Civil Aviation Administration of China (CAAC)<br />

Architect<br />

Parsons Corporation and URS Greiner Corp<br />

Guangdong Provincial Architectural Design Institute<br />

Project Duration<br />

Phase I – 1999 to 2004<br />

Project Cost<br />

US$ 520 million<br />

(Source of information for the text: Parsons Project of The Month – July 2004)<br />

2 <strong>Roof</strong> & <strong>Facade</strong> Asia • <strong>Sep</strong>tember 2004<br />

A new highway system serves the airport.<br />

KALZIP system used for the airport roof<br />

More than 150,000 sq m of KALZIP from Corus have been used for the roof of the New Baiyun International Airport. KALZIP has been favoured for<br />

application in airport projects worldwide where the microclimate is very aggressive. This is because the protective aluminium roofing system is durable,<br />

Xfdlffjdlfjdlfjsdlfjsdlfjsdfjdsfjksd<br />

corrosion-resistant, maintenance-free, capable of withstanding high wind loads, and configurable so as to provide good acoustic insulation.<br />

The airport will be capable of handling 25 million passengers annually.<br />

Enquiry No: 09/101

<strong>Cover</strong> <strong>Story</strong>: Glass & Metal Design for New Air Transport Hub<br />

<strong>Roof</strong>&<strong>Facade</strong> Asia<br />

Laminated glass with new solar interlayer<br />

THE New Baiyun International Airport incorporates laminated glass made<br />

with Solutia’s new range of advanced solar protection interlayers from the<br />

Vanceva brand.The improved solar performance of this latest generation<br />

Vanceva interlayer comes from the special infra-red absorber which Solutia<br />

has incorporated in this product. This cuts the incoming heat by selectively<br />

absorbing energy in the infra-red range while allowing the visible light to pass<br />

through.<br />

This new Vanceva interlayer offers good solar protection to occupants, as<br />

well as a host of additional benefits, including energy efficiency, occupant comfort,<br />

noise control, UV protection, and safety and security.<br />

Energy efficiency<br />

Designing with the new Vanceva interlayer enables solar heat to be kept out of<br />

a building while maintaining visible light transmission, thus reducing cooling<br />

costs.<br />

Occupant comfort<br />

With Vanceva solar interlayer, the glare of the sun can be controlled while still<br />

allowing natural light for a pleasant and productive environment.<br />

Noise control<br />

Laminated glass made with Vanceva reduces sound transmission by reducing<br />

the coincidence dip in the 1000 Hz to 2000 Hz range common to all glass products,<br />

thus improving the acoustic performance of the glass.<br />

Safety and security<br />

When subjected to impact, glass made with Vanceva will tend to absorb the<br />

force of the impact. If the glass should break, the pieces will remain adhered to<br />

the interlayer, reducing the risk of injury and offering intrusion resistance.<br />

UV protection<br />

Laminated glass made with Vanceva is expected to block more than 99% of UV<br />

radiation from the sun, thereby reducing the fading of interior furnishings,<br />

carpets and curtains.<br />

Additionally, Vanceva interlayers are non-metallic and will not corrode.<br />

Vanceva interlayers for advanced solar protection are available with<br />

four colour options - high visible transmission clear, high visible transmission<br />

green, medium visible transmission blue, and medium visible transmission<br />

grey. Approximately 20,000 sq m of laminated glass incorporating<br />

the high visible transmission green interlayer from this new Vanceva range<br />

were used in the New Baiyun International Airport project.<br />

Vanceva interlayers with enhanced solar control are best used in<br />

combination with body-tinted glass and pyrolitic or hardcoat Low E<br />

coatings, for a greater variety of designs, good visible light transmittance,<br />

effective solar control and all the traditional benefits of laminated glass.<br />

The Vanceva brand offers other advanced solutions such as aesthetics,<br />

acoustics, high security, besides advanced solar performance. RnF<br />

New Baiyun International Airport: Laminated glass with Vanceva<br />

solar interlayer contributes also to the aesthetics of the design.<br />

Enquiry No: 09/102<br />

New Baiyun International Airport: Laminated glass with Vanceva solar interlayer ensures good visible light<br />

transmittance, effective solar control, noise control, and safety and security.<br />

<strong>Roof</strong> & <strong>Facade</strong> Asia • <strong>Sep</strong>tember 2004 3

<strong>Roof</strong>&<strong>Facade</strong> Asia Feature: Translucent & Transparent Materials<br />

ETFE in Membrane Constructions<br />

– Important aspects of ETFE<br />

cushion structures<br />

Mr Dieter Linke, covertex GmbH / Engineering + Design GbR, Germany, highlighted the<br />

potential for the use of ETFE (ethyl tetra fluoro ethylene) cladding in the building industry, in<br />

his presentation at FLUOROPLAST 2004 World Congress which addressed the theme<br />

‘Fluoropolymers in Architecture - Construction – Design – Engineering’. The event, held on 28<br />

and 29 April 2004 in Zurich, Switzerland, was organised by Maack Business Services of Zurich.<br />

(The next FLUOROPLAST World Congress will be held in Zurich from 14 to 15 March 2006).<br />

Introduction<br />

Traditional architectural membranes are coated fabrics.<br />

Wind and snow loads are carried by the fabric.<br />

The coating protects the fabric against environmental<br />

impacts and it allows for the weld assembly of<br />

the panels.<br />

These membranes with PE-fabric and PVC<br />

coating or glass fibres with PVC coating are light<br />

and very strong – but never transparent.<br />

Typical characteristics of ETFE are its<br />

transparency (also combined with printing), natural<br />

light transmittance for visible light and UV-rays, its<br />

low weight and the possibility to build extended and<br />

variable curved surfaces in one piece. These<br />

characteristics make it very interesting for<br />

architectural purposes.<br />

But as ETFE membranes in roofing and cladding<br />

are not reinforced, they have to carry the loads<br />

without fabric. Thus, ETFE membranes have only a<br />

fractional amount of tensile strength, compared to<br />

coated fabric materials.<br />

It is obvious that the supporting structure and<br />

the detailing for the ETFE attachment must take this<br />

fact into account. A good way to do so, is to use ETFE<br />

in claddings as air supported cushions.<br />

It is a great challenge to merge the architect’s<br />

intentions with the special needs of ETFE<br />

structures, in order to achieve a good, durable and<br />

economic building.<br />

But to do so, knowledge about the less obvious,<br />

4 <strong>Roof</strong> & <strong>Facade</strong> Asia • <strong>Sep</strong>tember 2004<br />

though very important technical aspects relating to<br />

the use of ETFE as a structural element in buildings,<br />

is required, too. As building with ETFE has very<br />

little history, principals, architects, and engineers<br />

usually are not aware of the sometimes very rigid,<br />

boundary conditions.<br />

Depending on the type of supporting structure<br />

and the physical needs of the cladding, like thermal<br />

insulation, shading, and internal humidity, two<br />

main design groups can be identified - ETFE<br />

cushions and mechanically prestressed ETFE in a<br />

single layer.<br />

First, important aspects about ETFE cushions will<br />

be highlighted. Against this background, the special<br />

design features of the world’s largest ETFE cushion<br />

project, Allianz Arena Soccer Stadium, Munich, will<br />

be explained, and towards the end, the prospects<br />

with single layer ETFE constructions, will be<br />

discussed.<br />

Typical configuration of ETFE cushions<br />

ETFE cushions basically consist of one inner and one<br />

outer foil. Both are stabilised by automatically<br />

controlled, moderate, overpressure of the air<br />

trapped between them. This pressure is retained by<br />

fans. The layers are usually welded together along<br />

the edges and attached to the support structure with<br />

special aluminium extrusions.<br />

Static mode of operation<br />

Inward-aimed external loads (wind pressure, snow),<br />

are led to the inner foil by the internal overpressure.<br />

It carries the load, hammock-like.<br />

Outward-aimed external loads (wind suction) are<br />

carried by the outer layer in similar manner. Internal<br />

pressure and external wind suction add up to a<br />

Allianz Arena Soccer Stadium, Munich, Germany: The world’s<br />

largest ETFE cushion project.<br />

certain extent and need to be calculated carefully.<br />

The overpressure usually amounts to 250 Pa and<br />

can be changed up to the equivalent snow load, if<br />

necessary.<br />

Owing to the instability in windy conditions, a<br />

lack of air pressure should be avoided. If water<br />

ponding is excluded by well designed slopes on the<br />

roof, a lack of air pressure is usually not a static<br />

danger. The foils are designed for the expected loads<br />

and it is not important, whether, for example, snow<br />

load effects are applied to the inner layer via air<br />

cushion or applied directly.<br />

EXTERNAL LOAD E.G. SNOW<br />

HORIZONTAL<br />

SUPPORT<br />

REACTION<br />

INTERNAL OVER PRESSURE<br />

VERTICAL<br />

SUPPORT<br />

REACTION<br />

RADIUS OF OUTER FOIL<br />

OUTER<br />

INNER<br />

RISE<br />

OF<br />

ARCH<br />

Limited strength of ETFE foil<br />

The performance of a cushion-carrying load is<br />

dependent on the deployed thickness of the foil<br />

which is usually between 150 and 250 microns and<br />

on its radius of curvature. With typical building<br />

code design loads, the free span of a long,<br />

rectangular ETFE cushion, can reach up to<br />

approximately 4 m. Its length is limited only by<br />

practical considerations.<br />

High tension forces at the attachment structure<br />

and/or the space for the dip, must be taken into<br />

account. A radius of 3.5 m to 4 m for the curvature<br />

of a cushion layer between the attachment lines, is<br />

a good value to start with, for the design. A small<br />

radius reduces stress but increases the rise of the<br />

arch of the cushion foils.<br />

Supported with cable nets, to reduce the static<br />

free span of the foil, ETFE cushions have been built<br />

with up to 50 m in diameter.<br />

Safe air supply<br />

The normal excess pressure of 250 Pa equals 0.0025<br />

bar or 0.25 kN/sqm. The surplus amount of air<br />

required to provide this pressure in the cushion, is<br />

only a few litres. The air to fill the cushions and to<br />

replace losses, is led into the cushions via pipes and<br />

hoses, and is usually taken from outside of the<br />

building.<br />

Except under extremely windy conditions or<br />

when there is a danger of water ponding, the air<br />

overpressure in the cushion is not a vital element in<br />

the static performance of the cushions. But lack of<br />

air pressure could have negative effects on inner<br />

foils, internals, thermal insulation and durability of<br />

the entire construction.<br />

Usually, two electric engines with two fans (not<br />

Continued on page 5 >>>

Feature: Translucent & Transparent Materials<br />

>>> Continued from page 4 The dryer’s power will hardly exceed 4 kW for<br />

compressors) are installed in the air supply unit,<br />

providing air for the entire roof of a medium sized<br />

building. On large buildings, more units share the<br />

cushion area. Each of the two fans in a unit is<br />

designed to deliver the full supply. For safety<br />

reasons, they alternate weekly and provide back up<br />

for each other.<br />

Additionally, the fan units can be connected to<br />

an emergency power system. In huge buildings, it<br />

may be possible to connect the pipework for the<br />

different units manually, thus providing a second<br />

level of backup.<br />

Unlike in the case of compressors, the noise levels<br />

for the fan units can easily be kept under 55 dB (1 m<br />

distance). For average buildings, the power of the<br />

fans will not exceed 0.8 kW.<br />

Typical Air Supply Fan Unit, placed<br />

outdoor. Inset: Two independent fans<br />

inside.<br />

Climate control in the cushion<br />

ETFE is permeable to steam. Therefore, internal air<br />

conditioning for the cushions at green houses or<br />

swimming baths is strongly recommended:<br />

Steam trapped in the cushion condenses and can<br />

cause water accumulation resulting in algal growth<br />

in the long-term. With well designed options for air<br />

exchange in the cushions, in combination with dryer<br />

devices, the internal spaces remain dry and clean.<br />

Very advanced systems use a closed circle for the<br />

conditioned air with inlet pipe and outlet pipe,<br />

Others work with small outlet openings in the<br />

cushion, at the end of the inlet, opposite the hose,<br />

to provide air exchange.<br />

�<br />

�<br />

Gas Station, Munich, Germany: Horizontal <strong>Roof</strong> Cushions.<br />

an average building and it will work only if the<br />

control devices for air humidity and temperature<br />

determine the need.<br />

Thermal insulation of the cushion<br />

If thermal insulation is demanded, additional,<br />

thinner ETFE foils can be installed outside or inside<br />

the cushions to divide the cushion space into two<br />

or even three air chambers. With two chambers, a<br />

u-value of about 2 can be achieved. With up to four,<br />

it can be reduced to 1.5 or less, depending on<br />

conditions like volume and slope. An inner layer,<br />

in combination with printed patterns on the foils<br />

and special air management, can allow for special<br />

effects with changing optic impressions.<br />

Thermal insulation of attachment extrusion<br />

and condensed water<br />

Usually, the attachment extrusion is the thermal<br />

weak point, causing water to condense from the<br />

humid air inside the building. This water usually is<br />

collected and led away via a small gutter.<br />

With more effort, the thermal losses along the<br />

usual attachment extrusions can be eliminated. It is<br />

possible to attach the outer foil along the upper edge<br />

of support beams and the inner foil along the lower<br />

edge. The cushion foils are not welded together, but<br />

installed one on the outer, and the other, on the inner<br />

surface, of the roof’s support structure. The support<br />

structure ends up as a boundary element for the<br />

cushion, partly situated within the cushion.<br />

Internals in cushions<br />

The space between the two attachment levels can<br />

contain elements of the support structure.<br />

Additionally, the space is sometimes filled with<br />

fixed or retractable sun protection devices or solar<br />

power equipment. Owing to the difficult access,<br />

these should be maintenance-free, as far as possible.<br />

Then, additional measures are strongly<br />

recommended to avoid damage, in case of an<br />

emergency, as when high snow loads might result<br />

in a failure of the air support.<br />

Slope at the eaves of roofs<br />

Basically, to avoid the danger of water ponding, in<br />

case of an air supply break down, it is important to<br />

have steep eaves which allow for snow and water<br />

to fall off the ETFE cladding.<br />

It is important to keep in mind, that although a<br />

flat slope causes snow to slip, it might jam at the<br />

eaves’ support structure causing problems when<br />

there is lack of air pressure.<br />

Water ponding in flat roofs<br />

In case of air supply failure, collapsed cushions in<br />

flat roofs might collect water, establishing a pond.<br />

If it contains too much water, the repaired air supply<br />

will not be able to get rid of it. For cushions with a<br />

geometry conducive to ponding, measures to pump<br />

off the water must be prepared, to enable re-inflation<br />

of the cushion. But emergency pumping can be<br />

acceptable only for buildings with few small<br />

cushions and easy access.<br />

For huge buildings like Allianz-Arena Soccer<br />

Stadium, Munich, with more than 1,800 horizontal<br />

roof cushions, 40 m to 50 m above the ground,<br />

pumping would certainly be a hard job.<br />

<strong>Roof</strong>&<strong>Facade</strong> Asia<br />

Masoala Rainforest, Zurich Zoo, Switzerland: Light and Space with<br />

ETFE-cushions in roofs and facades.<br />

Thermal impact on buildings<br />

ETFE has a very high transmission rate for solar<br />

radiation. This is often underestimated by energy<br />

calculations for internal summer temperatures. It is<br />

helpful, to allow for retractable roof parts or vents<br />

with a good air exchange rate during summer.<br />

The low reflection rate for infrared radiation also<br />

leads to a stronger cooling down effect in clear cold<br />

winter nights, with the thermal radiation from the<br />

building’s floors escaping into space. Both effects<br />

can be reduced with a retractable screen system in<br />

or underneath the cushions.<br />

Special structural tasks<br />

Beside the above points, the engineer in-charge is<br />

always confronted with new challenges. With<br />

reference to the Allianz Arena Soccer Stadium<br />

incorporating 2784 cushions which cover<br />

approximately 65,000 sq m, there are 1,392 different<br />

shapes of cushions, and peaked corners which are<br />

rhombus shaped.<br />

A self-acting ETFE cushion drainage system addresses<br />

the issue of ponding. An advanced attachment and<br />

sealing system takes care of linear offsets and the twisted<br />

geometry of the support structure.<br />

An advanced attachment system with a flexible<br />

base and sealing, counteracts the impact of the<br />

primary structure’s expansion joints on the<br />

cushions.<br />

Prospects with single layer ETFE<br />

The cushions at Allianz Arena are architectural<br />

elements, protecting the facade as additional skin,<br />

without any demand for thermal insulation. For that<br />

low degree of requirement, ETFE allows for an<br />

alternative to cushions. ETFE cladding can be built<br />

also as mechanically prestressed single layers. The<br />

main advantages are that only one foil is needed<br />

instead of two, and no air supply is necessary.<br />

ETFE single layer detailing and engineering,<br />

especially in accordance with existing building<br />

codes and load standards, is a challenge.<br />

Summary<br />

The use of this material requires a deep knowledge<br />

about its mechanical behaviour. The requirements<br />

for manufacturing, installation and maintenance<br />

must merge with the architect’s intentions and the<br />

limitations set by the main support structure and<br />

the load conditions.<br />

On top of that, government approvals are<br />

necessary for a new construction material, since data<br />

cannot be found in any building codes. RnF<br />

(Note: This is an edited version of the presentation)<br />

Photo credits for all images: covertex GmbH, Germany.<br />

<strong>Roof</strong> & <strong>Facade</strong> Asia • <strong>Sep</strong>tember 2004 5

<strong>Roof</strong>&<strong>Facade</strong> Asia<br />

6 <strong>Roof</strong> & <strong>Facade</strong> Asia • <strong>Sep</strong>tember 2004<br />

Translucent & Transparent Materials • Solar Control<br />

New generation polycarbonate<br />

sheets from GE Advanced Materials<br />

GE ADVANCED Materials, a division of General<br />

Electric Company, acquired key plant and<br />

equipment assets of CARBORON Sdn Bhd in August<br />

2002 to position its Structured Products Business<br />

closer to its customers in the Asia Pacific region.<br />

Investments were made to upgrade the<br />

manufacturing facility, in terms of premises,<br />

equipment, capability and human resources. The<br />

multiwall polycarbonate sheet extrusion facility was<br />

officially opened in Klang, Selangor State, West<br />

Malaysia, in January 2003.<br />

Currently, the company produces high quality,<br />

weather- and impact- resistant, multiwall,<br />

polycarbonate sheets, under the LEXAN and<br />

CARBORON brands. The multiwall polycarbonate<br />

sheets are used in various industries ranging from<br />

building and construction, interior decoration and<br />

signage.<br />

The newly developed series of polycarbonate sheets<br />

from GE Advanced Materials, Plastics Malaysia,<br />

incorporates advanced technology to facilitate natural<br />

climatic control, reduce maintenance costs and improve<br />

weathering performance.<br />

LEXAN THERMOCLEAR Easy Clean Sheet is<br />

part of the LEXAN THERMOCLEAR range of<br />

Enquiry No: 09/104<br />

lightweight, weather- and impact- resistant sheets<br />

extruded from LEXAN resin.<br />

LEXAN THERMOCLEAR Easy Clean Sheet<br />

features a special coating on the outer surface, that<br />

possesses self-cleaning properties, as well as UV<br />

protection on both sides; twin, triple and Xstructures;<br />

good light transmission; ease of<br />

installation; long-term weather resistance; high<br />

impact strength; and good thermal insulation.<br />

LEXAN THERMOCLEAR Easy Clean Sheet has<br />

a variety of applications in the building industry. It<br />

can be used for conservatories, balconies,<br />

greenhouses and garden centres, and as covers for<br />

swimming pools.<br />

LEXAN THERMOCLEAR Hammered Glass Look<br />

is a two-sided, UV-protected polycarbonate<br />

multiwall sheet. Apart from its aesthetic attraction,<br />

LEXAN THERMOCLEAR Hammered Glass Look<br />

also contributes to improved light diffusion, safe<br />

interior glazing and ease of installation. It has good<br />

impact resistance, low weight, good thermal<br />

insulation and good fire resistance. LEXAN<br />

THERMOCLEAR Hammered Glass Look can be<br />

used for conservatory roofing and swimming pool<br />

covers, among other applications.<br />

GE Advanced Materials is a world leader in<br />

providing materials solutions through engineering<br />

thermoplastics, silicon-based products and<br />

technology platforms, and fused quartz and<br />

ceramics. Headquartered in Pittsfield,<br />

Massachusetts, USA, GE Advanced Materials is the<br />

entity created by the combination of GE’s former<br />

Plastics, Silicones and Quartz businesses.<br />

GE Advanced Materials, Plastics is a leading<br />

global manufacturer and distributor of plastics<br />

resins used in a number of industries including<br />

building and construction. GE Advanced Materials,<br />

Plastics manufactures and compounds a number of<br />

types of resins. The company also includes GE<br />

Advanced Materials, Structured Plastics, a global<br />

leader in the manufacture of high-performance<br />

LEXAN sheet and film products used in<br />

innumerable applications and industries.<br />

GE Advanced Materials, Silicones which includes<br />

GE Toshiba Silicones in the Pacific Region and GE<br />

Bayer Silicones in Europe, offers several products<br />

for a variety of industries including building and<br />

construction. RnF<br />

Transparent polymer glazing from GE reduces<br />

interior heat buildup<br />

TWO new families of transparent, solar-control<br />

glazing products in monolithic and multi-wall<br />

polycarbonate sheet, from GE Advanced Materials,<br />

significantly reduce solar transmission while<br />

simultaneously offering high levels of light<br />

transmission, thereby helping to save energy costs for<br />

the cooling and lighting of buildings. The single-wall<br />

product is called LEXAN EXELL Solar Control IR<br />

sheet, and the multi-wall product is called LEXAN<br />

THERMOCLEAR Solar Control IR sheet. Both<br />

products are recommended for roof domes, skylights,<br />

walkways, conservatories, and other building<br />

applications where it is desirable to admit high levels<br />

of light while keeping excess heat to a minimum.<br />

According to GE Advanced Materials, LEXAN<br />

sheet can reduce interior heat buildup by up to 40%<br />

for lower energy usage, while increasing light<br />

transmission by as much as 60%. It has good flame<br />

resistance, building-code approval with EU and ICBO,<br />

and other high-performance properties.<br />

GE’s new heat-management glazing makes use of<br />

an entirely new technology platform. Instead of being<br />

translucent or opaque as previous products, the<br />

LEXAN Solar Control sheet materials are transparent<br />

with a green tint which blocks near-infrared heat but<br />

lets in high levels of light. Proprietary resin additives<br />

are used to manage heat instead of expensive and<br />

fragile coatings which can be damaged during<br />

handling and installation. Since the GE additive<br />

technology is inherent to the polymer, solar control<br />

is virtually permanent and provides UV protection to<br />

both sides of the sheet.<br />

The new LEXAN Solar Control IR sheet products<br />

are available in all standard gauges and dimensions.<br />

As with conventional monolithic and multi-wall<br />

LEXAN sheet, this new glazing offers design freedom<br />

due to its ability to be cold formed and/or<br />

thermoformed without losing impact or weathering<br />

properties. Both versions come with a 10-year written<br />

limited warranty against reduction of light or solar<br />

transmission properties, yellowing, and breakage due<br />

to hail impact. RnF<br />

Enquiry No: 09/103<br />

LEXAN sheet can reduce interior heat<br />

buildup by up to 40%, while increasing<br />

light transmission by as much as 60%.

Translucent & Transparent Materials • Solar Control<br />

<strong>Roof</strong>&<strong>Facade</strong> Asia<br />

The Emerald Le’ Magic Glass from<br />

Le-Gardien Singapore<br />

(LOW-RES)<br />

PIX A<br />

Windows can be made opaque for greater privacy within a room, or the transparency can be restored, for a good view of the outside.<br />

INCORPORATED in Singapore in 1997, Le-Gardien specialises in the supply<br />

of glass products for architectural and interior design applications.<br />

One of the products that Le-Gardien has introduced is Emerald Le’ Magic<br />

Glass which can be widely used on windows, skylights, internal partitions<br />

and advertising display screens. Based on PA-LC (Polymer-Assembled<br />

Liquid Crystal) technology, Emerald Le’ Magic Glass enables windows to<br />

SSG DURACOMFORT Insulating Glass Unit<br />

DURACOMFORT Insulating Glass Unit / Double-<br />

Glazed Unit, from Singapore Safety Glass (SSG), is a<br />

high quality insulating glass unit that is constructed<br />

with two or more plies of glass, separated by a<br />

desiccant-filled spacer and sealed with inorganic<br />

sealant. The desiccant absorbs moisture. The spacers<br />

used are available in mill or black anodised finish.<br />

A primary seal of polyisobutylene is incorporated<br />

into the system, which provides maximum protection<br />

against water vapour transmittance. It also helps<br />

reduce thermal edge conductance between spacer and<br />

glass, thereby increasing energy savings.<br />

DURACOMFORT also offers a choice of secondary<br />

sealant, providing versatility in product application<br />

and assuring maximum strength and protection from<br />

stress and extreme temperature.<br />

Insulation<br />

The enclosed layer of air increases the insulation<br />

capability of DURACOMFORT. As a result, the<br />

airconditioning load is greatly reduced. The use of heat<br />

absorbing glass, heat reflective glass and Low-E glass<br />

will further reduce the load on the cooling system.<br />

Preventing dew formation<br />

With monolithic glass, the temperature difference<br />

between the outside and inside of a room will often<br />

lead to condensation. With DURACOMFORT, the<br />

insulating effect of the air layer makes it difficult for<br />

the glass to become cold and consequently dew<br />

formation is less likely to occur.<br />

Sound insulation<br />

DURACOMFORT can significantly save on the cost to<br />

reduce exterior noise pollution. The amount of sound<br />

reduction depends on the configuration of the<br />

insulating glass.<br />

Pleasant indoor environment<br />

With its high insulation properties, the elimination of<br />

cold or warm draughts, leads to a pleasant internal<br />

environment.<br />

DURACOMFORT offers maximum protection from stress and extreme temperature, and provides versatility in product application.<br />

Design flexibility<br />

DURACOMFORT allows for design flexibility, with<br />

combinations of varying thicknesses and glass types,<br />

to suit the requirements of different performance levels.<br />

SSG was incorporated in 1989 with the aim of<br />

providing solutions and high-quality architectural<br />

glass products for the local and regional markets. The<br />

company’s constant focus on developing new products<br />

has made it possible for architects and designers to<br />

push for further creativity in their designs.<br />

SSG is also the first architectural glass manufacturer<br />

in the region to obtain an ISO 9001 certification. The<br />

(LOW-RES)<br />

PIX B<br />

be opacified or made transparent, through the simple operation of<br />

an electrical power switch. A new film version of the PA-LC range of<br />

products, which can be pasted onto any existing glass, is also available at a<br />

much lower cost. RnF<br />

Enquiry No: 09/105<br />

company has also attained the AS/NZS (Australian<br />

Standard / New Zealand Standard) 2208 for safety<br />

glass.<br />

To offer a total architectural glass solution to its<br />

customers, SSG established a subsidiary in Malaysia, SSG<br />

Safety Glass Sdn Bhd, to produce tempered safety glass<br />

as well as ceramic frit glass. The company has also entered<br />

into a joint venture in United Reliance Engineering Pte<br />

Ltd (URE), to provide design, supply and installation<br />

services in structural glazing systems. RnF<br />

Enquiry No: 09/106<br />

<strong>Roof</strong> & <strong>Facade</strong> Asia • <strong>Sep</strong>tember 2004 7

<strong>Roof</strong>&<strong>Facade</strong> Asia<br />

8 <strong>Roof</strong> & <strong>Facade</strong> Asia • <strong>Sep</strong>tember 2004<br />

Translucent & Transparent Materials • Solar Control<br />

Solar control glass with enhanced<br />

thermal insulation<br />

SGG COOL-LITE from Saint-Gobain Glass (SGG) is<br />

a solar control glass offering numerous aesthetic<br />

choices in the design of facades. It is available in a wide<br />

range of colours and by combining thicknesses and<br />

colours with clear or body-tinted glasses, an extensive<br />

selection of appearance and performance options can<br />

be made available.<br />

SGG COOL-LITE is manufactured through the<br />

deposition of a coating of metal oxides by magnetically<br />

enhanced cathodic sputtering, under vacuum<br />

conditions, on to clear float glass, SGG PLANILUX, or<br />

on to body-tinted glass, SGG PARSOL.<br />

The type of coating applied to the glass determines<br />

its aesthetic appearance and colour.<br />

Careful selection of the most appropriate type of<br />

SGG COOL-LITE for each application makes it<br />

possible to satisfy several design criteria<br />

simultaneously, including solar control and<br />

therefore more economical use of airconditioning;<br />

aesthetic appearance, in terms of colour and<br />

reflection; and light transmittance.<br />

The overall result depends on the orientation,<br />

environment and geographical location of the building.<br />

SGG COOL-LITE K and SGG COOL-LITE SK are solar<br />

control glasses with enhanced thermal insulation.<br />

SGG COOL-LITE K and SGG COOL-LITE SK are<br />

produced through the deposition of several coats of<br />

metallic oxides by magnetically enhanced cathodic<br />

sputtering, under vacuum conditions, on to SGG<br />

PLANILUX, SGG DIAMANT and SGG PARSOL.<br />

SGG COOL-LITE K and SGG COOL-LITE SK which<br />

must always be in double-glazed form, provide a<br />

spectrally selective range of solar control performances<br />

together with good thermal insulation properties.<br />

Each of the 6 glass types in the SGG COOL-LITE K<br />

and SGG COOL-LITE SK ranges, enable different<br />

performance levels to be achieved.<br />

SGG COOL-LITE KS 147 is distinguished by its<br />

silvered appearance, low solar factor g, and low heat<br />

transmittance or U value.<br />

SGG COOL-LITE KN 155 and KN 169 are neutral<br />

SGG COOL-LITE has been specified for Singapore Management University’s School of Business building.<br />

in appearance and have a low light reflectance. They<br />

combine high light transmittance with a low solar<br />

factor g and a good U value.<br />

In addition to its high performance levels, SGG<br />

COOL-LITE KB 159 has a distinctive bluish appearance<br />

in reflection.<br />

SGG COOL-LITE SKN 172 and SKN 165, the latest<br />

K-LITE sputter coated low emissivity glass<br />

GLASSLINK Trading of Singapore is the agent for Saudi American Glass Factory (SAGF) of Riyadh, Saudi Arabia, the<br />

manufacturer of K-LITE high performance glass.<br />

One of the products, K-LITE low emissivity (low-E) coated glass offers designers and specifiers, the opportunity to<br />

achieve greatly improved thermal performance, while still maintaining the appearance of uncoated glass. It is ideal for<br />

applications requiring subdued colours, low reflectance and abundant daylight.<br />

K-LITE low-E and K-LITE OPTIMA are ultra-thin coatings which are applied to the float glass substrate by magnetically<br />

enhanced cathodic sputtering.<br />

K-LITE low-E and K-LITE OPTIMA coatings are almost invisible and yet are highly effective in reducing the transmission<br />

of heat energy in the long-wave infrared (IR) frequencies, while freely admitting visible light. RnF<br />

Enquiry No: 09/108<br />

(LOW-RES)<br />

K-LITE products offer designers and specifiers the opportunity to achieve greatly improved thermal performance.<br />

innovations in the SGG COOL-LITE SK range, offer<br />

high performance levels. They are neutral in<br />

appearance, with low light reflectance, combining high<br />

light transmittance with a low solar factor g and a good<br />

U value. RnF<br />

Enquiry No: 09/107<br />

(LOW-RES)<br />

K-LITE glass is installed on the Al-Faisaliyah Center, Riyadh,<br />

Saudi Arabia.

Translucent & Transparent Materials • Solar Control<br />

SUN-X films for increased<br />

safety and solar control<br />

AUTHORITIES in every country are today concerned about the need for greater<br />

security and safety of human lives and property.<br />

When buildings are destroyed through intentional means such as terrorism or arson<br />

attacks, or through unintentional means such as accidents or natural calamities,<br />

the glass on the facades of buildings, for all its beauty, can shatter, with the shards<br />

becoming extremely dangerous projectiles.<br />

An action plan to prevent this from happening, according to SUN-X Film, involves<br />

the application of the company’s ARMORCOAT Safety and Security Films.<br />

ARMORCOAT Safety and Security Films are designed to make glass stronger by<br />

up to 300%, as well as render it shatter-resistant. In the event of deliberate or accidental<br />

glass breakage, the strong adhesive, as well as the multi-layered polymer, will help<br />

hold the glass fragments or shards together as an integral piece, preventing injuries to<br />

people in the vicinity. They are offered in thickness ranges from 4 mil (100 microns) to<br />

14 mil (350 microns). ARMORCOAT Safety and Security Films are available in three<br />

models - Clear, Grey and Bronze.<br />

ARMORCOAT Safety and Security Films are offered in clear or solar performing<br />

versions, with a film thickness ranging from 4 mil to 14 mil. They reject 98% of the<br />

harmful ultraviolet light. Safety Solar versions reject up to 81% of solar energy.<br />

ARMORCOAT Safety and Security Films help to hold the glass in place, in case of<br />

breakage. The films are manufactured with the DUROGARD scratch-resistant coating,<br />

and are easy to clean. ARMORCOAT Safety and Security Films are backed by strong<br />

warranties.<br />

SUN-X Solar Control Films<br />

Since its incorporation in 1968, SUN-X has been providing solar control films using<br />

advanced technology which has its origins in advanced materials research and development<br />

programmes for aerospace applications.<br />

SUN-X Solar Control Films help to substantially reduce solar heat penetration<br />

through glass, thereby contributing to lower airconditioning loads and<br />

energy savings. Another advantage of SUN-X solar control films is their ability<br />

to control glare which causes eye strain and fatigue. Further, SUN-X films come<br />

with UV inhibitors which absorb almost all UV radiation that can otherwise<br />

�����<br />

�����<br />

(LOW-RES)<br />

SUN-X films are used on the glass surfaces of modern facades.<br />

(LOW-RES)<br />

<strong>Roof</strong>&<strong>Facade</strong> Asia<br />

cause discoloration of upholstery, carpets and furniture.<br />

There are also the aesthetic benefits of window tints and additional safety, that the<br />

SUN-X Solar Control Films can provide.<br />

SUN-X Conventional Premium Films provide efficient protection against radiant<br />

heat, glare and ultraviolet light. They are available in Grey, Silver, Bronze and<br />

Gold.<br />

SUN-X Sputtered High Grade Films cater primarily to those who want effective<br />

reduction in radiant heat without compromising the transmission of visible light. Continuous<br />

roll to roll sputtering is a process which permits controlled, repeatable deposition<br />

of a wide range of materials such as pure metals, alloys, metal oxides and nitrides.<br />

The vacuum process allows ‘atom by atom’ layering of these materials to produce a<br />

technically superior window film. SUN-X Sputtered High Grade Films are available<br />

with titanium, stainless steel or copper layers.<br />

SUN-X Specialty Films provide privacy and creativity to any home or office. A wide<br />

range of designs is available to suit every need.<br />

SUN-X Residential Films reject almost 100% of damaging ultraviolet and up to 82%<br />

of total solar energy, thus providing protection to valuable furnishings, flooring and<br />

decor.<br />

SUN-X Residential Films complement any style and are available in a variety of<br />

shades, colours and performance levels, from lighter, more subtle films, to more reflective<br />

films for greater privacy and higher performance. SUN-X Residential Films also<br />

incorporate the scratch-resistant DUROGARD coating.<br />

SUN-X Film believes that on account of its long experience in the field, it can offer<br />

professional advice in all situations, to ensure the safety, security and comfort levels of<br />

the occupants and those in the vicinity of modern buildings. RnF<br />

Enquiry No: 09/109<br />

<strong>Roof</strong> & <strong>Facade</strong> Asia • <strong>Sep</strong>tember 2004 9

<strong>Roof</strong>&<strong>Facade</strong> Asia<br />

10 <strong>Roof</strong> & <strong>Facade</strong> Asia • <strong>Sep</strong>tember 2004<br />

Translucent & Transparent Materials • Solar Control<br />

Glass application at Hangar 7<br />

of Salzburg Airport<br />

THE new Hangar 7 at Salzburg Airport in Austria, is<br />

located on the east side. Architect Volkmar Burgstaller<br />

has designed the highly regarded steel and glass structure.<br />

From floor to ceiling, uninterrupted spans of fireresistant<br />

glass, made by SCHOTT JENAer GLAS of Germany,<br />

for the first time in these dimensions, bring the<br />

desired transparency and lightness via the glazed facades,<br />

right into the interior of the building.<br />

In geometrical terms, the futuristic steel structure<br />

alongside the taxiway is an ellipsoid, turned slightly on<br />

its longer axis and sunk into the ground, resulting in the<br />

largest possible cross-sectional area. The impressive dome<br />

rises up in an unsupported 66 m x 95 m span, to an overall<br />

height of more than 14 m. On the northern side, the<br />

ellipsoid is cut away on the diagonal, to open up a 350 sq<br />

m gate, on to the taxiway and runway, providing a view<br />

of the airport terminal building.<br />

Two 5-storey cylindrical glass towers are built into the<br />

hangar on its southeast side. Bridges and galleries link<br />

them together and ensure that the main structure is solid.<br />

The main entrance is located between them, giving access<br />

to both the exhibition and the catering facilities. The<br />

Skywalk leads, via the terrace, in front of the first-floor<br />

restaurant, to the Skybar suspended below the dome,<br />

which has glass floors and walls, to provide a view from<br />

the highest point of the structure.<br />

‘The maximum expanse of glass supported by the<br />

smallest possible steel profiles’ was the specification presented<br />

to Waagner Biro Stahl-Glas-Technik AG for the<br />

design of the glazed roof. The diameter of the steel tubing,<br />

which had to be bent to achieve the varying radius,<br />

had to be kept to less than 406 mm. After numerous calculations,<br />

the design, especially the way the ellipsoid and<br />

glass towers combined, was optimised to meet the required<br />

specification. The fact that there is an overhang<br />

on one side of the hangar shell, resulting from the slight<br />

turn on the ellipsoid, was an extra challenge in all of this,<br />

as was the uppermost area of the shell, which presented<br />

a leakage problem resulting from its low curvature. The<br />

solution was a suspension in the dome area, in a geometrically<br />

adapted form which now supports the Skybar.<br />

In other areas, horizontal rings and infills were added to<br />

the radial support structure, to stiffen it.<br />

The secondary structure required to support the<br />

glass, consists of flat steel members welded to a support<br />

frame. The whole shell of the hangar is enclosed<br />

in laminated safety glass. This is point-bolted and bent<br />

in some parts. It is silk-screened on the outer surface<br />

to provide solar protection. The largest panes, at<br />

around 5 m x 2 m in size, are at the limit of what is<br />

technically feasible.<br />

The facades of the two cylindrical glass towers are in<br />

the form of a double skin. The inner skin is insulating<br />

glass with a solar control and heat protection function.<br />

The individual panes go from floor to ceiling without any<br />

other support on each floor. The gap between the inner<br />

and outer skins is ventilated and incorporates concealed<br />

solar protection in the form of external blinds. The external<br />

shell itself also consists of floor-to-ceiling, point-supported<br />

laminated glass panes which are supported without<br />

frames via glass blades and which can be opened for<br />

cleaning purposes.<br />

The building control authority required fire protection<br />

compartmentalisation at the structural interface between<br />

the glass towers and the hangar. To comply with<br />

the wishes of the architect and the building owners, this<br />

also had to be in glass. A special difficulty in this connection<br />

was the fact that the slight turn on the ellipsoid, resulted<br />

in the facade overhanging in places in this area.<br />

From an extreme inclination of 12°, it progresses continu-<br />

PYRAN S borosilicate fire-resistant glass at Hangar 7 has opened up a new dimension of transparent architecture in a format previously unattained in frameless glazing.<br />

ously to the perpendicular at the point where the glazed<br />

double doors are fitted, providing access from the foyer<br />

to the exhibition hall. Fitting a succession of diamondshaped<br />

panes, over the 4 m length of the side edge, would<br />

have created the risk of a 4 cm bow, with the consequent<br />

danger of structural damage at a later date. In order to<br />

butt the glass together without bow, in other words, to<br />

deal with both the inclination and the horizontal succession<br />

of polygons, the panes of glass were based on a<br />

frustum and produced as distorted diamond shapes, the<br />

actual glass being flat. As a consequence the joints are<br />

not parallel, and the panes of glass appear to be tilted<br />

outwards. The greater the inclination, the more obvious<br />

this becomes.<br />

The contract for this specially produced fireresistant<br />

glass went to the Special Float Glass Division of<br />

SCHOTT JENAer Glas GmbH. The company says that<br />

PYRAN S borosilicate fire-resistant glass at Hangar 7<br />

has opened up a new dimension of transparent<br />

architecture in a format previously unattained in<br />

frameless glazing. The fire-resistant glass separates the<br />

two fire-protection compartments over a floor height of<br />

up to 3.40 m. It is supported without the use of vertical<br />

profiles from floor to ceiling, with the supports required<br />

‘concealed’ in the floor covering and ceiling cladding. The<br />

company supplied, among other things, 20 t of double<br />

pane PYRAN S 10 mm thick laminate, 65 of which alone<br />

measured 1200 mm x 3400 mm. Other pieces were made<br />

to templates and had edge cutouts of up to 65% of the<br />

glass area, or were made as stepped insulating glass.<br />

Some adaptation of the production had to be carried out<br />

both for the manufacture of the basic glass and also for<br />

the toughening and laminating. RnF<br />

Enquiry No: 09/110

Translucent & Transparent Materials • Solar Control<br />

<strong>Roof</strong>&<strong>Facade</strong> Asia<br />

Elegant curved glass replaces old zinc in<br />

the roof of the Kenzo Building in Paris<br />

IN a prestigious quarter in central Paris, a new glass roof now<br />

soars over Kong, the celebrated Japanese restaurant. Elegant<br />

and refined, it highlights the Kenzo boutiques located on the<br />

lower floors of the same building.<br />

While designing the glass roof, in order to meet the project’s<br />

demanding specifications, the architects at Studio<br />

d’Architecture Jean-Jacques Ory selected Glaverbel<br />

SUNERGY, an extremely clear low-emissivity solar-control<br />

glazing.<br />

The first objective was to comply with the standards imposed<br />

by the City of Paris relating to its historical heritage, by<br />

opting for a clear glass with the lowest possible level of light<br />

reflection. The second important consideration was to find a<br />

glass that could be curved to fit the conical section of the arch<br />

in the roof. The third goal was to find a high-performance<br />

double glazing assembly that could be curved, laminated and<br />

toughened, while at the same time ensuring optimal comfort<br />

for restaurant patrons, regardless of the weather.<br />

All the factors in this complex scenario indicated that<br />

SUNERGY solar-control glazing would be the solution. With<br />

its neutral, ‘super high performance’ hard coating, it is a glazing<br />

that can be easily processed in such a way as to fulfil the<br />

above requirements.<br />

The SUNERGY glass is mounted in a thin metal frame, allowing<br />

Kong’s patrons to appreciate the view of the river<br />

Seine. The glass is curved in the lateral part of the roof and<br />

arched in two directions in the spherical tip, forming a sort of<br />

prow overhanging the Pont Neuf neighbourhood. Some of<br />

the glasses are toughened, while others are toughened and<br />

laminated. The architectural ensemble can be fully appreciated<br />

from both the inside and outside. RnF<br />

Enquiry No: 09/111<br />

The Kenzo building in<br />

Paris, France, with an<br />

elegant glass roof made<br />

from SUNERGY solarcontrol<br />

glazing.<br />

�<br />

�<br />

<strong>Roof</strong> & <strong>Facade</strong> Asia • <strong>Sep</strong>tember 2004 11

<strong>Roof</strong>&<strong>Facade</strong> Asia<br />

12 <strong>Roof</strong> & <strong>Facade</strong> Asia • <strong>Sep</strong>tember 2004<br />

Translucent & Transparent Materials • Solar Control<br />

Architectural products with solar<br />

control features<br />

HUNTER DOUGLAS offers building designers a range<br />

of products that combine aesthetic appeal and durability,<br />

with solar control features.<br />

LUXALON Sandwich Wall<br />

LUXALON Sandwich Wall systems provide good thermal<br />

and acoustic insulation. Panels are composed of two skins<br />

of pre-coated metal surrounding an insulating core of either<br />

CFC-free polyurethane foam or mineral wool. The surfaces<br />

are either smooth or embossed.<br />

The extremely flat panel surfaces in aluminium or other<br />

metals are available in a great variety of colours and shapes,<br />

in thicknesses of 35 mm, 50 mm, 60 mm, 75 mm and 100<br />

(LOW-RES)<br />

LUXALON Sandwich Wall.<br />

LUXALON Sun Louvre Systems<br />

Solar heat and indoor light can be controlled by installing<br />

shading elements externally. Hunter Douglas manufactures<br />

a variety of shading products including Single<br />

Aerobrise and Double Aerobrise Sun Louvre Systems,<br />

the Aeroscreen System, as well as the Aerofoil Louvre<br />

System.<br />

These systems offer several advantages including the<br />

ability to control and adjust indoor light, eliminate dazzle<br />

and prevent light pollution, prevent mirror reflection, control<br />

indoor temperature and save power, as well as add an<br />

extra dimension to the building.<br />

The Single Aerobrise System can be installed either horizontally<br />

or vertically. The angle of the fin can be locked in<br />

position in increments of 5º, by means of the adjustable<br />

fixing bracket. The Double Aerobrise System can also be<br />

installed, either horizontally or vertically. The angle of the<br />

fin can be locked in increments of 5º, by means of the adjustable<br />

fixing disk.<br />

In the Fixed Aeroscreen System, a fin suspension and<br />

fixing disk control the fin rotation. The angle of the fin can<br />

be locked in increments of 5º. In the Adjustable Aeroscreen<br />

System, an actuator and driving rod control the fin rota-<br />

mm, and in standard widths of 200 mm, 300 mm, 600 mm,<br />

900 mm and 1200 mm. The products can also be offered in<br />

special colours and customised sizes up to 1200 mm in<br />

width. Several joint systems and concealed fixings add to<br />

the architectural possibilities.<br />

The made-to-measure panels can be curved or cranked<br />

either length-wise or width-wise and can be used for both<br />

horizontal and vertical applications. The panels are connected<br />

by means of a ‘secret’ fixing clamp, providing a joint<br />

which has the facility of adjustment and can accommodate<br />

thermal movement.<br />

LUXALON Sandwich Wall has many panel joint details<br />

providing the designer with a number of aesthetic options.<br />

In addition, false joints can be integrated across the width<br />

or the length of a panel, offering even more design possibilities.<br />

Air and water-tightness are ensured through high-performance<br />

concealed gaskets.<br />

LUXAFLEX HELIOSCREEN Intelligent Sun<br />

Control<br />

According to Hunter Douglas, with HELIOSCREEN sun<br />

screening fabrics and systems, it is possible to prevent most<br />

of the solar radiation from entering a building through the<br />

large areas of glass used on the facades of buildings, whilst<br />

the occupants retain a clear view of the exterior. Rooms and<br />

offices still remain bright, yet cool, with enough natural<br />

daylight to make artificial light often unnecessary.<br />

Developed by Helioscreen, which created the first solar<br />

roller blind made from Screenglass fibre-glass fabric in 1963,<br />

these products are widely used in Europe and many parts<br />

of the world. Helioscreen is a member of the Hunter Douglas<br />

Group.<br />

LUXAFLEX HELIOSCREEN fabrics have properties for<br />

controlling light and heat. The glass core of each yarn is a<br />

complex set of spun glass fibres coated with a bulk-dyed<br />

polymer. The woven fabric has good colourfastness and is<br />

tion. The angle of rotation is between 0º and 120º. Two<br />

standard perforation patterns can be incorporated, to satisfy<br />

acoustic applications. Other specially designed panels<br />

are available upon request.<br />

The fin length depends on the wind load, but cannot<br />

be greater than 3800 mm.<br />

The LUXALON Standard Aerofoil Louvre system consists<br />

of six different aluminium-extruded fins, ranging from<br />

200 mm to 450 mm width, in increments of 50 mm. Other<br />

available fin sizes are 100 mm, 150 mm and 500 mm width,<br />

but these do not correspond to the company’s standard<br />

fixing system.<br />

For the standard system, there are two fixing options.<br />

In the non-adjustable system, the fins are installed in a<br />

fixed position with respect to the frame. The angle of the<br />

fins can be locked in increments of 5º, from 0º up to 180º,<br />

and are locked into position while fixing.<br />

In the adjustable motorised system, the angle of the<br />

fins can be set at any angle, from 0º to a maximum of 120º.<br />

Each fin is attached to two axles and aligned with a setscrew.<br />

The driving rod is attached and adjusted. Finally,<br />

the motor is installed to provide the required angle of rotation<br />

for the fins.<br />

LUXALON Sun Louvre Systems. Projects: Building at Bukit Batok St 21 (left), German School, Singapore (right).<br />

LUXAFLEX HELIOSCREEN. Project: Radio & Television<br />

Luxembourg, Belgium.<br />

flame retardant. Its good dimensional stability means that<br />

it always retains its shape and has a particularly long life<br />

expectancy. With its resistance to humidity, rot and dirt, it is<br />

ideal for use both inside and outside. Owing to the nature<br />

of the fabric, maintenance is minimal.<br />

Their high degree of reflectance and low level of transmittance,<br />

mean that LUXAFLEX HELIOSCREEN fabrics let<br />

in only a small percentage of solar radiation. According to<br />

Hunter Douglas, studies have shown that with LUXAFLEX<br />

HELIOSCREEN fabrics mounted externally, the inside temperature<br />

of a building may be decreased between 5º C to<br />

15º C, which contributes to energy savings.<br />

HELIOSCREEN offers a wide range of colour choices.<br />

All systems are made-to-measure. They can be operated either<br />

manually or electrically, and include options for sun,<br />

wind and rain sensors.<br />

HELIOSCREEN systems find application in exterior<br />

sunscreening (as in vertical, exterior sunscreens and awnings),<br />

interior sunscreening (as in vertical interior roller<br />

blinds, vertical blinds and panel screens which are vertical<br />

sliding panels in Screen), horizontal and sloped glazing (as<br />

in sun roofs), special applications (as in total black-out<br />

screens); and in tension fabric systems.<br />

LUXAFLEX DUETTE Honeycomb Shades<br />

LUXAFLEX DUETTE Honeycomb Shades contribute to<br />

energy efficiency. The honeycomb pleat design traps air<br />

within the shade, which acts as a thermal insulator. The<br />

shades are clean and crisp in appearance, with pleats that<br />

hold their shape and fabrics that do not sag or fray. Cords<br />

run through the centre of the shades, out of sight. The honeycomb<br />

construction gives the shades the strength and durability.<br />

Compact stacking heights provide maximum visibility<br />

when shades are raised. The cordlock design permits<br />

easy operation, with the fabric extending the full width of<br />

the window.<br />

(LOW-RES)<br />

LUXAFLEX DUETTE.<br />

LUXAFLEX HARMONY Cellular Verticals<br />

LUXAFLEX HARMONY Cellular Verticals combine lightweight,<br />

dimensional fabric vanes with ease of operation.<br />

The look is refreshing and modern with clean lines and a<br />

hint of colour.<br />

Vanes are soft and have an elliptical ‘pocket cell’ to accommodate<br />

a light filtering or room darkening insert. When<br />

closed, the ‘pocket cell’ vanes form an insulating layer that<br />

helps boost energy efficiency. RnF<br />

Enquiry No: 09/112

German-engineered windows<br />

and doors by REHAU<br />

SINCE 1949, REHAU has been dedicated to<br />

developing and producing high quality polymer<br />

solutions for extrusion and processing into industrial<br />

and construction materials. The company has 44<br />

factories, more than 120 sales offices and 14 training<br />

academies worldwide.<br />

REHAU’s architectural solutions include UPVC window<br />

and door systems. Since 1958, the company has<br />

offered its range of sound and heat insulated windows<br />

and doors. Today, the company has over 200 window<br />

system solutions.<br />

In densely populated cities such as Singapore,<br />

REHAU has achieved popularity in high-end landed<br />

property developments. The company’s products are<br />

characterised by high aesthetic values, good performance<br />

in terms of heat and sound insulation, greater ambience<br />

control and operating durability.<br />

Conforming to the strictest DIN and European Standards<br />

that ensure above-premium quality on all accredited<br />

products, REHAU is committed to the industry, with<br />

its regional headquarters in Singapore and a team of<br />

experienced engineers that provide technical, production<br />

and pre- and post-marketing support to the company’s<br />

fabrication and distribution partners.<br />

Scheduled for launch in Asia in the last quarter of<br />

2004, is the REHAU-Tritec window programme which<br />

offers designers, design solutions with a range of sculptured<br />

profiles. Following the success of the company’s<br />

slim-line UPVC window and door programme in Singapore<br />

since 1989, REHAU-Tritec comes with a 60 mm<br />

Euro base and Euro groove, ready for multi-gear hardware<br />

configurations, and with a wider choice of hardware<br />

options.<br />

The REHAU-Tritec programme includes aesthetic<br />

variations to complement facade designs and independent<br />

glazing inserts on single-sash panel Georgian bars.<br />

This feature empowers the homeowner and designer to<br />

fully utilise the company’s quality concept, with products<br />

made in Germany and customised locally.<br />

Other improvements include an increase from dual<br />

to three chamber sections, providing advancements in<br />

sound and heat insulation. The increased 8 mm sash-toframe<br />

overlap complements the double-seal, sash-toframe<br />

design. Users can expect weatherproofing against<br />

strong winds and heavy rains.<br />

The REHAU-Tritec range comes with a built-in friction<br />

hinge locator that provides accurate alignment and<br />

removes the guesswork in sash-to-frame finishing.<br />

Superior performance<br />

with UPVC<br />

SINCE 1969, VEKA has been providing the world with UPVC<br />

window and door profile systems. The company says that UPVC is<br />

a cost-effective, durable and ecologically friendly material, and that<br />

with the right combination of ingredients like stabilisers, pigments<br />

and fillers, optimal quality window and door products can be<br />

manufactured.<br />

Well represented all over the world, with manufacturing facilities in<br />

China, France, Germany, Mexico, Poland, Russia, Spain, UK and USA,<br />

VEKA has more than 2,500 fabricating partners, located on all<br />

continents, who are supported by a worldwide network of sales and<br />

technical support offices.<br />

VEKA offers more than 1,500 window and door profile systems to<br />

meet the functional and aesthetic requirements in any country.<br />

In designing window and door systems for the Asia-Pacific region,<br />

VEKA has taken into consideration the cultural preferences and the<br />

harsh weather. The result is VEKA’s ‘tropical compound’ which is<br />

incorporated in its Softline and VEKA VS range of UPVC profiles.<br />

Accordingly, these systems can withstand intense solar radiation, high<br />

heat and humidity. There is no discoloration and deterioration of the<br />

UPVC window and door systems. RnF<br />

REHAU’s architectural solutions include UPVC window and door systems.<br />

REHAU-Tritec incorporates an 18 mm stack void, to accommodate<br />

heavy-duty sashes, offering greater cost efficiency<br />

for homeowners and a wide array of configuration<br />

choices for designers.<br />

Providing structural and mechanical integrity, the<br />

company uses German imported, single-rolled, industrial<br />

galvanised steel reinforcements for compliance with the<br />

original DIN/EU standards.<br />

REHAU was first in the market to introduce slim-line<br />

profiles, thereby creating window systems with the widest<br />

aperture. Also, the incorporation of an anti-stain, semi-<br />

Enquiry No: 09/114<br />

UPVC Windows & Doors<br />

(LOW-RES)<br />

<strong>Roof</strong>&<strong>Facade</strong> Asia<br />

gloss finish, ensures a low-maintenance requirement<br />

which will be a feature of the REHAU-Tritec system, as<br />

well.<br />

Manufactured with the patented RAU-PVC 1406 formulation,<br />

REHAU-Tritec offers weather- and UV radiationresistance<br />

up to 180 kcal / sq m / year. Incorporating all<br />

these features into the company’s signature, slim-line footprint,<br />

REHAU-Tritec will permit both internal and external<br />

glazing, as well as offer security and safety. RnF<br />

(LOW-RES)<br />

(LOW-RES)<br />

VEKA’s window and door profile systems can meet the requirements in any country.<br />

Enquiry No: 09/113<br />

<strong>Roof</strong> & <strong>Facade</strong> Asia • <strong>Sep</strong>tember 2004 13

<strong>Roof</strong>&<strong>Facade</strong> Asia<br />

Durable UPVC windows and doors<br />

IN 1997, KÖMMERLING celebrated its 100th birthday.<br />

The company is headquartered in Pirmasens, Germany,<br />

and has production sites also in Brazil, China, France,<br />

Italy, Spain and the US. Employing close to 2000 people<br />

worldwide, KÖMMERLING offers a wide spectrum<br />

of UPVC profiles for window sashes and frames, door<br />

systems, roller shutters, folding shutters, balconies and<br />

fencing, as well as special UPVC sheets and panels for<br />

the building and advertising sectors.<br />

UPVC windows and doors from the company contribute<br />

to the aesthetic beauty and harmonious design<br />

of new and old buildings alike whilst functionally they<br />

are characterised by strength, dimensional stability and<br />

durability. KÖMMERLING products comply with the<br />

stringent certification requirements of the British<br />

Standards Institute (BSI).<br />

UPVC windows and doors from the company are<br />

based on a carefully designed profile concept that permits<br />

many different structures with innumerable variants,<br />

including a range of wood-grain finishes.<br />

KÖMMERLING products facilitate the personalised<br />

styling of windows and doors in a variety of shapes,<br />

such as circular, square, rectangular and other polygonal<br />

configurations. Also available are extra large surfaces,<br />

and a variety of transoms and staves.<br />

Maximum water tightness and wind<br />

resistance<br />

KÖMMERLING UPVC window and door systems have<br />

been successfully used in swimming pools, marine and<br />

ocean environments without detriment to the surface<br />

finish or performance.<br />

One of the main assets of KÖMMERLING window<br />

and door systems is their resistance to driving rain<br />

and their joint tightness. KÖMMERLING UPVC<br />

profiles fulfil the demands of DIN 18055 (resistance to<br />

driving rain). All window types are designed to be<br />

watertight when tested up to the 300 PA limit specified<br />

in BS 6375: Performance of Windows Part 1, 1989:<br />

Classification for weather tightness. Some types<br />

achieve a 600 PA rating.<br />

KÖMMERLING UPVC windows and doors are<br />

ideal for installation in buildings close to the sea, where<br />

there is constant exposure to strong wind, heavy rain<br />

and salt-laden air. The windows have passed several<br />

severe tests conducted by official institutions. All window<br />

types are capable of withstanding the tests specified<br />

in BS 5368, Part 3 1978 (wind resistance up to a<br />

wind pressure of 2400 PA). Therefore, KÖMMERLING<br />

profiles can also be fitted in high-rise buildings without<br />

any problems.<br />

UPVC windows for residential applications<br />

WITH over 10 years of experience in the field,<br />

Fascina provides high quality UPVC windows for<br />

homes.<br />

High quality thermoplastic gaskets and an<br />

advanced double sealing system, prevent rain<br />

from seeping in. The company’s multi-chambered<br />

profiles incorporate a drainage system designed<br />

with weep holes and elevated hinges to facilitate<br />

easy drainage, thus keeping homes dry.<br />

Besides providing elegance, Fascina windows<br />

are said to reduce noise levels by up to 43<br />

decibels, achieved by means of the company’s<br />

double-glazing technology, thereby creating a<br />

comfortable environment to live in.<br />

Further, the toughened, galvanized steel<br />

reinforced interiors and special multi-locking<br />

system make the windows strong, durable and<br />

impact resistant.<br />